Preparation method of ferric carboxymaltose

A carboxyl maltose iron, carboxyl maltose technology, applied in the field of pharmaceutical chemical industry, can solve problems such as molecular weight control of carboxyl maltose iron, and achieve the effects of great practical significance, simple method and low technical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

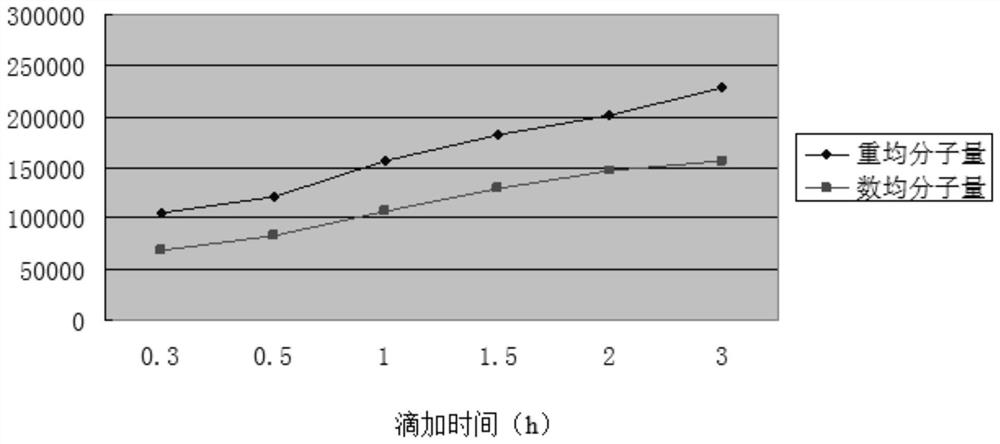

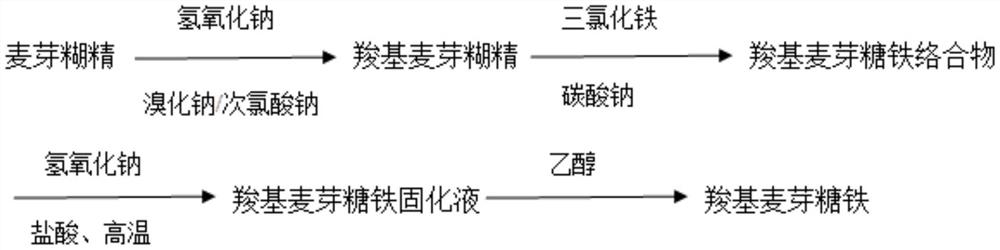

[0036] Maltodextrin 100g, add 200ml of water and stir to dissolve, add 1g of sodium bromide, add 30% sodium hydroxide solution to adjust the pH of the maltodextrin solution to 9.0-11.0, control the temperature at 25-40°C, add 10% sodium hypochlorite under stirring Solution 80g, obtain carboxyl maltodextrin solution.

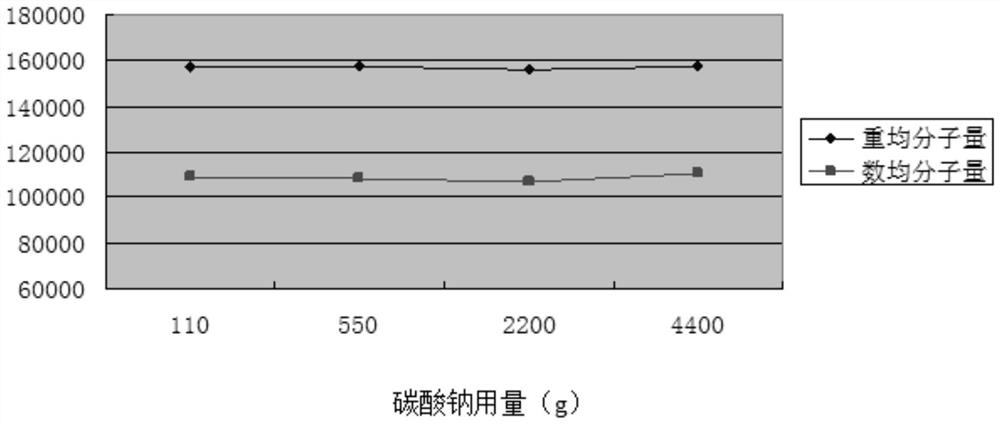

[0037] Carboxymaltodextrin solution and ferric chloride solution (concentration of ferric chloride 75% w / w, prepared by adding 220 g of ferric chloride hexahydrate and water) were first mixed, stirred, temperature controlled at 50-70°C, and peristaltic Add sodium carbonate solution (concentration 25% w / w, prepared by adding water to 110 g of sodium carbonate) dropwise by the pump at a constant speed, set the flow rate, and control the addition of sodium carbonate solution within 0.3 hours. After completion of the reaction, add 30% sodium hydroxide solution to adjust the pH value of the solution to 10.0 to 12.0, control the temperature at 50 to 70° C., and stir fo...

Embodiment 2

[0039] The preparation of carboxy maltodextrin solution is the same as in Example 1.

[0040] Carboxymaltodextrin solution and ferric chloride solution ((concentration of ferric chloride 75% w / w, prepared by adding water to 220 g of ferric chloride hexahydrate) were first mixed, stirred, and the temperature was controlled at 50-70°C, and Add sodium carbonate solution (concentration 25% w / w, prepared by adding water to 110g of sodium carbonate) with the peristaltic pump at a constant speed, set the flow rate, and control the addition of sodium carbonate solution within 0.5 hours. After the reaction is completed, it will be cured by acid, alkali and high temperature Obtain stable iron carboxy maltose solution, then add 160 ml of absolute ethanol to precipitate iron carboxy maltose.

Embodiment 3

[0042] The preparation of carboxy maltodextrin solution is the same as in Example 1.

[0043]Carboxymaltodextrin solution and ferric chloride solution (concentration of ferric chloride 75% w / w, prepared by adding 220 g of ferric chloride hexahydrate and water) were first mixed, stirred, temperature controlled at 50-70°C, and peristaltic Pump the sodium carbonate solution (concentration 25% w / w, prepared by adding water to 110 g of sodium carbonate) dropwise at a constant speed, set the flow rate, and control the addition of the sodium carbonate solution within 1.0 hour. After the reaction is completed, solidify with acid, alkali and high temperature to obtain a stable iron carboxy maltose solution, and then add 160 ml of absolute ethanol to precipitate iron carboxy maltose.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com