Metal-air battery positive electrode membrane capable of adsorbing CO2 and preparation method of metal-air battery positive electrode membrane

A technology of air battery and cathode film, applied in battery electrodes, fuel cell type half cells and primary cell type half cells, circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

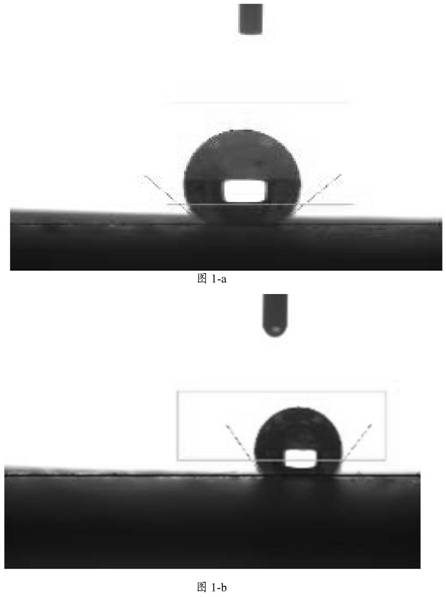

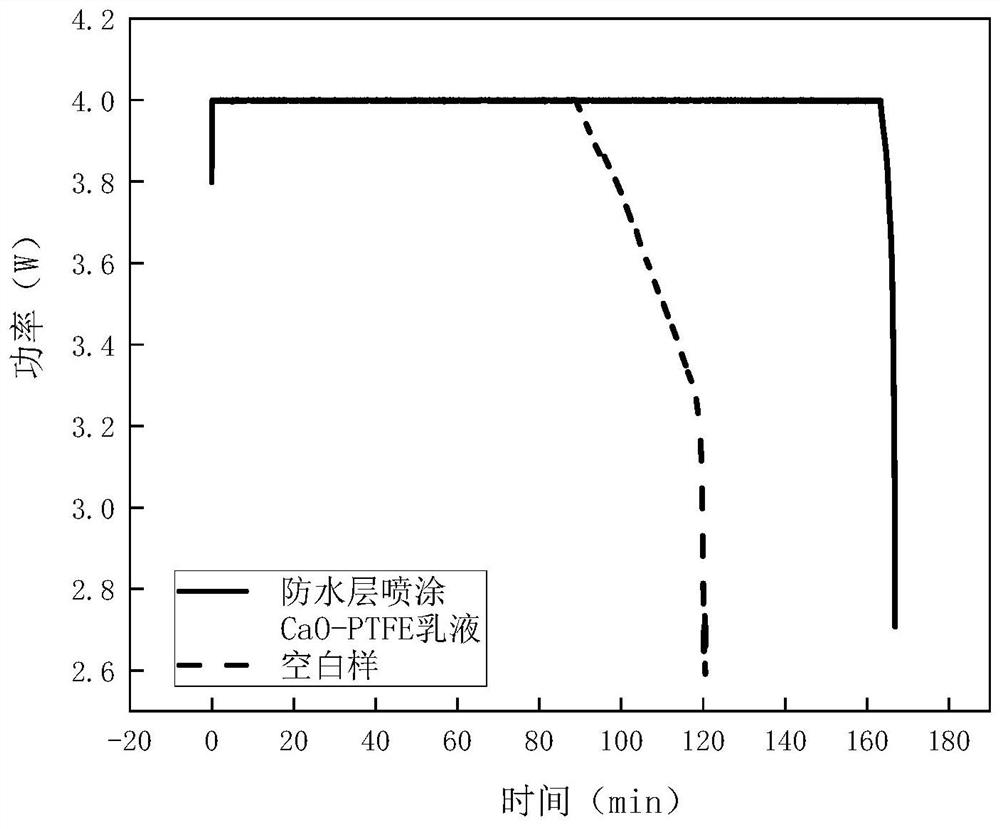

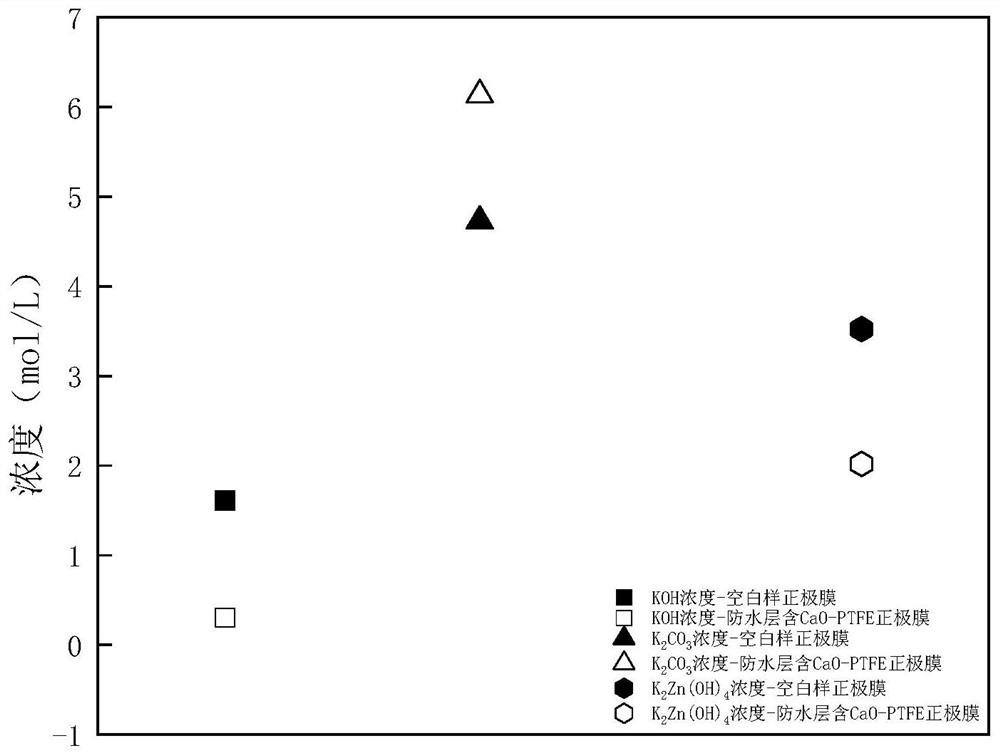

Image

Examples

Embodiment 1

[0027] Adsorbable CO 2 The preparation method of metal-air battery cathode film, comprises steps:

[0028] (1) Put 50g CaO and 280mL ethanol in a beaker, turn on the high-speed disperser and stir at a speed of 800r / min for 30min, until CaO is uniformly dispersed in ethanol to obtain an absorption liquid;

[0029] (2) Keep stirring the absorption liquid, add 75g of polytetrafluoroethylene emulsion (PTFE) with a solid content of 60% into the absorption liquid at room temperature, and stir the mixed solution for 2h with a rotating speed of 1500r / min to obtain a CaO-PTFE emulsion ;

[0030] (3) Add the CaO-PTFE emulsion prepared above into a pneumatic booster spray gun, evenly spray on the blank side of the nickel mesh collector fluid, and spray the manganese-lanthanide catalyst on the other side;

[0031] (4) Use a pair of rollers to roll at a high temperature of 100°C until the thickness of the membrane electrode is 0.7mm, put the air electrode membrane in a vacuum atmosphere ...

Embodiment 2

[0033] Adsorbable CO 2 The preparation method of metal-air battery cathode film, comprises steps:

[0034] (1) Mix 80g Na 2 o 2 Put in a beaker with 400mL isopropanol, turn on the high-speed disperser and stir at a speed of 600r / min for 60min until Na 2 o 2 Uniformly dispersed in isopropanol to obtain absorption liquid;

[0035] (2) Keep stirring the absorption liquid, add 50g PTFE into the absorption liquid at normal temperature, and stir the mixed liquid for 3h at a speed of 1200r / min to obtain Na 2 o 2 - PTFE emulsion;

[0036] (3) Na prepared above 2 o 2 - PTFE emulsion is added to the pneumatic booster spray gun, evenly sprayed on the blank side of the nickel mesh collector, and the other side is sprayed with manganese-lanthanide catalyst;

[0037] (4) Use a pair of rollers to roll at a high temperature of 120 ° C until the thickness of the membrane electrode is 0.8 mm, put the air electrode film in a vacuum atmosphere furnace for sintering at 500 ° C for 3 h, an...

Embodiment 3

[0039] Adsorbable CO 2 The preparation method of metal-air battery cathode film, comprises steps:

[0040] (1) Put 100g of soda lime and 500mL of acetone in a beaker, turn on the high-speed disperser and stir for 60min at a speed of 500r / min, until the soda lime is evenly dispersed in the acetone to obtain an absorption solution;

[0041] (2) Keep stirring the absorption solution, add 100g PTFE in the absorption solution at normal temperature, and stir the mixed solution for 3h with a rotating speed of 2000r / min to obtain a soda lime-PTFE emulsion;

[0042] (3) The soda lime-PTFE emulsion of above-mentioned preparation is added in the pneumatic booster spraying gun, evenly sprayed on the blank side of the nickel mesh collector fluid, the other side is then sprayed with manganese lanthanide catalyst;

[0043] (4) Use a pair of rollers to roll at a high temperature of 100 ° C until the thickness of the membrane electrode is 0.9 mm, put the air electrode film in a vacuum atmospher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com