A comprehensive disposal system for resource utilization of chlor-alkali industrial salt mud

A technology of chlor-alkali industry and disposal system, which is applied in the field of comprehensive disposal system of salt mud resources in chlor-alkali industry, can solve the problems existing in the test stage, no engineering examples, difficult economic benefits, etc., to reduce NaOH consumption and corrosion The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below with reference to the accompanying drawings and embodiments.

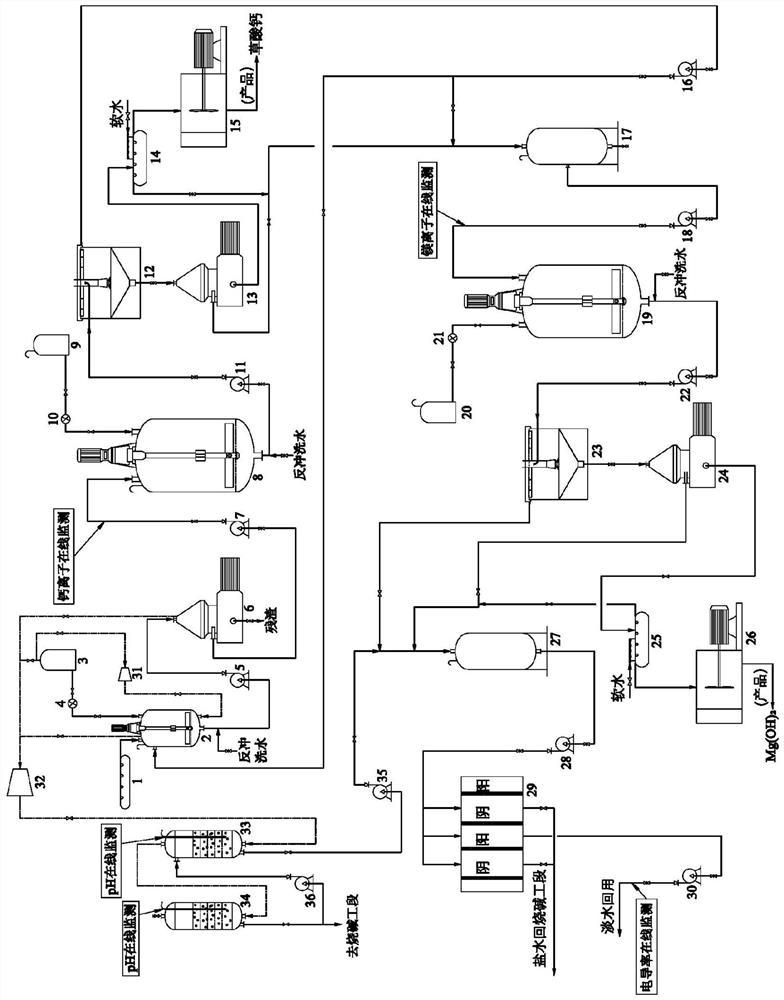

[0031] refer to figure 1 , a chlor-alkali industrial salt mud resource comprehensive disposal system, including a pretreatment unit, a product recovery unit, and a wastewater and waste gas treatment and recovery unit;

[0032] Described pretreatment unit: the chlor-alkali industrial salt sludge is sent into the first stirring reaction kettle 2 with 0.5 ton / h by belt conveyor / screw feeder 1, while the concentrated hydrochloric acid in the concentrated hydrochloric acid storage tank 3 is The first metering pump 4 is 1.2m 3 / h is sent into the first stirring reaction kettle 2 to react with the chlor-alkali industrial salt mud;

[0033] The reaction solution in the first stirring reaction kettle 2 is 5.0-5-5m by the first discharge pump 5. 3 / h is sent to the feed port of the first decanter centrifuge 6, the unreacted residue is discharged from the slag out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com