Treatment method of thallium-containing wastewater

A treatment method and wastewater technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of insufficient utilization of active sites, limited adsorption capacity, regeneration Ineffective and other problems, to achieve the effect of good renewability and recyclability, low cost, and easy large-scale promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

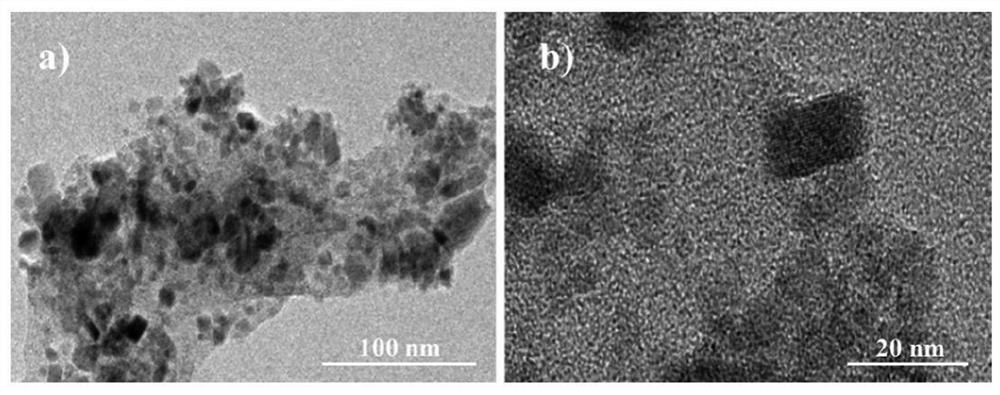

[0054] See attached Figure 1~14 , This embodiment is to treat a sample of thallium-containing industrial wastewater from a certain enterprise, so as to test and verify the performance of the present invention and the material of the magnetic adsorbent, such as recyclability, removal rate, and removal speed. The adsorption experiment conditions were that the initial concentration of Tl(I) in water was 10 mg / L, the pH of the solution was 7.0, and rGO-Fe 3 o 4 @TiO 2 The amount of magnetic adsorbent is 50mg, the adsorption time is 0.5h, and the temperature is 25±1°C.

[0055] The treatment method of the thallium-containing wastewater provided by the present embodiment comprises the following steps:

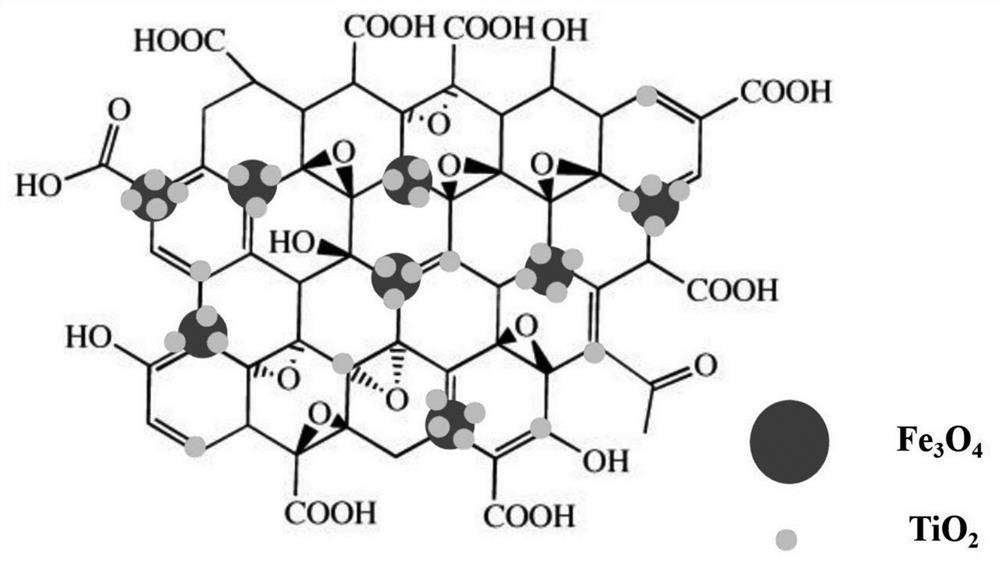

[0056] A) Preparation of magnetic adsorbent rGO-Fe, respectively 3 o 4 @TiO 2 (reduced graphene oxide nanocomposite material), persulfate PS (specifically select potassium persulfate in this embodiment);

[0057] B) Obtain a sample of thallium-containing wastewater, determine...

Embodiment 2

[0089] The treatment method of the thallium-containing wastewater provided by the embodiment of the present invention is basically the same as that of Example 1, except that the initial concentration of Tl in the thallium-containing wastewater in this embodiment is 56 µg / L, the pH is 5.6, and the rGO -Fe 3 o 4 @TiO 2 The dosage was 0.1g / L, and the dosage of PS was 10mM. Samples were taken at 5, 10, 15, 20, and 30 minutes respectively to analyze the treatment performance. The test results showed that at 10 minutes, rGO-Fe 3 o 4 @TiO 2 The removal efficiency of Tl in wastewater is 96%. The material can be quickly separated by an external magnetic field, which shows that the material can quickly and efficiently remove Tl in wastewater, and is easy to separate. It can be used for the treatment of thallium-containing wastewater and the emergency treatment of thallium. Disposal.

[0090] The magnetic adsorbent rGO-Fe 3 o 4 @TiO 2 (reduced graphene oxide nanocomposite materia...

Embodiment 3

[0095] The treatment method of the thallium-containing wastewater provided by the embodiment of the present invention is basically the same as that of Examples 1 and 2, except that:

[0096] This embodiment deals with 1m 3 Thallium-containing wastewater, the pH of which is 7, the initial concentration of Tl in the wastewater is 56 µg / L, the calculated rGO-Fe 3 o 4 @TiO 2 The dosage is 150g, and the dosage of PS is 240g; after testing, within 10min, rGO-Fe 3 o 4 @TiO 2 The removal efficiency of Tl in wastewater was 96%, within 30min, rGO-Fe 3 o 4 @TiO 2 The removal efficiency of Tl in wastewater is 98wt%, and the concentration of Tl in the treated water is 1.12µg / L, meeting the "Discharge Standard for Thallium Pollutants in Industrial Wastewater" (DB44 / 1989-2017).

[0097] The magnetic adsorbent rGO-Fe 3 o 4 @TiO 2 The preparation method, it specifically comprises the steps:

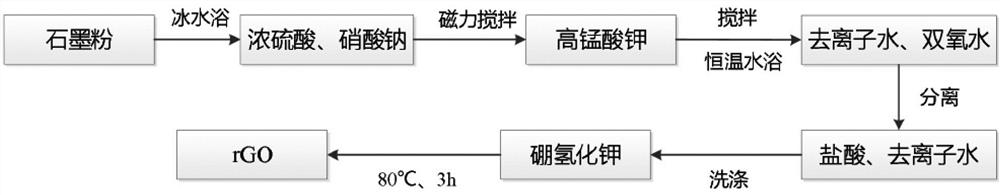

[0098] 1. Preparation of rGO

[0099] The reduced graphene oxide rGO nanosheets were syn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com