Novel coating for building wall surface as well as preparation method and application of novel coating

A new type of wall surface technology, applied in the field of building materials, can solve the problems of poor heat insulation and sound insulation effects, poor tensile strength of mortar, easy cracking, etc., achieve good thermal insulation and heat insulation performance, and good heat insulation effect , Improve the effect of tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

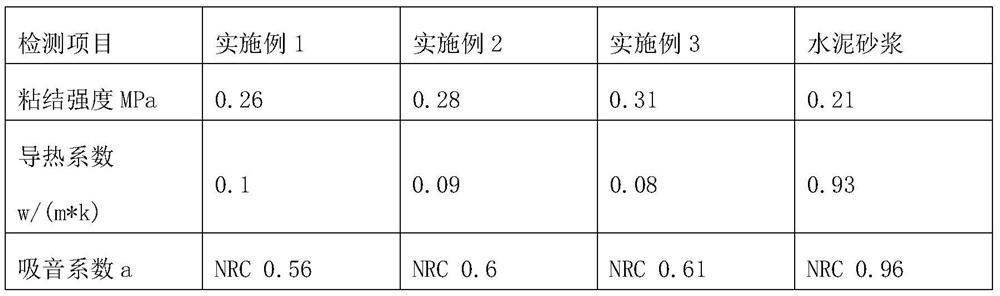

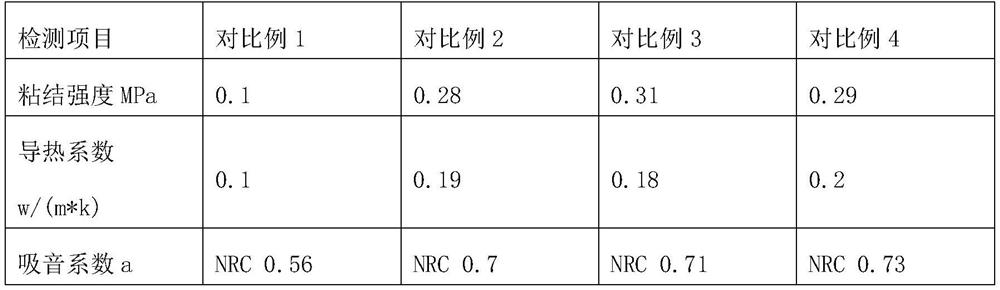

Examples

Embodiment 1

[0021] A new type of paint for building walls is composed of the following components calculated by mass percentage: 25% of silica fiber, 40% of expanded perlite micropowder, 20% of hollow glass microsphere, and 20% of sericite powder.

[0022] The silica fiber used is the quartz fiber chopped SJ104 of Henan Shenjiu Tianhang New Material Co., Ltd.; the expanded perlite micropowder is the expanded perlite micropowder of Shandong Yuancheng New Material Technology Co., Ltd.; the hollow glass microspheres It is HS20 from Zhengzhou Shenglaite Hollow Microsphere New Material Co., Ltd.; the sericite powder is CJ-A2 from Chuzhou Wanqiao Sericite Co., Ltd.

Embodiment 2

[0024] A new type of paint for building walls is composed of the following components calculated by mass percentage: 30% of silica fiber, 30% of expanded perlite micropowder, 10% of hollow glass microsphere, and 30% of sericite powder.

[0025] The silica fiber used is the alkali-free glass fiber chopped yarn from Hangzhou Gaoke Composite Materials Co., Ltd.; the expanded perlite powder is the superfine perlite powder specially used for filling in Yongxin Perlite Factory, Pingqiao District, Xinyang City; the hollow glass The microbeads are FS80001 glass microbeads from Dali Yishan Polishing Material Firm in Nanhai District, Foshan City; the sericite powder is 140 sericite powder from Chuzhou Zhulong Guangwei Sericite Powder Factory.

Embodiment 3

[0027] A new type of paint for building walls is composed of the following components calculated by mass percentage: 35% of silicon dioxide fiber, 50% of expanded perlite micropowder, 10% of hollow glass microsphere, and 20% of sericite powder.

[0028] The silica fiber used is chopped glass fiber from Guangzhou Haozhao Chemical Co., Ltd.; the expanded perlite powder is expanded perlite powder from Xinyang Xinyongwei Industrial Co., Ltd.; the hollow glass microspheres are from Hebei Runri Mineral Products Co., Ltd. The company's 60# glass microspheres; the sericite powder is the 800 mesh sericite powder of Guangdong Yongfeng Chemical Co., Ltd.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com