Preparation and application of PEI@COF composite membrane

A composite membrane, COF-LZU1 technology, applied in the field of preparation of PEI@COF composite membrane, can solve problems such as poor mechanical properties, achieve the effect of improving mechanical properties and increasing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

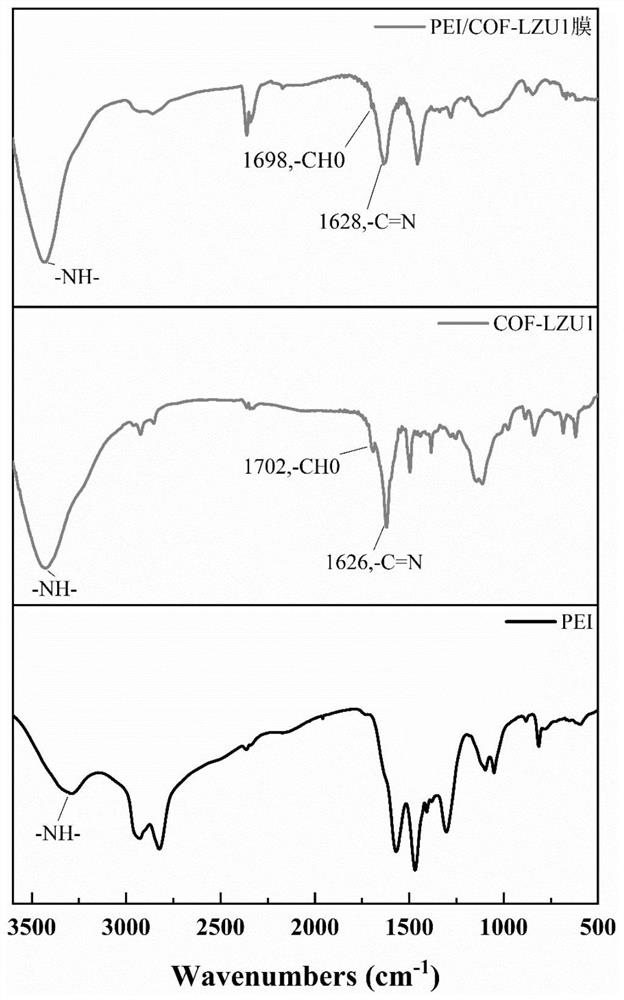

[0017] Preparation of COF-LZU1: Dissolve 100mg of trimesaldehyde and 100mg of p-phenylenediamine in 20ml of dioxane, then slowly add 0.4ml of 3mol / L acetic acid solution, seal and let stand for three days. After the reaction was completed, the precipitate was washed three times with methanol, and then vacuum-dried to obtain COF-LZU1 powder.

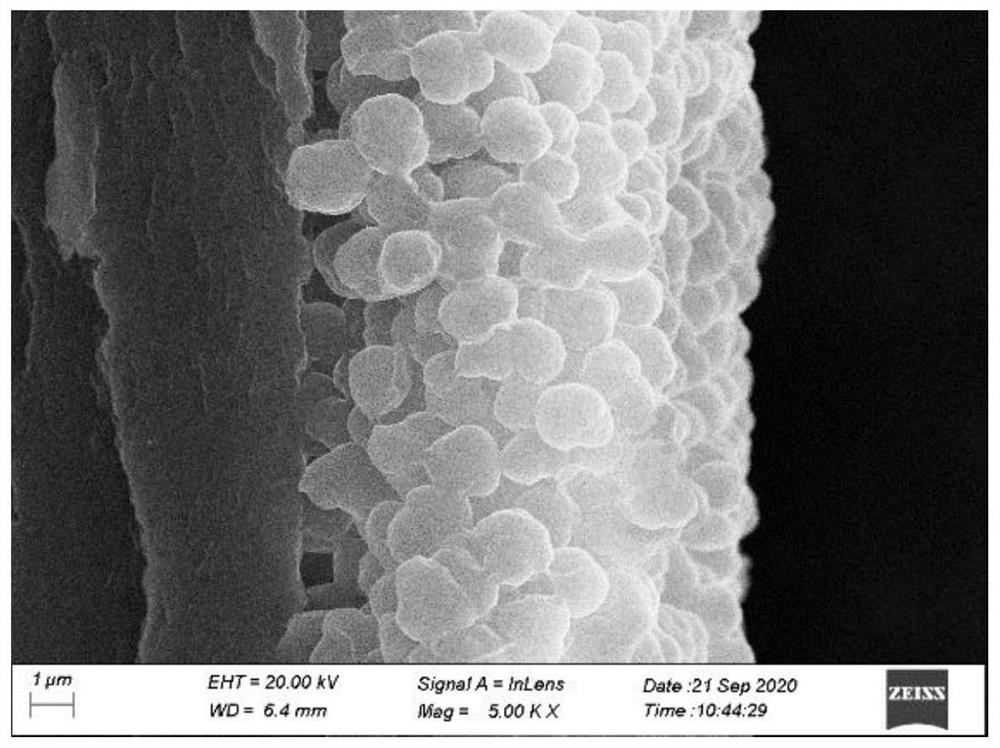

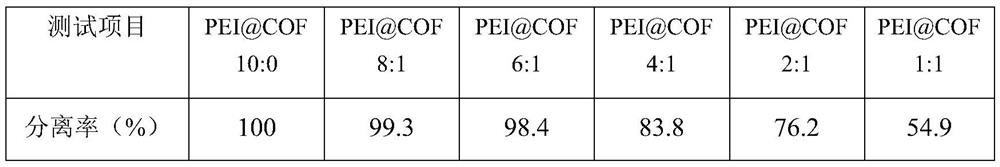

[0018] Preparation of PEI@COF composite membrane: Add cross-linking agent 1,4-butanediol diglycidyl ether or homophenylene to the mixed aqueous solution of PEI and COF-LZU1 powder with a mass ratio of 10:1 (total mass: 33 mg) Triformyl chloride (mass ratio to PEI is 1:1), after ultrasonic mixing, reacted for 12h, and then suction filtered to form a film.

Embodiment 2

[0020] Preparation of COF-LZU1: Dissolve 100mg of trimesaldehyde and 100mg of p-phenylenediamine in 20ml of dioxane, then slowly add 0.4ml of 3mol / L acetic acid solution, seal and let stand for three days. After the reaction was completed, the precipitate was washed three times with methanol, and then vacuum-dried to obtain COF-LZU1 powder.

[0021] Preparation of PEI@COF composite membrane: Add crosslinking agent 1,4-butanediol diglycidyl ether or phenylene to the mixed aqueous solution of PEI and COF-LZU1 powder with a mass ratio of 8:1 (total mass: 33 mg) Triformyl chloride (mass ratio to PEI is 1:1), after ultrasonic mixing, reacted for 12h, and then suction filtered to form a film.

Embodiment 3

[0023] Preparation of COF-LZU1: Dissolve 100mg of trimesaldehyde and 100mg of p-phenylenediamine in 20ml of dioxane, then slowly add 0.4ml of 3mol / L acetic acid solution, seal and let stand for three days. After the reaction was completed, the precipitate was washed three times with methanol, and then vacuum-dried to obtain COF-LZU1 powder.

[0024] Preparation of PEI@COF composite membrane: Add cross-linking agent 1,4-butanediol diglycidyl ether or phenylene to the mixed aqueous solution of PEI and COF-LZU1 powder with a mass ratio of 6:1 (total mass: 33 mg) Triformyl chloride (mass ratio to PEI is 1:1), after ultrasonic mixing, reacted for 12h, and then suction filtered to form a film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com