Method of dust-free treatment of beryllium powder

A technology of dusting and inert liquid, applied in the field of beryllium powder dust-free treatment, can solve the problem of beryllium powder flying and other problems, achieve the effect of preventing oxidation, avoiding environmental pollution and health hazards, and the method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

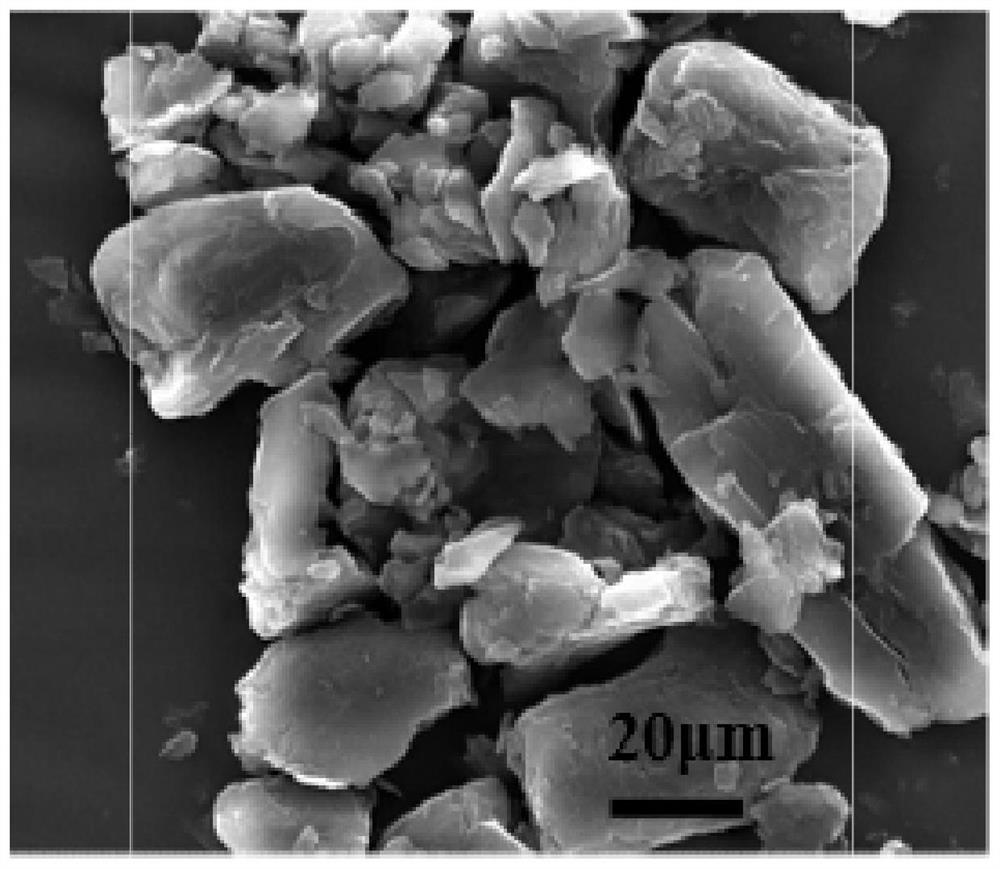

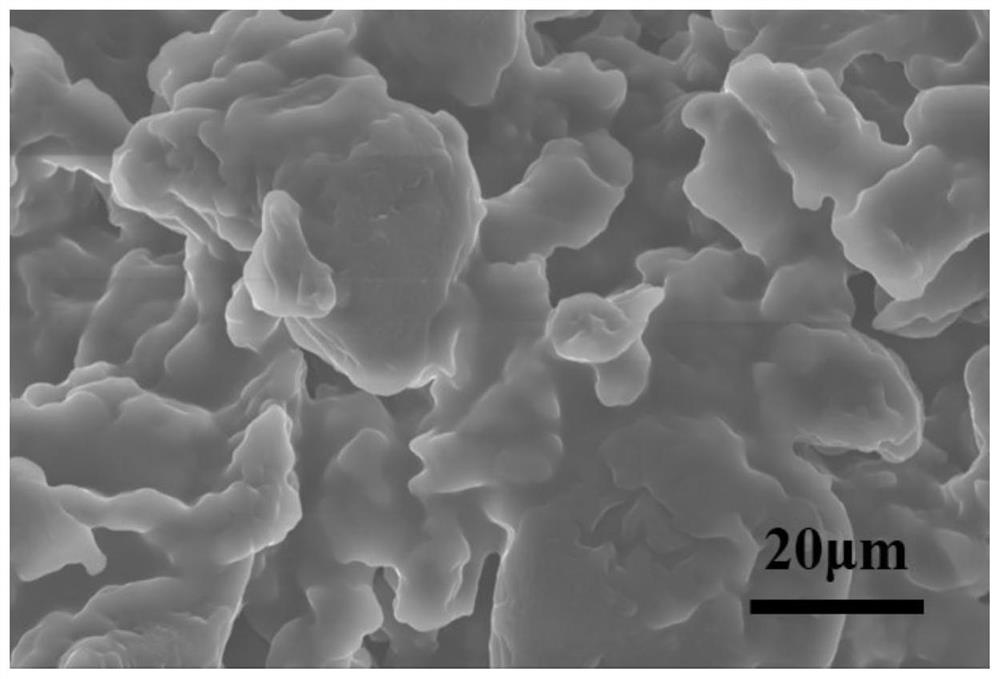

Image

Examples

specific Embodiment approach 1

[0017] DETAILED DESCRIPTION OF THE INVENTION The method of tonal dust treatment of the present embodiment is carried out in accordance with the following steps:

[0018] First, take the sealing package of beryllium powder and inert liquid;

[0019] The inert liquid is a liquid hydrocarbon that does not react with the beryium powder at room temperature and the boiling point is less than 400 ° C, or the decomposition temperature is less than 400 ° C, and the decomposition product is a volatile product at room temperature. Object;

[0020] Second, mix the hometown powder and inert liquid in step one, resulting in a mixture;

[0021] Third, the mixture obtained by the step two is allowed to stand. After standing, the 粉 powder is fully wet with the liquid and the inert liquid is completely covered with a powder;

[0022] This embodiment has the following beneficial effects:

[0023] The present embodiment provides a method of low-cost dust-free treatment, simple, easy to operate, and b...

specific Embodiment approach 2

[0024] DETAILED DESCRIPTION OF THE INVENTION Different: The present embodiment differs from the specific embodiment: a liquid hydrocarbon that does not react at room temperature and is less than 400 ° C at room temperature and a boiling point of less than 400 ° C for kerosene, n-elevenk, n-dodexecane , Positive decane, positive decades, n-octhane or positive hexadecane; no reaction at room temperature, the decomposition temperature is less than 400 ° C, and the decomposition product is a polymer of volatile product is polymer. Ethylene glycol-200, polyethylene glycol-300, polyethylene glycol-400, polypropylene glycol-400, etc.

specific Embodiment approach 3

[0025] BEST MODE FOR CARRYING OUT THE INVENTION The third embodiment is different from the body to the body: the volume of the inert liquid is 0.5-2 times the volume of the inert liquid (natural accumulation).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com