A method and device for growing high-quality silicon carbide crystals

A technology of high-quality silicon carbide and growth methods, applied in crystal growth, single crystal growth, single crystal growth, etc., can solve problems such as unstable temperature field, affecting nucleation quality, vibration and displacement of silicon carbide powder, etc., to achieve improved The quality of crystal growth, the promotion of multi-core competition and merger, and the effect of regulation and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

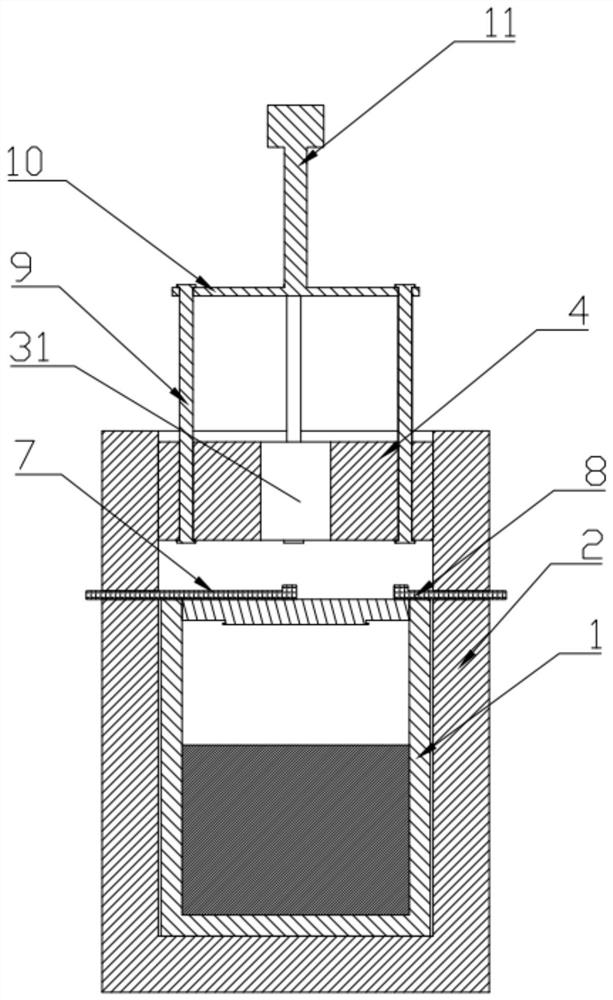

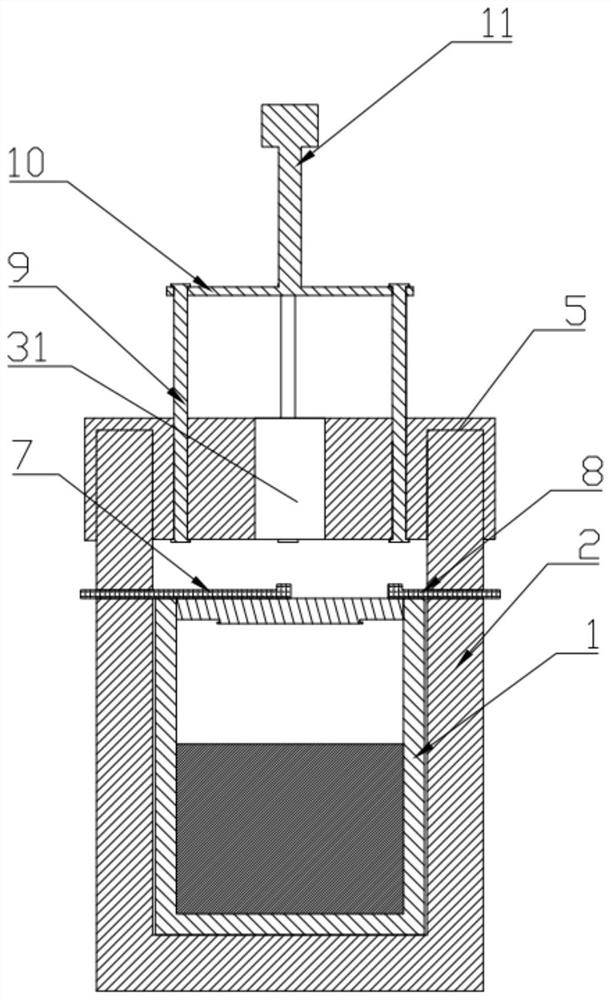

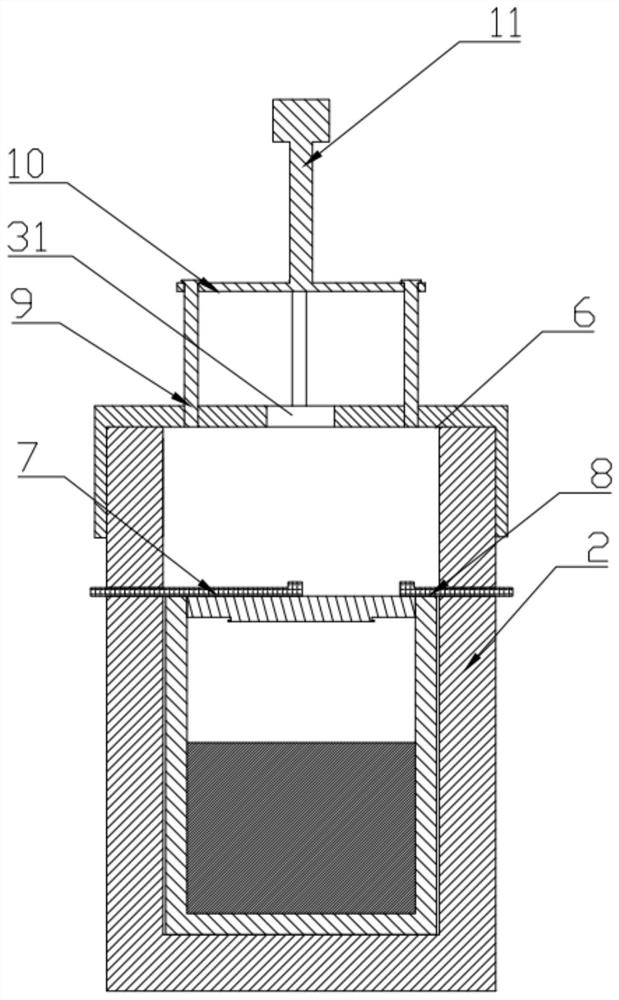

[0058] refer to Figure 1-4 , this embodiment provides a crystal growth device, the device includes a crucible 1, a holding cylinder 2 and a furnace body, the bottom of the crucible 1 is used for placing silicon carbide raw materials, and the top of the crucible 1 is used for setting seed crystals; the holding cylinder 2 has A hollow cavity with one end open and the other closed; the crucible 1 is placed in the hollow cavity; the heat preservation cover 3 is arranged at the opening of the heat preservation cylinder 2, the top of the heat preservation cover 3 is provided with a heat dissipation hole 31, and the side wall of the heat preservation cover 3 is connected to the heat preservation cylinder. The top side wall of 2 abuts, and the heat preservation cover 3 can move along the top side wall of the heat preservation cylinder 2. The heat preservation cover 3 is provided with a heat dissipation hole 31; the furnace body is used for placing the crucible 1 and the heat preservat...

Embodiment 2

[0074] A method for growing silicon carbide crystals using the device described in Embodiment 1, the method comprising the steps of:

[0075] (1) Assembly stage: the seed crystal is placed on the top of the crucible, and the silicon carbide raw material is filled at the bottom of the crucible; the crucible and the heat preservation cylinder are assembled, the assembled crucible is placed in the furnace body of the crystal growth furnace and sealed, and the bottom of the heat preservation cover is sealed. The distance from the top cover of the crucible is L, and L is 10-300mm;

[0076] (2) Vacuum the furnace body to 10 -6 Below mbar, then pass high-purity inert gas to 300~500mbar, repeat this process 2~3 times, and finally vacuum the furnace body to 10 -6 Below mbar;

[0077] (3) Heating stage: control the detection temperature of the first temperature measuring device at the center of the top of the crucible to rise to T1 and synchronously increase the pressure to P1, and cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com