Spiral fiber wrapped with perovskite quantum dots, and preparation method and device

A helical fiber and perovskite technology, applied in fiber processing, fiber chemical characteristics, chemical instruments and methods, etc., can solve the problems of strict material selection and environmental requirements, poor stability of perovskite quantum dots, and easy oxidation. , to achieve the effect of strong experimental repeatability, low cost and stable morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention provides a method for preparing a helical fiber wrapped with perovskite quantum dots, prepared by a microfluidic method, comprising the following steps:

[0034] S1. Build a microfluidic device

[0035] Take several capillary tubes and prepare a group of capillary array, reaction tube, dispersion tube and external phase tube, connect the capillary array to one end of the reaction tube, and nest it in the reaction tube; the other end of the reaction tube is connected to one end of the dispersion tube, and Nested in the dispersing tube; the other end of the dispersing tube is nested in the external phase tube, and the microfluidic device is built;

[0036] S2. Preparation of helical fibers wrapped with perovskite quantum dots

[0037]Pump different perovskite quantum dot precursors into each channel of the capillary array, pump the continuous phase solution into the dispersion tube, and pump the external phase solution into the external phase tube; ...

Embodiment 1

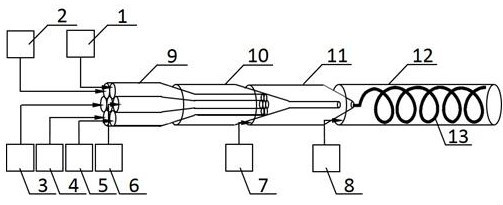

[0044] refer to figure 1 , the present embodiment provides a device for preparing helical fibers wrapped with perovskite quantum dots, including a capillary array 9, a reaction tube 10, a dispersion tube 11, an external phase tube 12, and a liquid-feeding power device; the capillary array 9 consists of seven The liquid outlet end of the capillary array 9 (the port is pointed) is connected and nested in the liquid inlet end of the reaction tube 10, and the liquid outlet end of the reaction tube 10 (the port is pointed) is connected and nested. Set on the liquid inlet end of the dispersing pipe 11, the liquid outlet end of the dispersing pipe 11 (the port is pointed) is connected and nested in the liquid inlet end of the external phase pipe 12; the number of the liquid inlet power devices is eight, and the inlet The hydraulic power device includes a liquid inlet pump and a syringe connecting needle, the liquid inlet pump is connected with the syringe connecting needle through a ...

Embodiment 2

[0052] The device provided in this example for preparing helical fibers wrapped with perovskite quantum dots is the same as that in Example 1.

[0053] The preparation method of the helical fiber wrapped perovskite quantum dots in this embodiment is as follows:

[0054] S1. Build a microfluidic device

[0055] Referring to Example 1

[0056] S2. Preparation of helical fibers wrapped with perovskite quantum dots

[0057] Push the cesium bromide solution to one liquid inlet in the capillary array 9 by the second liquid inlet power device 2, push the lead bromide solution to another liquid inlet in the capillary array 9 by the fifth liquid inlet power device 5 Make the two kinds of solutions flow out from the liquid outlet of the capillary array 9, and flow into the reaction tube 10 to mix and react; push the polyvinylidene fluoride solution in the dispersion tube 11 through the seventh liquid inlet power device 7; The eight-inlet power device 8 injects deionized water into th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com