A high-performance bulk aramid nanofiber aerogel and its preparation method and application

A technology of nanofibers and aramid fibers, which is applied in the field of high-strength bulk aramid nanofiber airgel and its preparation, and can solve the problems of viscous hydrogels not forming blocks, difficulty in industrialization, and long preparation cycle , to achieve the effects of porosity and density controllable, easy to be continuous, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] A first aspect of the present invention provides a preparation method of aramid nanofiber aerogel, the method comprising the following steps:

[0024] (1) Preparation of aramid nanofiber (ANF) colloidal dispersion;

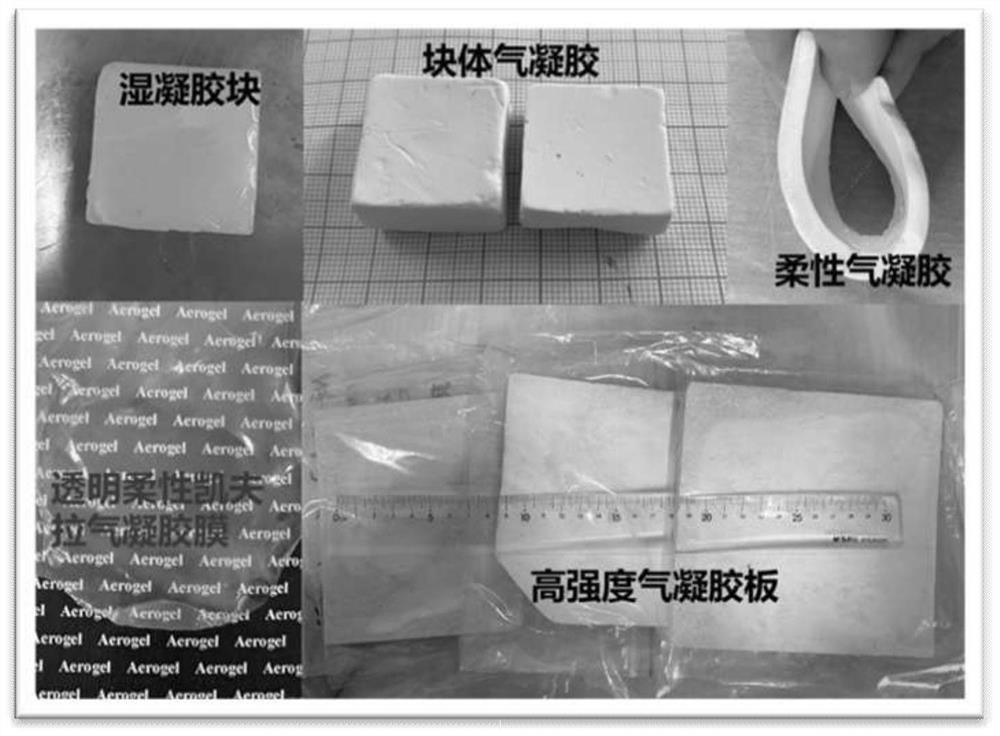

[0025] (2) using the ANF colloidal dispersion to prepare bulk ANF wet gel;

[0026] (3) Using the ANF wet gel to prepare ANF aerogel.

[0027] According to some preferred embodiments, in step (1), the mixing system of aramid fibers, organic solvent and alkali is subjected to stirring treatment to make the aramid fibers uniformly dispersed to obtain an aramid fiber dispersion; Adding proton donors and / or ionic reaction assistants to the fiber dispersion liquid to catalyze the reaction rate of nanometerization, and stirring to obtain the ANF colloidal dispersion liquid;

[0028] In the present invention, unless otherwise specified, the aramid fiber refers to the macro-aramid fiber with a diameter of micrometer order or larger. For example, the aramid fiber...

Embodiment 1

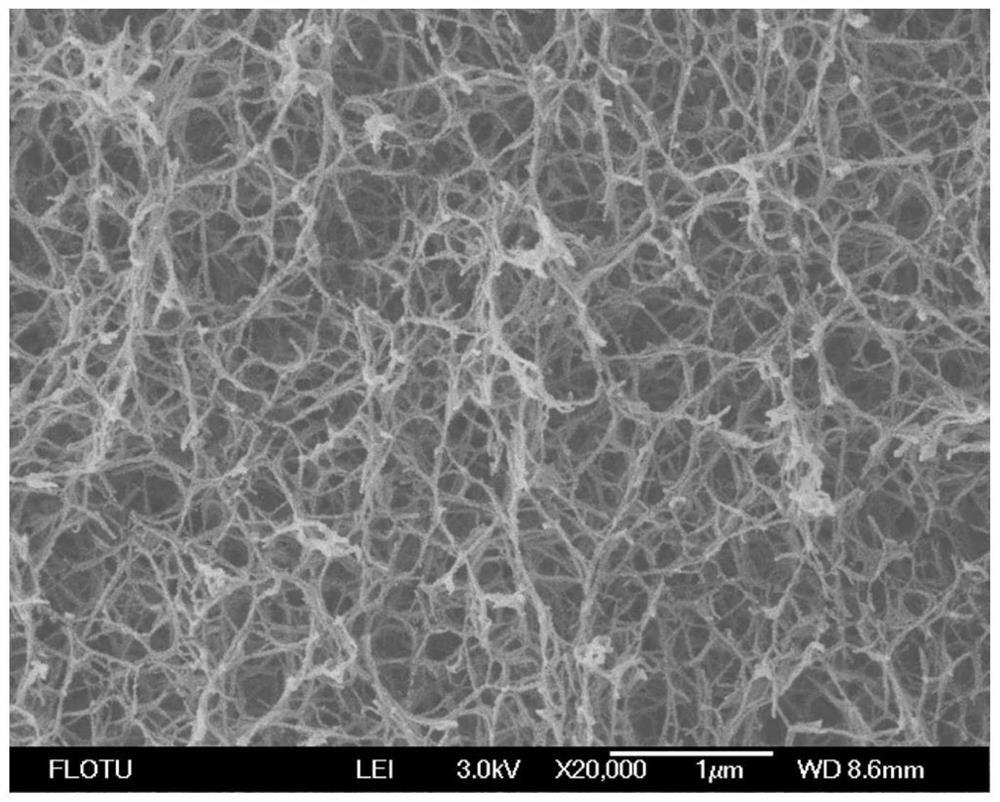

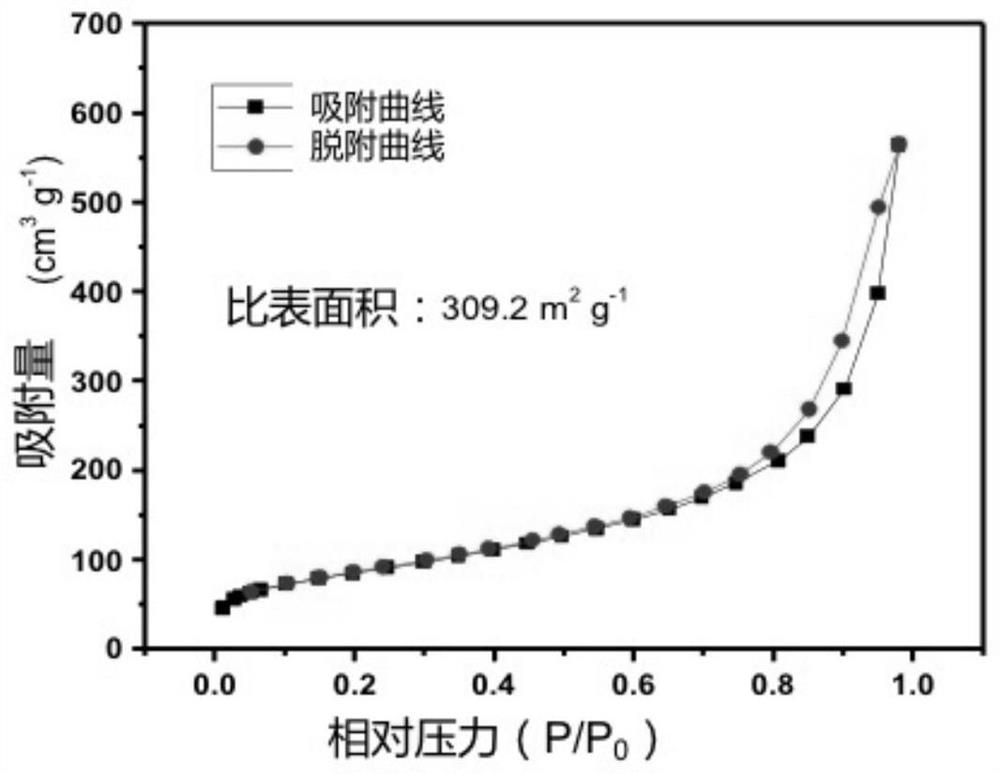

[0062] (1) Preparation of ANF colloidal dispersion: 6g Kevlar chopped fibers (about 12-20 microns in diameter, 6 mm in length, purchased from DuPont), 600 ml dimethyl sulfoxide (DMSO), and 1 g KOH were added to the reaction vessel, and the Under the environment of normal temperature (25°C), the high shear disperser rotates at 4000rpm and stirs for 5min to obtain a light yellow uniform dispersion of macro aramid fibers. To the dispersion, add a solution of 18g deionized water and 2g KOH at one time, A mixed solution was obtained, the rotating speed was adjusted to 5000 rpm, and the stirring reaction was continued for 1 h to obtain a black-red uniform transparent aramid nanofiber colloidal dispersion.

[0063] (2) Preparation of ANF wet gel block: Pour the ANF colloidal dispersion obtained in step (1) into a custom-shaped mold, place the mold in a vacuum box, and let stand for 2-10 minutes to remove foam; add water , promote the phase transition of the dispersion, age at room te...

Embodiment 2

[0066] (1) Preparation of ANF colloidal dispersion: 12g of Kevlar chopped fibers used in Example 1, 600ml of dimethyl sulfoxide (DMSO), 2g of KOH, and 2g of potassium ethoxide were added to the reaction vessel. Under the rotating speed of 4000rpm, the shear disperser was stirred for 5 minutes to obtain a light yellow uniform dispersion of macro aramid fibers; 18g of deionized water and 4g of KOH were added to the dispersion, and the reaction was continued for 0.5h; then 10ml of ethanol was added , 1g potassium ethoxylate, adjust the rotating speed to 3000rpm and continue to stir for 2h to obtain a black-red uniform transparent aramid nanofiber colloidal dispersion.

[0067] (2) Preparation of ANF wet gel block: the same procedure as in Example 1.

[0068] (3) Preparation of ANF aerogel block: the same steps as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com