A kind of adsorbent for removing polar molecules in light hydrocarbon stream and its preparation and regeneration method

A polar molecule and adsorbent technology, applied in the fields of adsorbent and its preparation and regeneration, can solve the problems of increasing adsorbent preparation process, no more mention of important indicators of adsorbent adsorption capacity, low adsorption heat adsorption capacity, etc. , to achieve the effect of improving selectivity and adsorption capacity, reasonable surface charge distribution, and simple regeneration method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

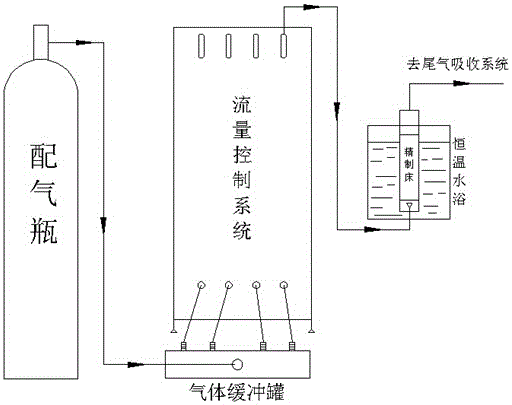

Method used

Image

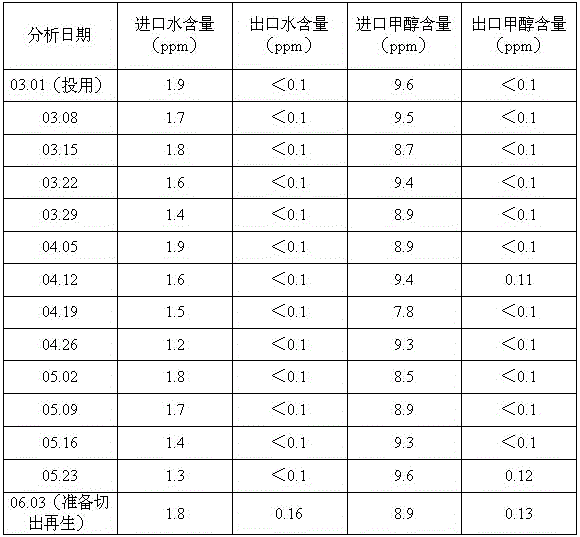

Examples

Embodiment 1

[0038] (1) Weigh 30g of Y-type molecular sieve raw powder with a molecular sieve particle size of 0.1 μm and activated alumina (δ-Al 2 o 3 ) 20g in a beaker, slowly add 2.5g of ethylenediamine pore expander into the beaker, place the beaker in a constant temperature water bath with stirring, adjust the temperature to 30°C, stir and react for 2 hours, then dry it for later use, and obtain the adsorbent Masterbatch, the specific surface area of the adsorbent masterbatch is 210m 2 / g;

[0039] (2) Put 50g of the adsorbent masterbatch prepared in the above step (1) into the ion exchange column, slowly add 10% ion exchange solution dropwise from the top of the exchange column, and the ion exchange solution is composed of 7% KNO 3 and 3% lanthanum nitrate, the dropping rate is 50ml / h, after 12h, the adsorbent is taken out and dried; add 0.4% water glass solution to the dried adsorbent masterbatch, and place it in a rolling ball machine for rolling Ball granulation, drying the s...

Embodiment 2

[0042] (1) Weigh 20g of Y-type molecular sieve raw powder with a molecular sieve particle size of 0.5 μm and activated alumina (δ-Al 2 o 3 ) 30g in a beaker, slowly add 2.5g of triethylamine pore-enlarging agent into the beaker, place the beaker in a constant temperature water bath with stirring, adjust the temperature to 20°C, stir for 2 hours and then dry it for later use to obtain the adsorbent Masterbatch, the specific surface area of the adsorbent masterbatch is 205m 2 / g;

[0043] (2) Put 50g of the adsorbent masterbatch prepared in the above step (1) into the ion exchange column, slowly add 6% ion exchange solution dropwise from the top of the exchange column, and the ion exchange solution is composed of 3% KNO 3 and 3% lanthanum nitrate, the dropping rate is 50ml / h, after 4 hours, the adsorbent is taken out and dried; add 0.2% water glass solution to the dried adsorbent masterbatch, and place it in a rolling ball machine for rolling The pellets were granulated, an...

Embodiment 3

[0046] (1) Weigh 30g of Y-type molecular sieve raw powder with a molecular sieve particle size of 1 μm and activated alumina (δ-Al 2 o 3 ) 20g in a beaker, slowly add 2.5g of N,N-dimethyldodecylamine pore expander to the beaker, place the beaker in a constant temperature water bath with stirring, adjust the temperature to 30°C, and stir for 2h After drying for subsequent use, the adsorbent masterbatch is obtained, and the specific surface area of the adsorbent masterbatch is 240m 2 / g;

[0047] (2) Put 50g of the adsorbent masterbatch prepared in the above step (1) into the ion exchange column, slowly add 10% ion exchange solution dropwise from the top of the exchange column, and the ion exchange solution is composed of 7% KNO 3 and 3% lanthanum nitrate, the dropping rate is 50ml / h, after 12h, the adsorbent is taken out and dried; add 0.4% water glass solution to the dried adsorbent masterbatch, and place it in a rolling ball machine for rolling Ball granulation, drying o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com