SiBCN ceramic precursor and synthesis method thereof

A technology of ceramic precursors and synthesis methods, applied in the field of new materials, can solve problems such as by-products that require low temperature conditions, and achieve the effects of high atom utilization, good solubility, and high ceramic yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

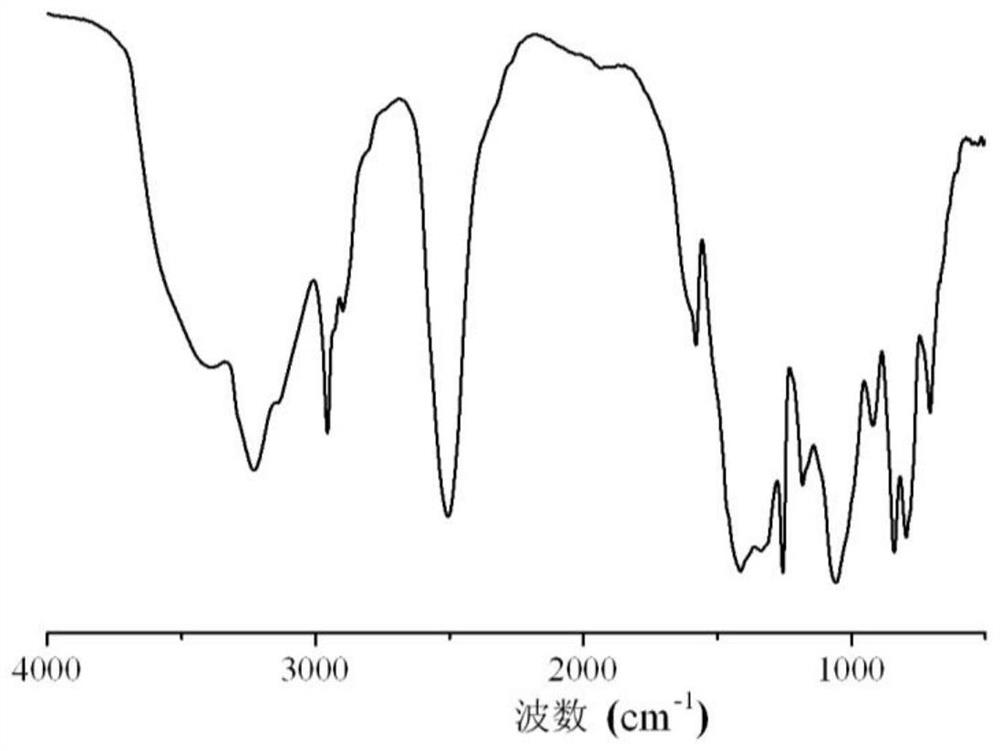

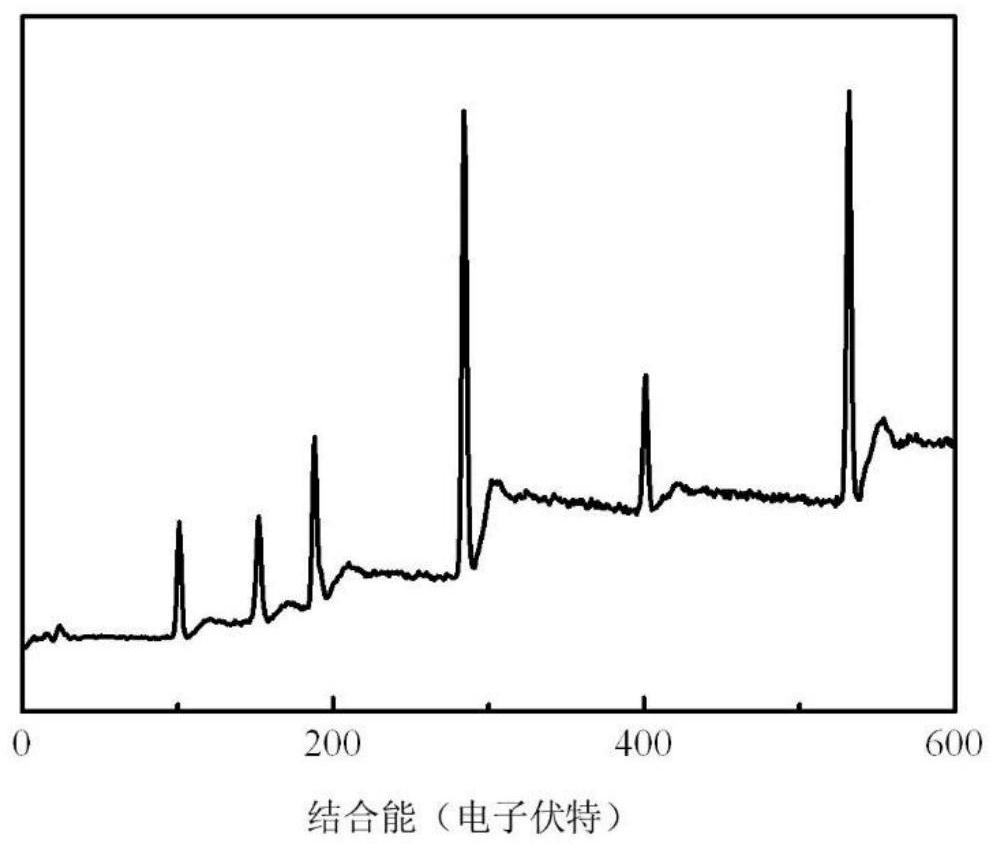

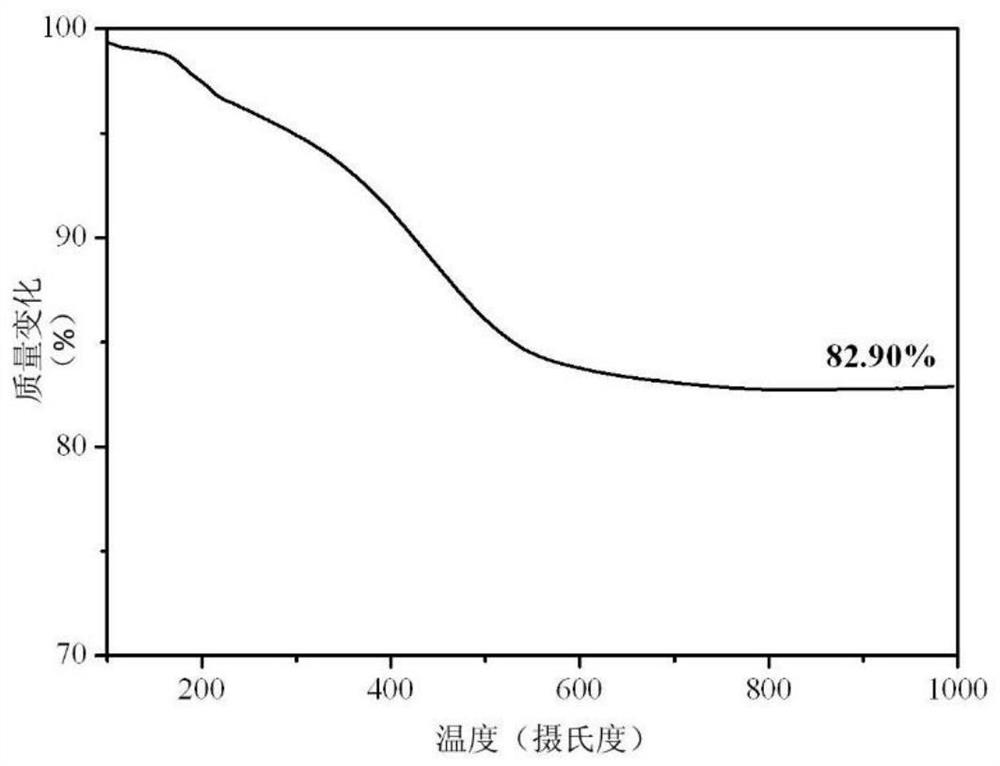

[0023] The present invention proposes a kind of synthetic method of SiBCN ceramic precursor, comprises the following steps:

[0024] S1: Weigh decaborane and organosilicon compound according to the ratio of substances to 1:1;

[0025] S2: dissolving the decaborane in anhydrous tetrahydrofuran to obtain a decaborane solution;

[0026] Dissolving the organosilicon compound in anhydrous tetrahydrofuran to obtain an organosilicon compound solution;

[0027] S3: select a reactor with stirring, replace the air in the reactor with an inert gas, and then add the decaborane solution into the reactor;

[0028] S4: under stirring conditions, add the organosilicon compound solution into the reaction kettle;

[0029] S5: After the feeding is completed, continue to stir at room temperature for 10-20 hours, and then distill under reduced pressure for 10-20 hours under the condition of a constant temperature water bath at 60° C. to remove the solvent to obtain a SiBCN ceramic precursor.

...

Embodiment 1

[0046] The present embodiment provides a kind of synthetic method of SiBCN ceramic precursor, comprises the following steps:

[0047] S1: Weigh 0.1 mol of decaborane and 0.1 mol of 1,3-bis(aminopropyl)tetramethyldisiloxane.

[0048] S2: Dissolving decaborane in anhydrous tetrahydrofuran to obtain a decaborane solution; the concentration of decaborane in the decaborane solution is 0.2 mol / L.

[0049] Dissolve 1,3-bis(aminopropyl)tetramethyldisiloxane in anhydrous tetrahydrofuran to obtain organosilicon compound solution; 1,3-bis(aminopropyl)tetramethyldisiloxane in organosilicon compound solution The molar concentration of ether is 0.2 mol / L.

[0050] S3: Select a reactor with stirring, replace the air in the reactor with nitrogen (introduction speed is 0.5L / min), and then add the decaborane solution to the reactor;

[0051] S4: Under the condition of stirring, add the organosilicon compound solution into the reaction kettle at a rate of 20 mL / min.

[0052] S5: After the add...

Embodiment 2

[0055] The present embodiment provides a kind of synthetic method of SiBCN ceramic precursor, comprises the following steps:

[0056] S1: Weigh 0.1 mol of decaborane and 0.1 mol of [3-(trimethoxysilyl)propyl]ethylenediamine.

[0057] S2: Dissolving decaborane in anhydrous tetrahydrofuran to obtain a decaborane solution; the concentration of decaborane in the decaborane solution is 0.4 mol / L.

[0058] Dissolve [3-(trimethoxysilyl)propyl]ethylenediamine in anhydrous tetrahydrofuran to obtain an organosilicon compound solution; [3-(trimethoxysilyl)propyl]ethylenediamine in the organosilicon compound solution The molar concentration of the amine substance was 0.6 mol / L.

[0059] S3: Select a reactor with stirring, replace the air in the reactor with nitrogen (introduction speed is 1.0L / min), and then add the decaborane solution to the reactor;

[0060] S4: Under the condition of stirring, add the organosilicon compound solution into the reaction kettle at a rate of 10 mL / min.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com