Lithium ion battery binder as well as preparation method and application thereof

A lithium-ion battery and binder technology, applied in the direction of adhesive, secondary battery, battery electrode, etc., can solve the problem of insufficient voltage resistance performance, and achieve the effect of improving effect, high coulombic efficiency, and excellent bonding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

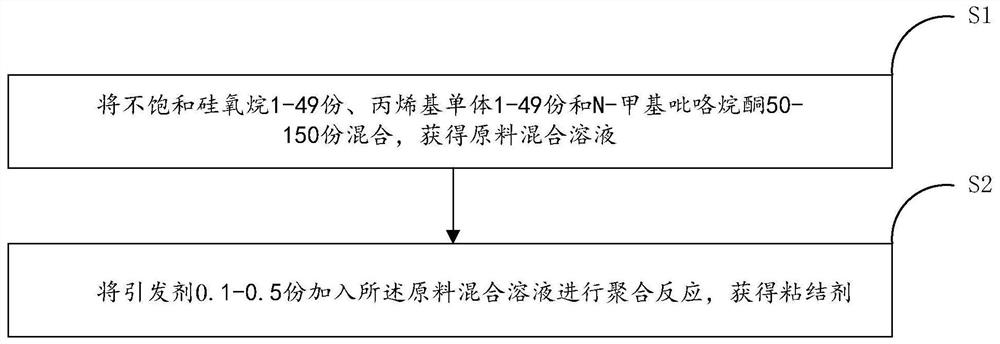

[0048] According to another typical embodiment of the present invention, a method for preparing a lithium ion battery binder is provided, the method comprising:

[0049] S1. Mix 1-49 parts by weight of unsaturated siloxane, 1-49 parts by weight of acrylic monomer and 50-150 parts by weight of N-methylpyrrolidone to obtain a mixed solution of raw materials;

[0050] S2. Add 0.1-0.5 parts by weight of an initiator to the raw material mixture solution to carry out polymerization reaction to obtain a binder.

[0051] As an optional embodiment, adding 0.1-0.5 parts by weight of the initiator to the raw material mixed solution to carry out a polymerization reaction to obtain a binder, specifically includes:

[0052] Adding 0.1-0.5 parts by weight of initiator to the raw material mixed solution, performing polymerization reaction under the protection of nitrogen to obtain the binder, the temperature of the polymerization reaction is 50°C-80°C.

[0053] According to another typical e...

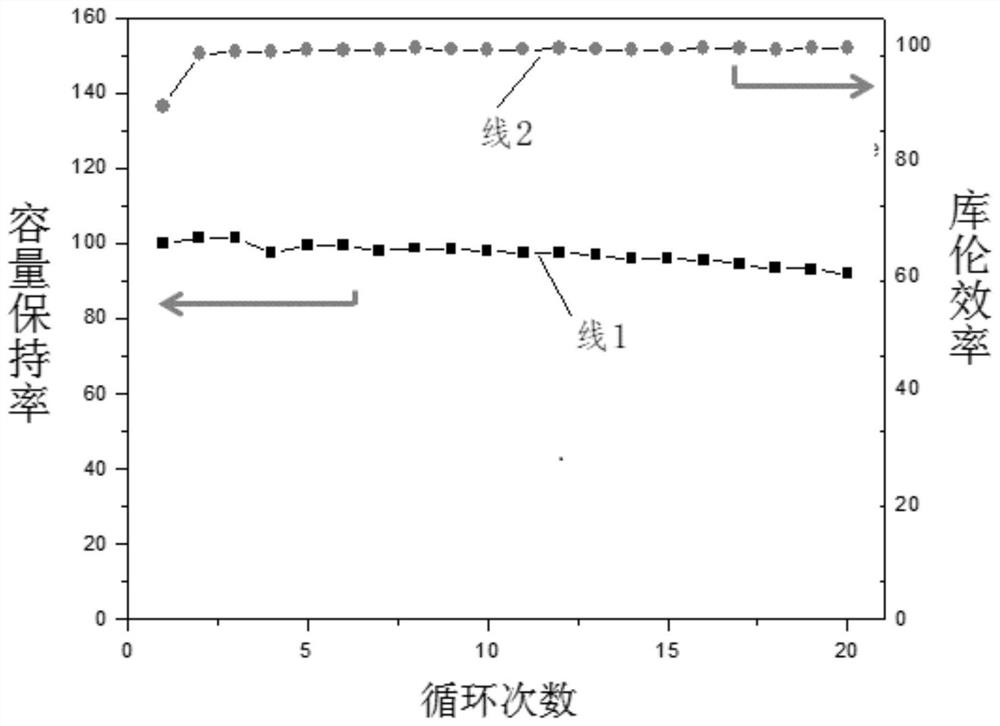

Embodiment 1

[0063] In 100 parts by weight of N-methylpyrrolidone solvent, add 5 parts by weight of vinyltrimethoxysilane first monomer and 45 parts by weight of lithium acrylate second monomer, then add 0.25 parts by weight of initiator diperoxide Benzoyl, under the protection of nitrogen, was subjected to solution copolymerization at a temperature of 50° C. to 80° C. for 2 hours to obtain a viscous colorless and transparent glue solution with a solid content of 30%.

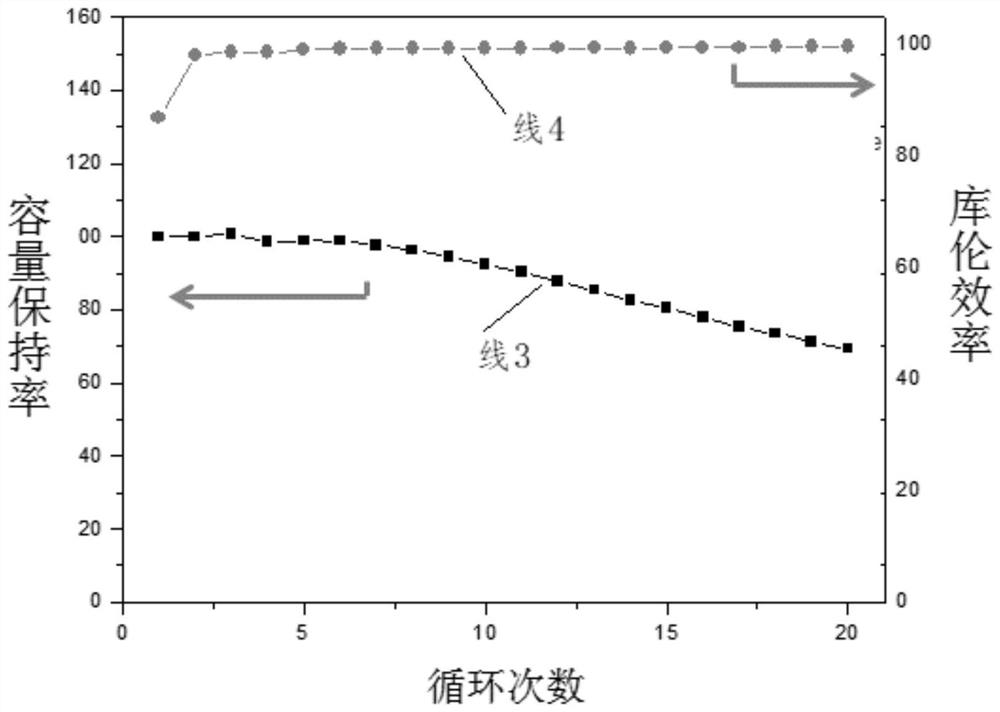

Embodiment 2

[0065] In 150 parts by weight of N-methylpyrrolidone solvent, add 10 parts by weight of vinyltriethoxysilane first monomer and 40 parts by weight of lithium acrylate second monomer, then add 0.3 parts by weight of initiator azo Diisobutyronitrile was subjected to solution copolymerization at a temperature of 50° C. to 80° C. for 2 hours under the protection of nitrogen to obtain a viscous colorless and transparent glue solution with a solid content of 24.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com