Sapphire cutting fluid and preparation method thereof

A cutting fluid and sapphire technology, applied in the petroleum industry, lubricating compositions, etc., can solve problems such as broken wires, substandard flatness, and short life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

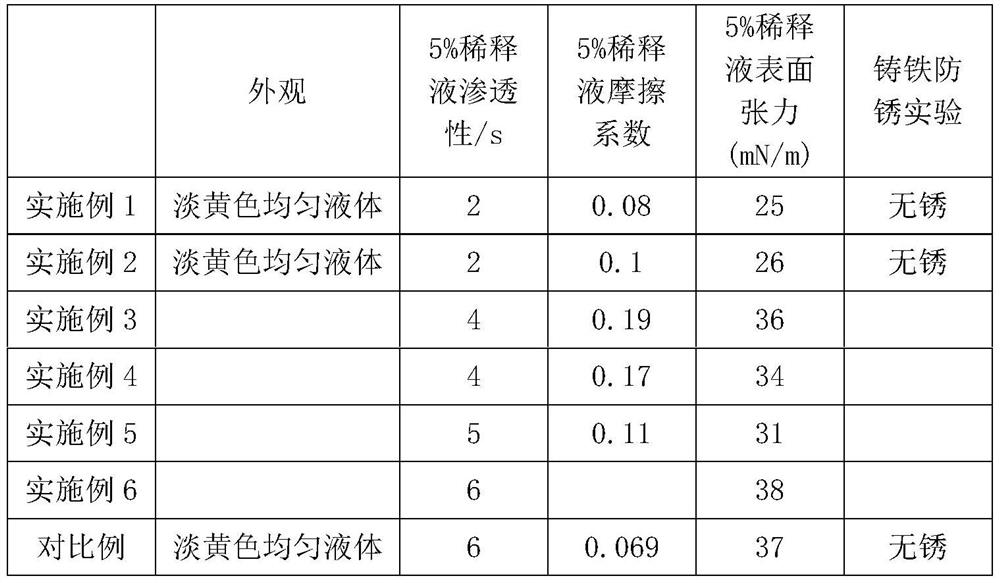

Examples

Embodiment 1

[0090] Embodiment 1 of the present invention provides a kind of sapphire cutting fluid, the preparation raw material of described cutting fluid comprises, by weight, 44 parts of small molecular organic solvents, 20 parts of water, 5 parts of extreme pressure lubricants, 2 parts of dispersants , 3 parts of wetting defoamer, 10 parts of wetting agent, 16 parts of emulsifier, 0.5 part of rust inhibitor, 0.5 part of bactericide, 1 part of alkaline buffer;

[0091] The small molecule organic solvent is a small molecule alcohol solvent and a small molecule alcohol ether solvent; the weight ratio of the small molecule alcohol solvent to the small molecule alcohol ether solvent is 1.1:1; the small molecule alcohol solvent is Propylene glycol; The small molecule alcohol ether solvent is ethylene glycol monomethyl ether (CAS No.: 109-86-4);

[0092] Described water is distilled water;

[0093] The extreme pressure lubricant triethanolamine extreme pressure lubricant; the triethanolamin...

Embodiment 2

[0103] Embodiment 2 of the present invention provides a kind of sapphire cutting fluid, the preparation raw material of described cutting fluid comprises, by weight, 45 parts of small molecular organic solvents, 15 parts of water, 8 parts of extreme pressure lubricants, 2 parts of dispersants , 4 parts of wetting defoamer, 7 parts of wetting agent, 17 parts of emulsifier, 0.5 part of rust inhibitor, 0.5 part of bactericide, 1 part of alkaline buffer;

[0104] The small molecule organic solvent is a small molecule alcohol solvent and a small molecule alcohol ether solvent; the weight ratio of the small molecule alcohol solvent to the small molecule alcohol ether solvent is 0.8:1; the small molecule alcohol solvent is Diethylene glycol (CAS No.: 111-46-6); the small molecule alcohol ether solvent is ethylene glycol monoethyl ether (CAS No.: 110-80-5);

[0105] Described water is distilled water;

[0106] The extreme pressure lubricant is triethanolamine extreme pressure lubrica...

Embodiment 3

[0116] Embodiment 3 of the present invention provides a sapphire cutting fluid, and its specific implementation method is the same as that of Embodiment 1, except that there is no small molecule alcohol ether solvent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com