Method for preparing high-quality graphene through double-pulse electrochemical technology

A graphene, high-quality technology, applied in the field of materials, which can solve problems such as difficulty in complete removal, troublesome removal of electrolyte and impurity ions, and difficulty in removing anion and cation impurities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

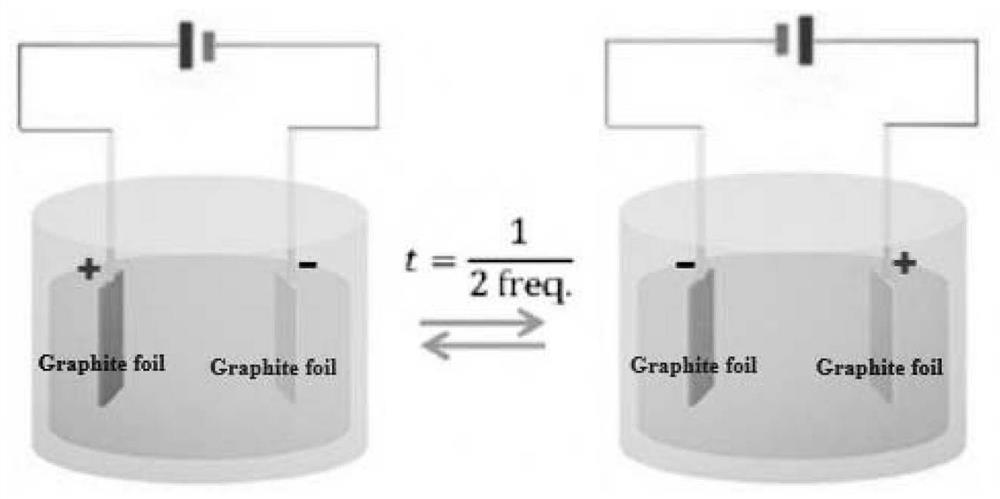

[0040] A method for preparing high-quality graphene by double-pulse electrochemical technology, comprising the following steps:

[0041] a) Select a double-pulse power supply system (that is, double-pulse power supply) to form an AC power supply that can switch between positive and negative poles in real time, and the control frequency is 0.01Hz;

[0042] b) Choose a graphite plate with a thickness of 4 μm and a size of 10cm×10cm as the anode graphite plate and the cathode graphite plate, and use the anode graphite plate and the cathode graphite plate as a group to connect 3 groups in parallel in turn, each group of anode graphite plate and cathode graphite plate The rooms are arranged face to face, and the distance is kept at 2cm;

[0043] c) Select an appropriate amount of 0.5M tetramethylammonium bisulfate electrolyte (the solvent is double-distilled water), keep the cathode graphite plate and the anode graphite plate soaked in the electrolyte for 3cm, then turn on the doub...

Embodiment 2

[0046] A method for preparing high-quality graphene by double-pulse electrochemical technology, comprising the following steps:

[0047] a) Select a dual-pulse power supply system to form an AC power supply that can be switched immediately between positive and negative poles, and the control frequency is 0.1Hz;

[0048] b) Choose a graphite plate with a thickness of 8 μm and a size of 10cm×10cm as the anode graphite plate and the cathode graphite plate, and use the anode graphite plate and the cathode graphite plate as a group to connect 8 groups in parallel in turn, each group of anode graphite plate and cathode graphite plate The rooms are arranged face to face, and the distance is kept at 1.5cm;

[0049] c) Select an appropriate amount of 0.1M tetramethylammonium bisulfate electrolyte (the solvent is double-distilled water), keep the cathode graphite plate and the anode graphite plate soaked in the electrolyte for 4cm, then turn on the double pulse power supply, keep the vo...

Embodiment 3

[0052] A method for preparing high-quality graphene by double-pulse electrochemical technology, comprising the following steps:

[0053] a) Select a dual-pulse power supply system to form an AC power supply that can be switched immediately between positive and negative poles, and the control frequency is 10Hz;

[0054] b) Choose a graphite plate with a thickness of 6 μm and a size of 10cm×10cm as the anode graphite plate and the cathode graphite plate, and use the anode graphite plate and the cathode graphite plate as a group to connect 5 groups in parallel in turn, each group of anode graphite plate and cathode graphite plate The rooms are arranged face to face, and the distance is kept at 2cm;

[0055] c) Select an appropriate amount of 0.5M tetramethylammonium bisulfate electrolyte (the solvent is double-distilled water), keep the cathode graphite plate and the anode graphite plate soaked in the electrolyte for 5cm, then turn on the double pulse power supply, keep the volta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com