Konjac glucomannan film mask filter element and preparation method thereof

A technology of konjac glucomannan and glucomannan membrane, which is applied in the field of sanitary products, can solve the problems of low filtering effect and single use, and achieve the effect of inhibiting the growth of bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

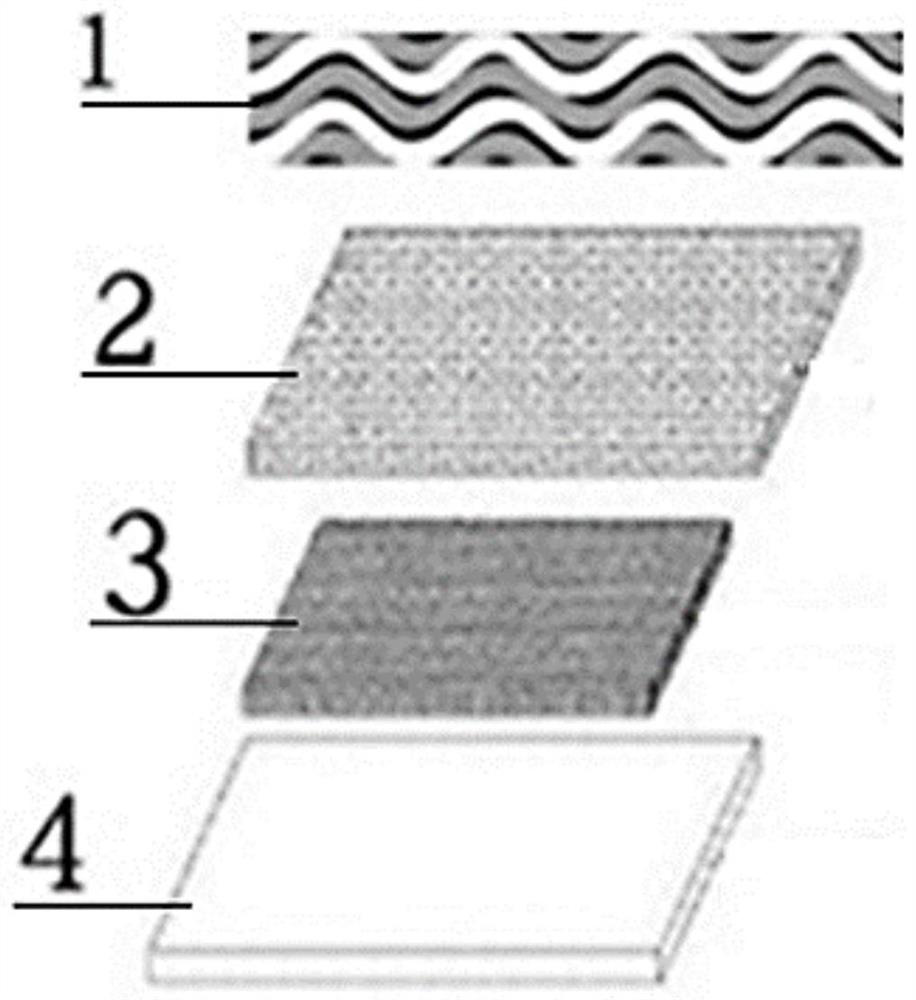

[0041] Wherein, a kind of preparation method of konjac glucomannan membrane mask filter element, based on above-mentioned konjac glucomannan membrane mask filter element, comprises the following steps,

[0042] To prepare the glucomannan paper fiber wave film layer 1, add 3.1 to 3.3 parts of paper fiber to 95 to 97 parts of pure water and stir evenly, then add 0.48 to 0.50 parts of anhydrous sodium carbonate and anhydrous sodium carbonate After dissolving, add 1 to 2 parts of konjac gum, stir with a magnetic stirrer at 300rpm for 60 to 90 minutes to obtain a mixed solution; then spread the mixed solution on a glass plate and place it at room temperature for 10 to 20 hours, then place the glass plate on Heating in an induction cooker at a high temperature for 15 to 20 minutes to obtain a film, and then roll forming the film so that the cross section of the film is wavy to obtain a wavy film layer 1 of konjac glucomannan paper fiber with a thickness of 0.3 to 0.8 mm; wherein, Th...

Embodiment 1

[0055] according to figure 1 As shown, the present embodiment provides a kind of preparation method of konjac glucomannan membrane mask filter element, comprising the following steps:

[0056] To prepare glucomannan paper fiber wave film layer 1, add 3 parts of paper fiber to 96 parts of pure water and stir evenly, then add 0.48 parts of anhydrous sodium carbonate, after the anhydrous sodium carbonate dissolves, add 1 part of Konjac gum was stirred with a magnetic stirrer at 300rpm for 60 minutes to obtain a mixed solution; then the mixed solution was spread on a glass plate, placed at room temperature for 20 hours, and then the glass plate was placed in an induction cooker and heated at a high temperature for 20 minutes to obtain a film, and then the The film is rolled and formed so that the cross section of the film is wavy, and after being cooled, it is placed in the refrigerator to freeze to obtain a konjac glucomannan paper fiber wave film layer 1 with a thickness of 0.3m...

Embodiment 2

[0069] according to figure 1 As shown, the present embodiment provides a kind of preparation method of konjac glucomannan membrane mask filter element, comprising the following steps:

[0070] To prepare the glucomannan paper fiber wave film layer 1, add 3.2 parts of paper fibers to 96 parts of pure water and stir evenly, then add 0.48 parts of anhydrous sodium carbonate, after the anhydrous sodium carbonate dissolves, add 2 parts Konjac gum was stirred with a magnetic stirrer at 300rpm for 90min to obtain a mixed solution; then the mixed solution was spread on a glass plate and placed at room temperature for 15 hours, then the glass plate was placed in an induction cooker pot and heated at a high temperature for 15min to obtain a film, and then the The film is rolled and formed so that the cross section of the film is wavy, and after cooling, it is placed in the refrigerator to freeze, and the konjac glucomannan paper fiber wave film layer 1 with a thickness of 0.8mm is obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com