Carbon nitride modified Janus acid-resistant nanofiltration membrane as well as preparation method and application thereof

A carbon nitride and nanofiltration membrane technology, which is applied in chemical instruments and methods, membranes, membrane technology, etc., can solve problems such as low reaction rate and long reaction time, and achieve simple preparation methods, improved anti-pollution performance, and wide application range wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The invention discloses a preparation method of a carbon nitride modified Janus acid-resistant nanofiltration membrane, comprising:

[0023] S1: Immerse the ultrafiltration base membrane in the prepared aqueous solution for reaction, and obtain the ultrafiltration base membrane 1 after drying; wherein, the aqueous phase solution includes the aqueous phase monomer A, the acid-binding agent, the two-dimensional nanomaterial B and Surfactant;

[0024] S2: immerse ultrafiltration base membrane 1 into the oil phase solution to react to obtain ultrafiltration base membrane 2;

[0025] S3: Ultrafiltration basement membrane 3 is obtained after ultrafiltration basement membrane 2 heat treatment;

[0026] S4: Treating the ultrafiltration base membrane with three acids to obtain a carbon nitride-modified Janus acid-resistant nanofiltration membrane.

[0027] In some embodiments of the present invention, in step S1, the concentration of the aqueous phase monomer A in the aqueous ...

Embodiment 1

[0068] Prepare 100ml of aqueous solution: weigh 1g of polyethyleneimine with a molecular weight of 1800, 0.05g of sodium dodecylsulfonate, 0.175g of C 3 N 4 Powder, add deionized water to 100ml, fully disperse and stir for 3 hours;

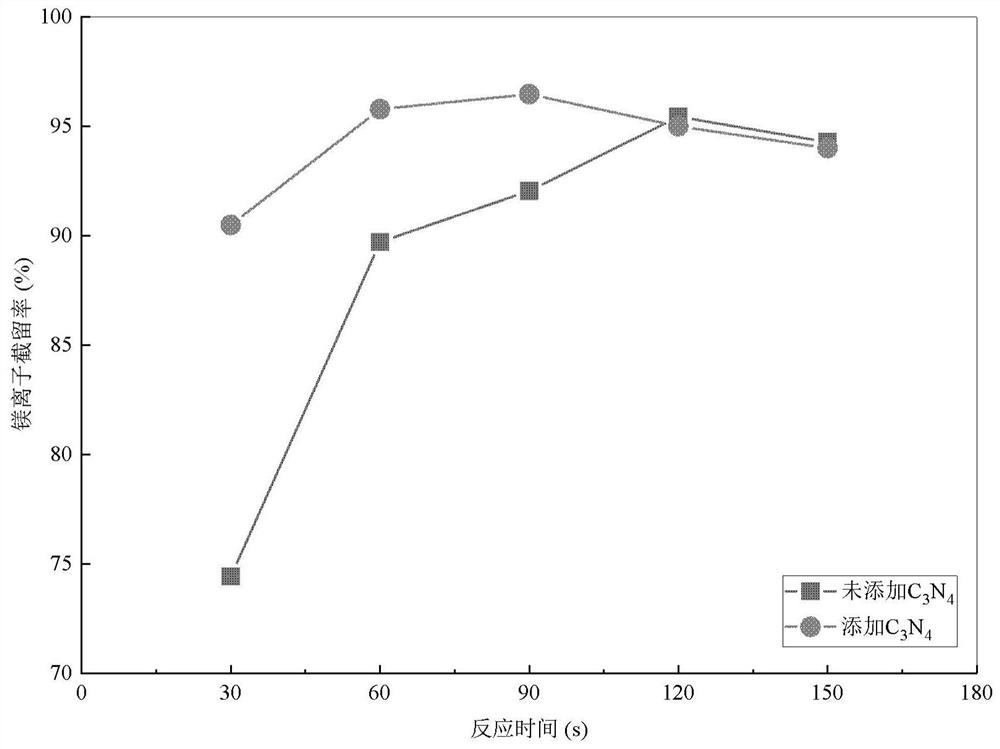

[0069] Prepare 100ml of oil phase solution: weigh 0.015g of cyanuric chloride, dissolve it in 100ml of n-hexane solvent, and stir thoroughly for 3 hours; soak the polyethersulfone ultrafiltration membrane soaked in deionized water in the water phase solution first 5min, take it out and dry it in the air, immerse it in the oil phase solution at 25°C for 90s, heat it at 70°C for 5min, wash it with deionized water, and then use 15wt% citric acid in a water bath at 50°C Soak for 10 minutes, and then rinse again with deionized water.

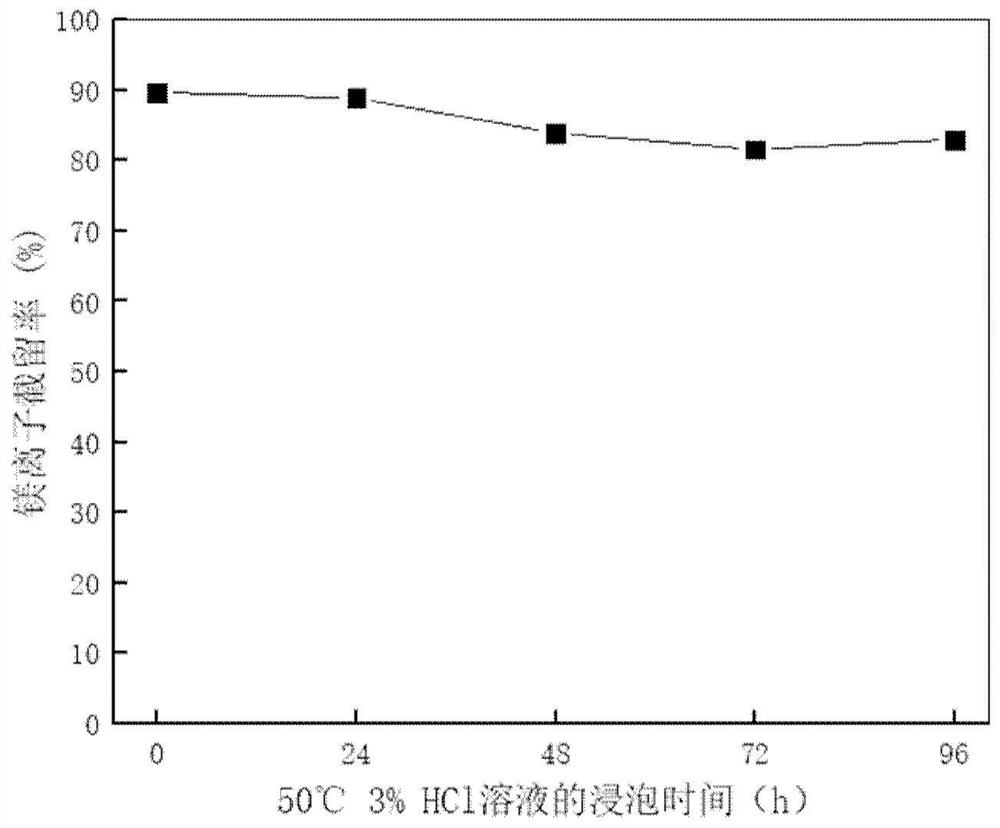

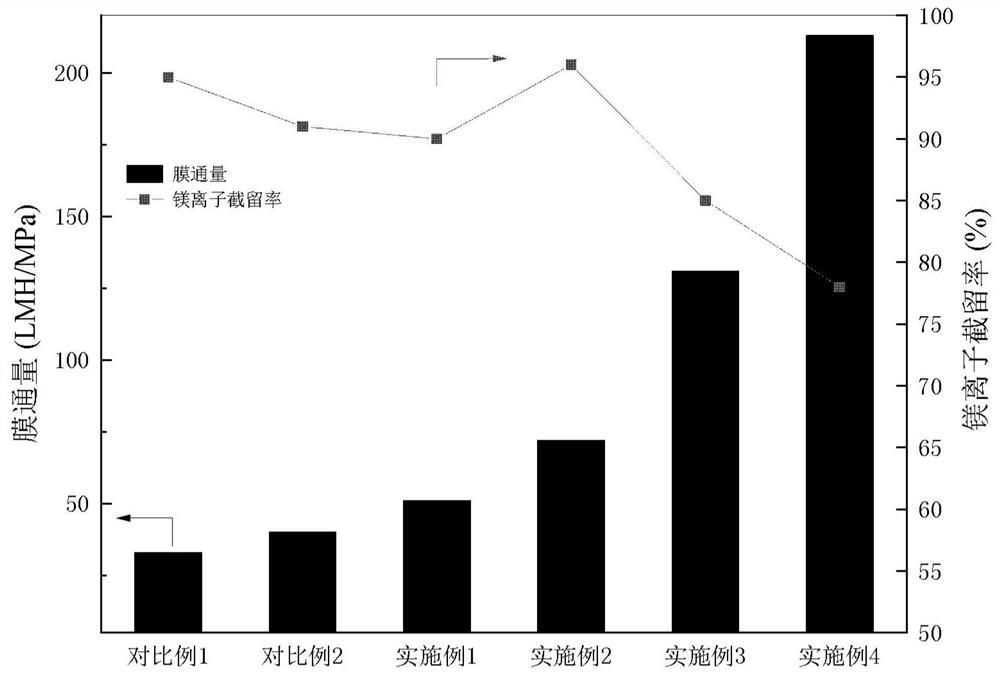

[0070] At normal temperature, measure its flux, it is 51LMH / MPa, measure its to 2g / LMgCl 2 With a rejection rate of 96%, the high-throughput C 3 N 4 The modified Janus acid-resistant nanofiltration membrane was soak...

Embodiment 2

[0072] Prepare 100ml of aqueous phase solution: weigh 1g of polyethyleneimine with a molecular weight of 1800, 0.05g of sodium dodecylsulfonate, and 0.105g of C 3 N 4 Powder, add deionized water to 100ml, fully disperse and stir for 3 hours;

[0073] Prepare 100ml of oil phase solution: weigh 0.015g of cyanuric chloride, dissolve it in 100ml of n-hexane solvent, and stir thoroughly for 3 hours; soak the polyethersulfone ultrafiltration membrane soaked in deionized water in the water phase solution first 5min, take it out and dry it in the air, immerse it in the oil phase solution at 25°C for 120s, heat it at 70°C for 5min, wash it with deionized water, and then use 15wt% citric acid in a water bath at 50°C Soak for 10 minutes, and then rinse again with deionized water.

[0074] Measure its flux at normal temperature, it is 72LMH / MPa, and measure it to 2g / LMgCl 2 The rejection rate is 96%, which is 2g / LNa 2 SO 4 The rejection of the solution was 24%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com