Confirmation method for efficiently and harmlessly degrading SF6 waste gas through dielectric barrier discharge

A technology of dielectric barrier discharge and SF6, which is applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of single research point, low energy efficiency of degradation, and has not yet reached the level of industrial application, and achieve scientific configuration and degradation The effect of high energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

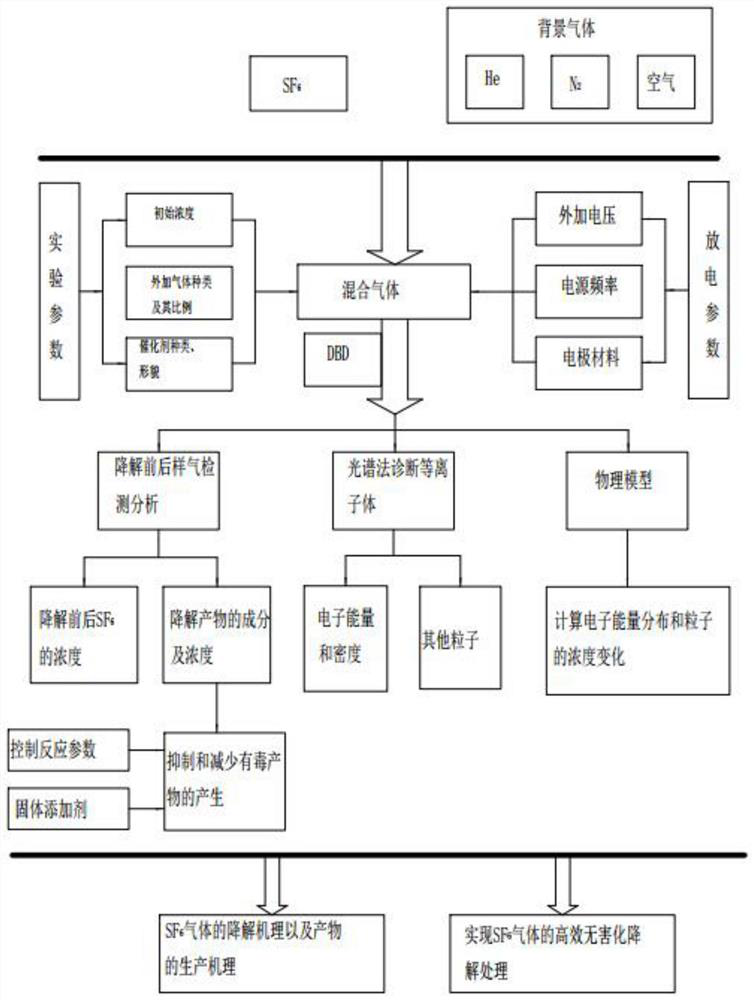

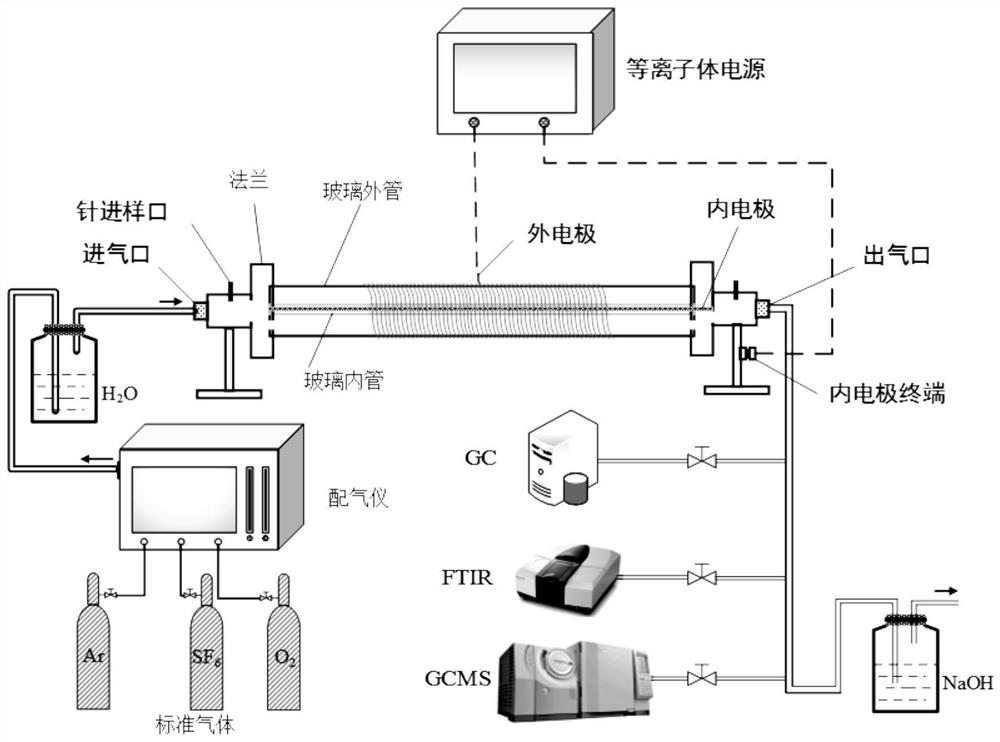

[0045] Embodiment 1: as Figure 1-Figure 2 As shown, the confirmation method for the efficient and harmless degradation of SF6 waste gas by dielectric barrier discharge includes the equipment used to degrade SF6 by dielectric barrier discharge 6 The experimental platform and analysis and detection system, dielectric barrier discharge degradation SF 6 The system includes a gas distribution system, a DBD reactor and a power supply system. The gas outlet of the gas distribution system is connected to the inlet of the DBD reactor. The DBD reactor is connected to a power system. The gas outlet of the DBD reactor is connected to the analysis and detection system. The detection system includes electrical parameter detection system, chemical parameter detection system and optical parameter detection system; analysis detection system includes oscilloscope, gas chromatograph (Gas Chromatograph, GC), Fourier Transform Infrared Spectrometer (Fourier Transform Infrared Spectrometer, FTIR),...

Embodiment 2

[0046] Embodiment 2: A method for confirming the efficient and harmless degradation of SF waste gas by dielectric barrier discharge, the method comprising the following steps:

[0047] (1) Build dielectric barrier discharge to degrade SF 6 experimental platform;

[0048] (2) Obtain dielectric barrier discharge to degrade SF 6 The experimental platform of the DBD reactor for the degradation of SF 6 Discharge parameters and experimental parameters, discharge parameters include applied voltage, external power supply and electrode materials, experimental parameters include initial concentration, applied gas type and its ratio, catalyst type, and morphology;

[0049] (3) Use the gas distribution system to perform SF on the DBD reactor 6 Gas and background gas distribution;

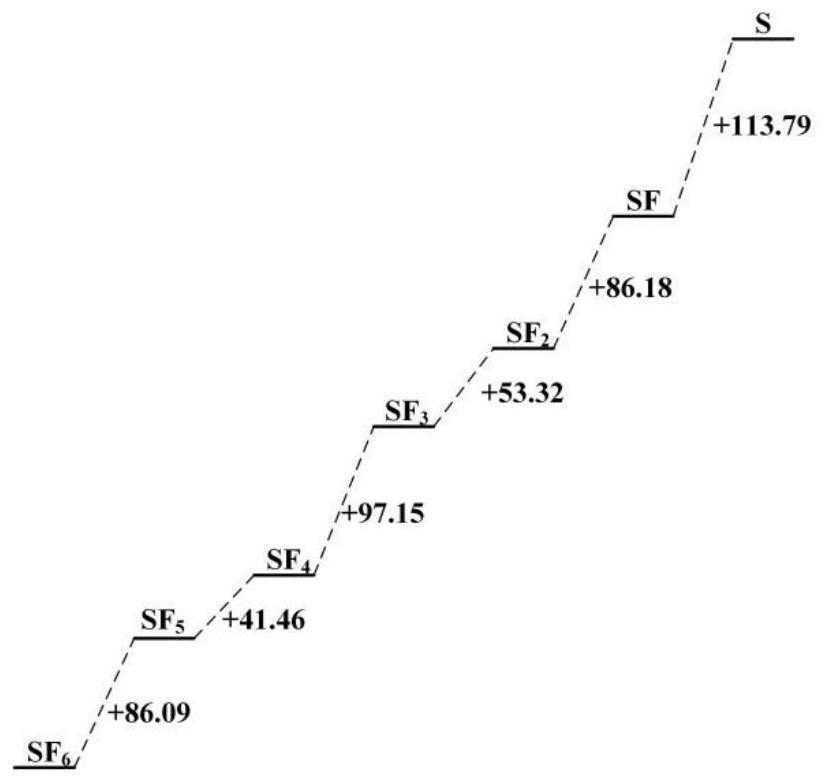

[0050] (4) Use the control variable method to change the SF that affects the dielectric barrier discharge decomposition 6 Various factors contribute to the SF 6 Forward decomposition experiment research, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com