Composite film layer for aluminum alloy surface and preparation method thereof

A technology of aluminum alloy surface and composite film layer, which is applied in the direction of metal material coating process, coating, superimposed layer plating, etc., can solve the problem of increasing the coating thickness of the aluminum alloy surface, peeling off of the film layer and the substrate, and peeling off of the film layer and other issues, to achieve the effect of improving corrosion resistance and wear resistance, improving corrosion resistance and hardness, wear resistance and shortening hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

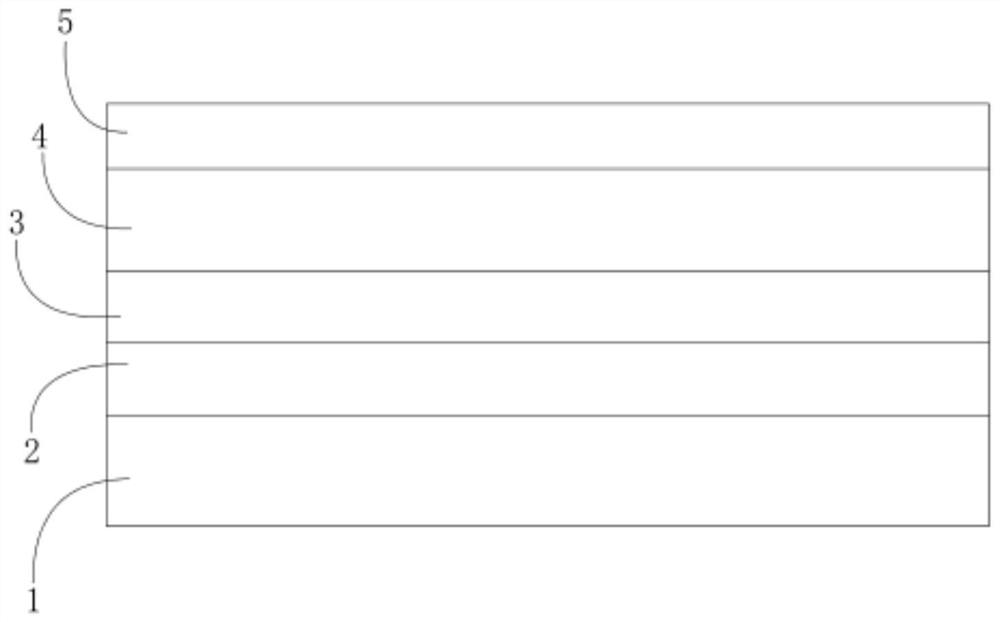

[0052] refer to figure 1 , the present embodiment discloses a composite film layer for the surface of an aluminum alloy, including a Cr layer 2, a CrWC layer 3, a WC layer 4 and a DLC layer 5 covering the surface of an aluminum alloy 1 in sequence, wherein the thickness of the Cr layer 2 is 2 μm, and the total thickness of the composite film layer is 4 μm.

[0053] This embodiment also discloses a method for preparing a composite film layer on the surface of an aluminum alloy, comprising the following steps:

[0054] Step 1: Ultrasonic cleaning the aluminum alloy to be coated, and then heating the cleaned aluminum alloy to 220°C in a vacuum coating chamber, evacuating, and keeping the temperature in the vacuum coating chamber at 220°C.

[0055] Step 2, wait for the background vacuum in the vacuum coating chamber to reach 5×10 -3 At Pa, argon gas was introduced, and the intake volume of argon gas was controlled to 80 sccm to make the air pressure reach 0.1 Pa, the bias voltag...

Embodiment 2

[0061] The difference with embodiment 1 only lies in:

[0062] In step 3, adjust the intake volume of argon gas to 240sccm, make the air pressure reach 0.3Pa, set the bias voltage to -120V, turn on the high-power coating power supply of the Cr target, and set the current of the Cr target to 50A, and deposit the Cr layer 150min, close the Cr target.

Embodiment 3

[0064] The difference with embodiment 1 only lies in:

[0065] In step 4, feed acetylene, and control the air intake of acetylene to 80sccm, make the air pressure reach 0.3Pa, set the bias voltage to -120V, turn on the Cr target and the WC target at the same time, and set the current of the Cr target to 35A and Set the current of the WC target to 16A, deposit the CrWC layer for 40 minutes, and turn off the Cr target and the WC target.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com