A method for dust-free treatment of beryllium powder

A technology of dusting and inert liquid, which is applied in the field of dust-free treatment of beryllium powder, can solve the problems of flying beryllium powder dust, etc., achieve the effect of preventing oxidation, simple method, and avoiding the contact between beryllium powder and air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

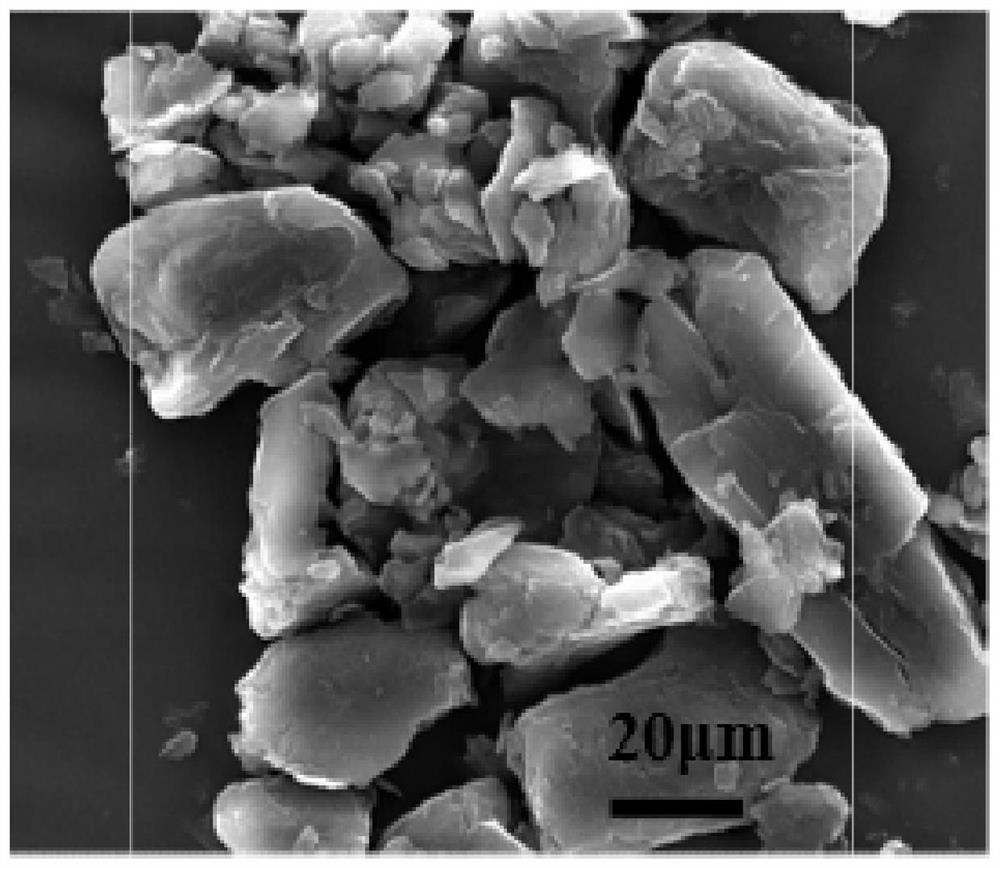

Image

Examples

specific Embodiment approach 1

[0017] Specific embodiment one: the method for dust-free treatment of beryllium powder in this embodiment is carried out according to the following steps:

[0018] 1. Take the beryllium powder and inert liquid in the sealed package;

[0019] The inert liquid is a liquid hydrocarbon that does not react with beryllium powder at room temperature and has a boiling point lower than 400°C, or a polymer that does not react with beryllium powder at room temperature, whose decomposition temperature is lower than 400°C, and whose decomposition products are all volatile products thing;

[0020] 2. Mix the beryllium powder and the inert liquid in the step 1 evenly to obtain the mixture;

[0021] 3. The mixture obtained in step 2 is left to stand for processing, and it is completed. After static treatment, the beryllium powder is fully wetted with the liquid and the inert liquid completely covers the beryllium powder;

[0022] This embodiment has the following beneficial effects:

[00...

specific Embodiment approach 2

[0024] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the liquid hydrocarbons described in step 1 that do not react with beryllium powder at room temperature and have a boiling point lower than 400°C are kerosene, n-undecane, and n-dodecane , n-tridecane, n-tetradecane, n-pentadecane or n-hexadecane; polymers that do not react with beryllium powder at room temperature, whose decomposition temperature is lower than 400°C, and whose decomposition products are all volatile products are poly Ethylene glycol-200, polyethylene glycol-300, polyethylene glycol-400, polypropylene glycol-400, etc.

specific Embodiment approach 3

[0025] Embodiment 3: This embodiment differs from Embodiment 1 or 2 in that: the volume of the inert liquid described in Step 1 is 0.5-2 times the volume of beryllium powder (natural accumulation).

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com