System for treating high-concentration organophosphorus wastewater and treatment process thereof

An organic phosphorus, high-concentration technology, applied in filtration treatment, water/sewage treatment, heating water/sewage treatment, etc., can solve problems such as inability to continuously operate phosphorus removal effect, easy to pollute the environment, and poor wastewater treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

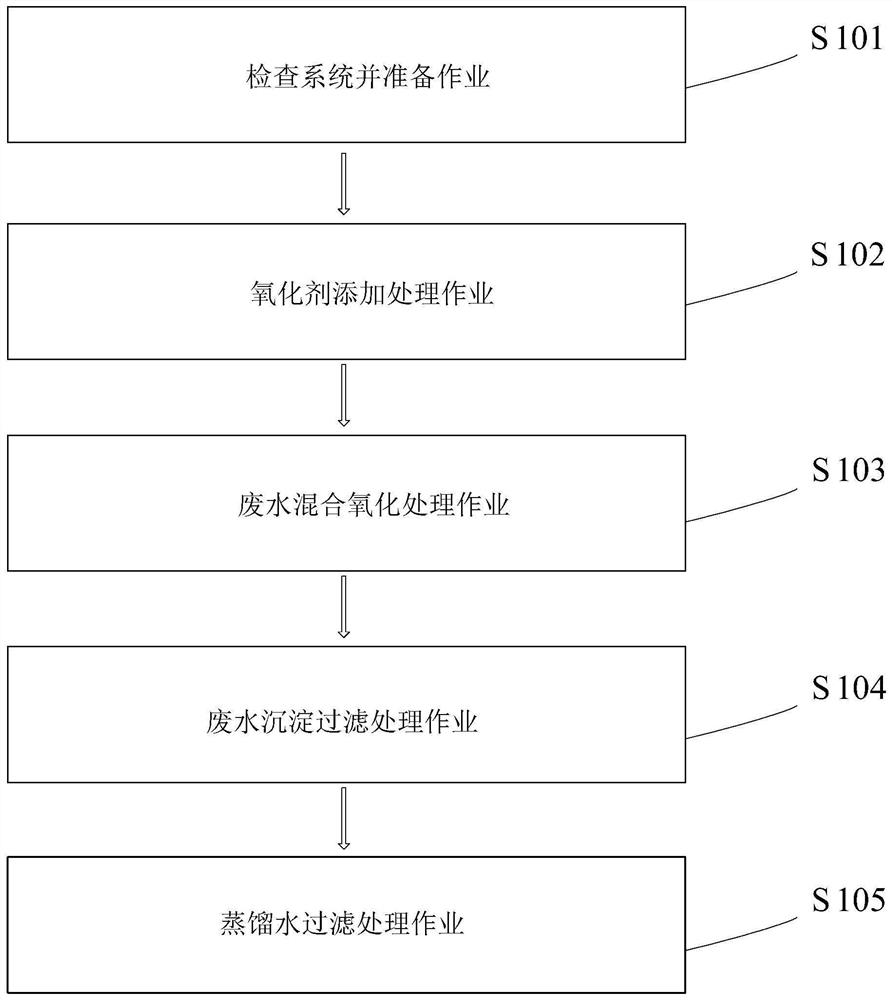

[0061] Step 1: Check the system and prepare for operation, debug equipment, and prepare for system work;

[0062] Step 2: Oxidant addition treatment operation, take wastewater to adjust the pH value to 3, add oxidant, stir evenly, and then statically react for 2 hours for advanced oxidation;

[0063] Step 3: Wastewater mixed oxidation treatment operation, take the wastewater after advanced oxidation and add acid to adjust the pH value to 3, conduct a first-level iron-carbon micro-electrolysis test under aeration conditions, the reaction time is about 2 hours, add liquid alkali to adjust after the reaction When the pH value reaches 9, let it stand still for precipitation, take the supernatant of the first-level iron-carbon effluent and add acid to adjust the pH value to 3, and carry out the second-level iron-carbon micro-electrolysis reaction under aeration conditions. The reaction time is 2 hours, and the acid is added after the reaction is completed. Adjust the pH to 3;

[0...

Embodiment 4-7

[0072] Step 1: Check the system and prepare for operation, debug equipment, and prepare for system work;

[0073] Step 2: Oxidant addition treatment operation, take wastewater to adjust the pH value to 3, add oxidant, stir evenly, and then statically react for 2 hours for advanced oxidation;

[0074] Step 3: Wastewater mixed oxidation treatment operation, take the wastewater after advanced oxidation and add acid to adjust the pH value to 3, conduct a first-level iron-carbon micro-electrolysis test under aeration conditions, the reaction time is about 2 hours, add liquid alkali to adjust after the reaction When the pH value reaches 9, let it stand still for precipitation, take the supernatant of the first-level iron-carbon effluent and add acid to adjust the pH value to 3, and carry out the second-level iron-carbon micro-electrolysis reaction under aeration conditions. The reaction time is 2 hours, and the acid is added after the reaction is completed. Adjust the pH to 3;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com