Fiber-based humidity sensor based on moisture absorption and color change, and preparation method thereof

A technology of humidity sensor and moisture-absorbing discoloration, which is applied in the direction of nanotechnology for sensing, fiber treatment, fiber type, etc., can solve the problems of difficult to realize the transformation of multiple colors, heavy metal residues, and affecting the safety of fiber use, and achieve high Practical application value, improvement of dispersibility, improvement of sensitivity and effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The invention provides a method for preparing a fiber-based humidity sensor based on hygroscopic discoloration, comprising the following steps:

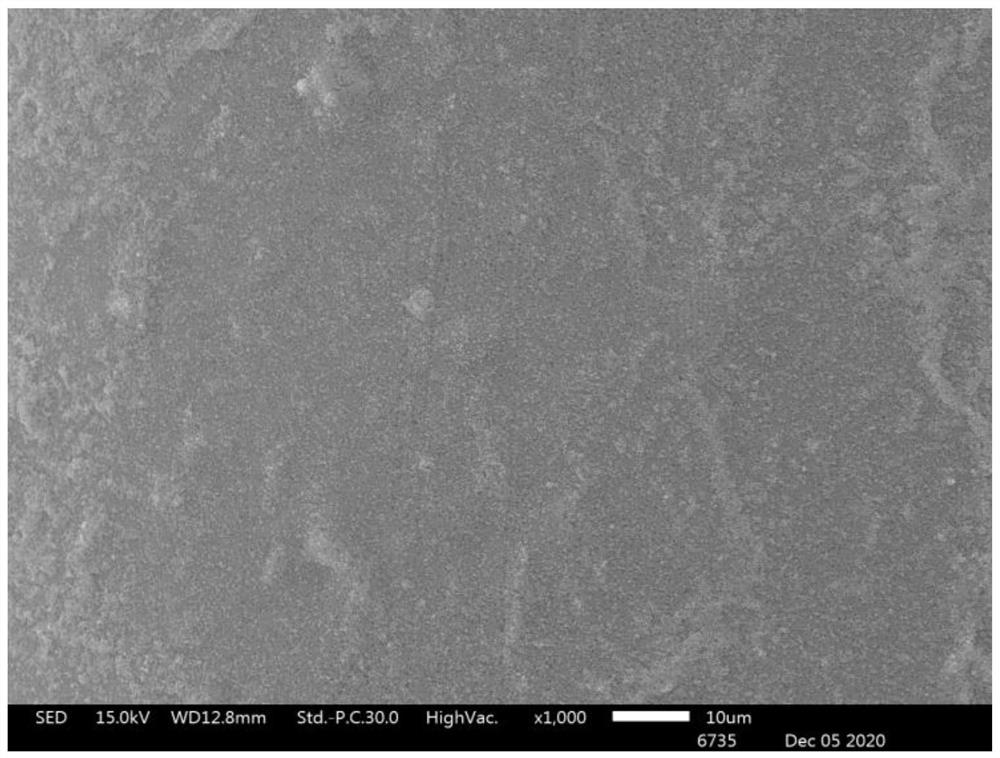

[0035] S1. Prepare silica nano-microspheres, and modify the silica nano-microspheres with an aminosilane coupling agent; after the reaction is sufficient, centrifuge, wash, and disperse to obtain modified silica nano-microspheres ball suspension;

[0036]S2. Prepare polyvinyl alcohol spinning solution and carbon nanotube solution with preset concentrations respectively, and then mix the polyvinyl alcohol spinning solution and the carbon nanotube solution to prepare polyvinyl alcohol / carbon nanotube spinning solution ; Add a predetermined amount of glutaraldehyde to the polyvinyl alcohol / carbon nanotube spinning solution, and after fully reacting, obtain a modified polyvinyl alcohol / carbon nanotube spinning solution;

[0037] S3, performing wet spinning on the modified polyvinyl alcohol / carbon nanotube spinning solution obtain...

Embodiment 1

[0048] This embodiment provides a method for preparing a fiber-based humidity sensor based on hygroscopic discoloration, including the following steps:

[0049] S1. Take 16mL of ethanol, 25mL of deionized water, and 2mL of ammonia water with a concentration of 25%, and add them to a single-necked round-bottomed flask respectively. After sealing with a glass stopper, adjust the magnetic stirring speed to 1000rpm and stir thoroughly; Pour tetraethyl ester into a beaker containing 45ml of ethanol and stir evenly; then drain the solution in the beaker into a round-bottomed flask with a glass rod, and adjust the magnetic stirring speed to 600rpm when the solution is completely reacted to milky white. Stir in a water bath at constant temperature for 8 hours, centrifuge and wash with ethanol three times after the reaction is complete, and disperse the obtained silica nanospheres in ethanol to obtain a suspension of silica nanospheres with a solid content of 1.5%.

[0050] Take 47mL o...

Embodiment 2~4

[0056] Embodiments 2 to 4 respectively provide a method for preparing a fiber-based humidity sensor based on hygroscopic discoloration. Compared with Embodiment 1, the difference is that the volume ratio of ammonia water and tetraethyl orthosilicate in step S1 and the reaction temperature, modified silica nanospheres with different particle diameters were obtained, and the preparation parameters and particle diameters of the modified silica nanospheres corresponding to each embodiment are shown in Table 1. The remaining steps of Embodiments 2-4 are consistent with Embodiment 1, and will not be repeated here.

[0057] The volume ratio of ammonia water and tetraethylorthosilicate and the particle size of the modified silica nanospheres prepared therein in Table 1 Examples 2 to 4

[0058]

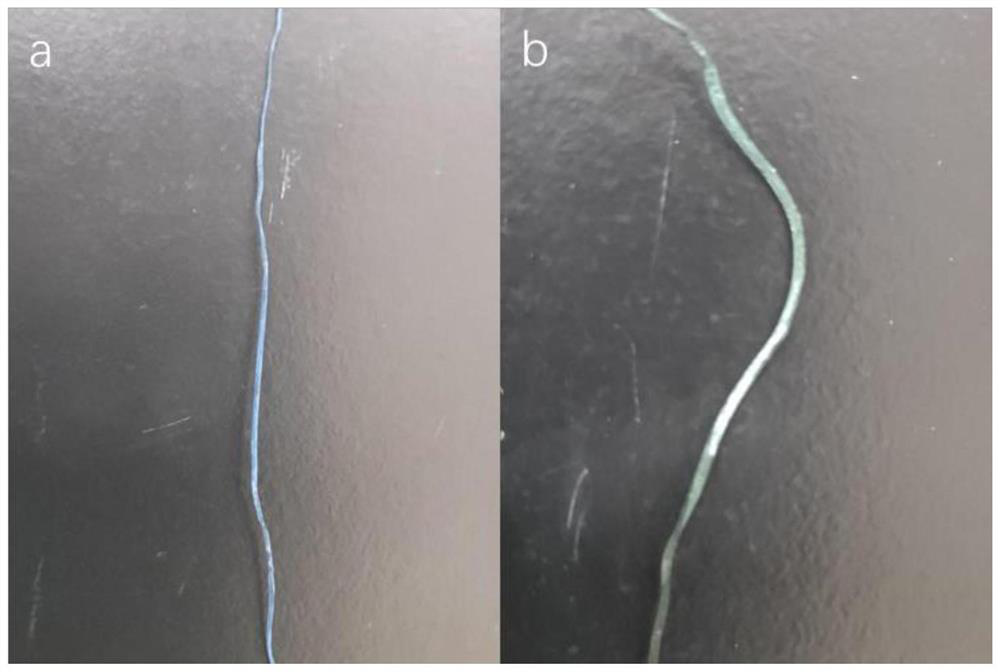

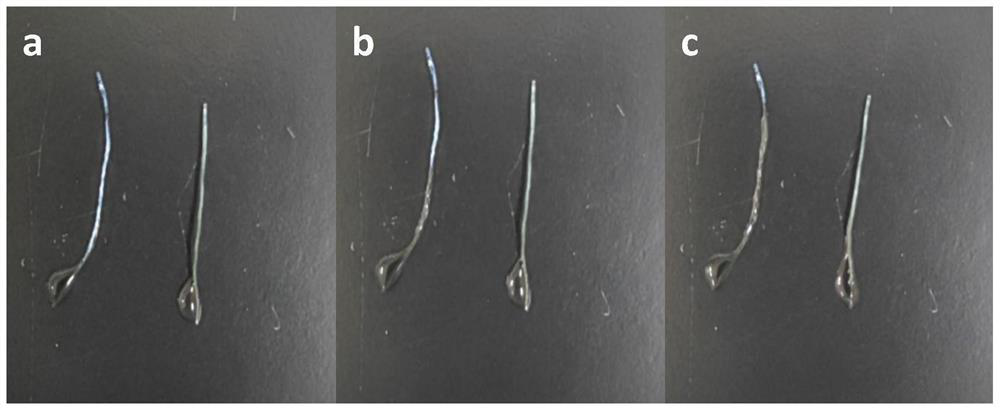

[0059] Wherein, the fiber-based humidity sensor based on hygroscopic discoloration prepared in embodiment 1 and embodiment 2 is respectively as follows figure 2 In a, b shown. Depend on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com