Fragrance-releasing facing artificial board and preparation method thereof

A wood-based panel and veneer technology, applied in the direction of microsphere preparation, papermaking, special paper, etc., can solve the problem of reducing the effect of fragrance release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

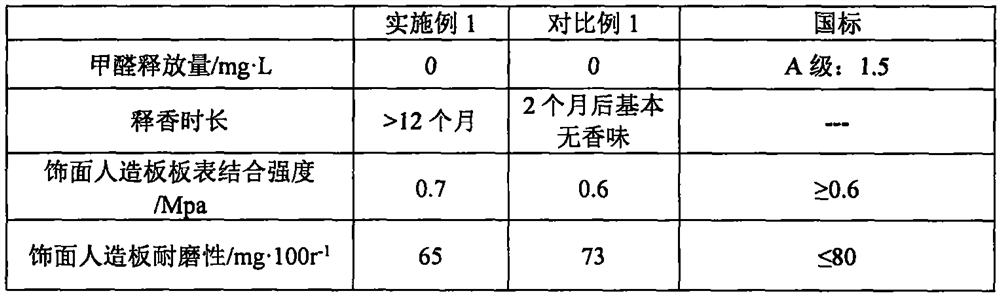

Examples

Embodiment 1

[0029] 1) Put 40 parts of deionized water in a container, heat it in a constant temperature water bath, add 30 parts of gum arabic and 10 parts of maltodextrin into the container in turn, stir to make them fully dissolve, and prepare the wall material;

[0030] 3) Add 20 parts of floral essence to the wall material that has been stirred evenly, stir to make it fully dissolve, and shear at a high speed with a high-pressure homogenizer to form an oil-in-water emulsion; the speed of the high-speed homogenizer is 8000 / min, and the The cutting time is 15 minutes, and the homogeneous pressure is 1000bar.

[0031] 4) The oil-in-water emulsion is spray-dried, the feed rate is 5 / min, the air inlet temperature is 190°C, and the air outlet temperature is 90°C. That is, rose essence-starch-based microcapsules are obtained.

[0032] 5) Completely immerse the decorative base paper in the formaldehyde-free adhesive reported in patent ZL 202010394935.8 for 30s, and dry it at 80°C. The amount...

Embodiment 2

[0035] 1) Put 20 parts of deionized water in a container, heat it in a constant temperature water bath, add 20 parts of gum arabic and 20 parts of maltodextrin into the container in turn, stir to make them fully dissolve, and obtain the wall material;

[0036] 3) Add 40 parts of floral essence to the wall material that has been stirred evenly, stir to make it fully dissolved, and shear at a high speed with a high-pressure homogenizer to form an oil-in-water emulsion; the speed of the high-speed homogenizer is 15000 / min, and the The cutting time is 1 minute, and the homogeneous pressure is 1200bar.

[0037] 4) The oil-in-water emulsion is spray-dried, the feed rate is 40 / min, the air inlet temperature is 150°C, and the air outlet temperature is 70°C. That is, rose essence-starch-based microcapsules are obtained.

[0038] 5) Completely immerse the decorative base paper in the formaldehyde-free adhesive reported in patent ZL 202010394935.8 for 60s, and dry it at 110°C. The amoun...

Embodiment 3

[0041] 1) Put 20 parts of deionized water in a container, heat it in a constant temperature water bath, add 30 parts of gum arabic and 20 parts of maltodextrin into the container in turn, stir to fully dissolve, and obtain a wall material;

[0042]3) Add 30 parts of floral essence to the wall material that has been stirred evenly, stir to make it fully dissolved, and shear at a high speed with a high-pressure homogenizer to form an oil-in-water emulsion; the speed of the high-speed homogenizer is 10,000 / min, and the The cutting time is 10 minutes, and the homogeneous pressure is 800bar.

[0043] 4) The oil-in-water emulsion is spray-dried, the feed rate is 20 / min, the air inlet temperature is 160°C, and the air outlet temperature is 80°C. That is, rose essence-starch-based microcapsules are obtained.

[0044] 5) Completely immerse the decorative base paper in the formaldehyde-free adhesive reported in patent ZL 202010394935.8 for 45 seconds, and dry it at 100°C. The amount of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com