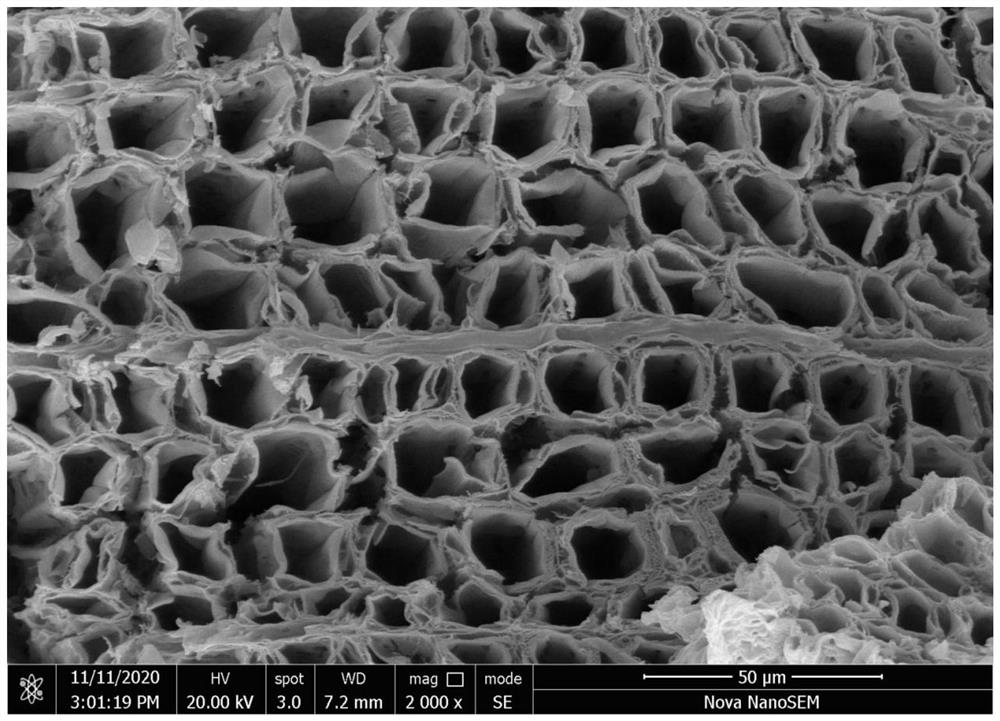

Porous Co3O4 catalyst with wood 3D ordered pore structure for mercury removal and preparation method of porous Co3O4 catalyst

A pore structure and catalyst technology, which is applied in the field of Co3O4 catalysts with ordered pores, can solve the problems of poor thermal stability of carbon materials, and achieve the effects of promoting mass transfer, enhancing anchoring, and high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0030] Saw the wooden column into thin circular slices, select a suitable position, and cut into small wood pieces of 5×3×2mm. Put 2g of small wood chips in a water bath at 95°C and boil for 6 hours. The boiled wood chips were dried in an oven at 80°C for 12 hours.

[0031] Weigh 10 g of cobalt nitrate solid and 40 g of deionized water to prepare a cobalt nitrate solution with a mass fraction of 20%, and use ultrasonic stirring for 10 min to accelerate dissolution. Dip the wood chips into the solution, and place them in a water bath at 30°C for 24 hours at a constant temperature. Remove the safety film, absorb the moisture, and put it in a blast drying oven at 60°C for 24 hours.

[0032] The dried samples were placed in a tube furnace for carbonization treatment under the protection of inert gas nitrogen, the gas flow rate was 60mL / min, the heating rate was 1°C / min, the carbonization temperature was 500°C, and the carbonization time was 3h. The sample was taken out and plac...

Embodiment example 2

[0035]Saw the wooden column into thin circular slices, select a suitable position, and cut into small wood pieces of 5×3×2mm. Put 2g of small wood chips in a water bath at 90°C and boil for 4 hours. The boiled wood chips were dried in an oven at 70°C for 14 hours.

[0036] Weigh 5 g of cobalt nitrate solid and 45 g of deionized water to prepare a cobalt nitrate solution with a mass fraction of 10%, and use ultrasonic stirring for 10 min to accelerate dissolution. Put the wood chips into the solution for immersion, and place them in a water bath at 20°C for 12 hours at a constant temperature. Remove the safety film, absorb the moisture, and put it in a blast drying oven at 80°C for 36 hours.

[0037] The dried samples were placed in a tube furnace for carbonization treatment under the protection of inert gas nitrogen, the gas flow rate was 50mL / min, the heating rate was 2°C / min, the carbonization temperature was 450°C, and the carbonization time was 4h. The sample was taken ...

Embodiment example 3

[0040] Saw the wooden column into thin circular slices, select a suitable position, and cut into small wood pieces of 5×3×2mm. Put 2g of small wood chips in a water bath at 85°C and boil for 6 hours. The boiled wood chips were dried in an oven at 60°C for 8 hours.

[0041] Weigh 15 g of cobalt nitrate solid and 35 g of deionized water to prepare a cobalt nitrate solution with a mass fraction of 30%, and use ultrasonic stirring for 10 min to accelerate the dissolution. Put the wood chips into the solution for immersion, and place them in a water bath at 40°C for 16 hours at a constant temperature. Remove the safety film, absorb the moisture, and put it in a blast drying oven at 70°C for 28 hours.

[0042] The dried samples were placed in a tube furnace for carbonization treatment under the protection of inert gas nitrogen, the gas flow rate was 70mL / min, the heating rate was 3°C / min, the carbonization temperature was 550°C, and the carbonization time was 2h. The sample was t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com