Preparation method of anti-corrosion zirconium-based amorphous alloy composite material coating

A zirconium-based amorphous alloy and composite material technology, which is applied in the field of material science and engineering, can solve the problems of reducing the corrosion resistance of the coating, the decrease of the corrosion resistance of the coating, and the uneven composition of the coating, so as to improve the corrosion resistance , reduce the preparation cost, and reduce the effect of pore defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The preparation of zirconium-based amorphous alloy composite material coating based on vacuum induction melting gas atomized spherical amorphous powder and synchronous powder feeding includes the following steps:

[0042] Step 1: Powder preparation and mixing:

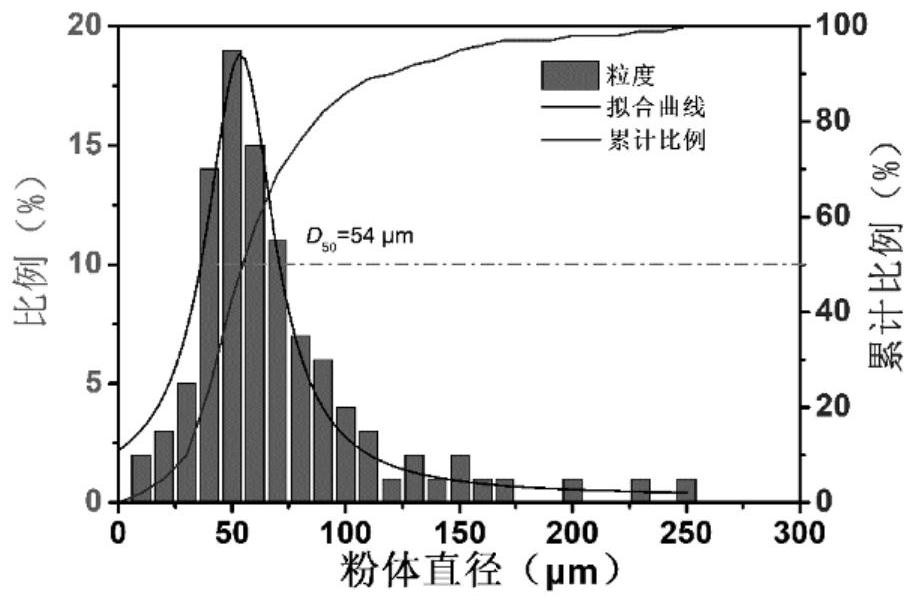

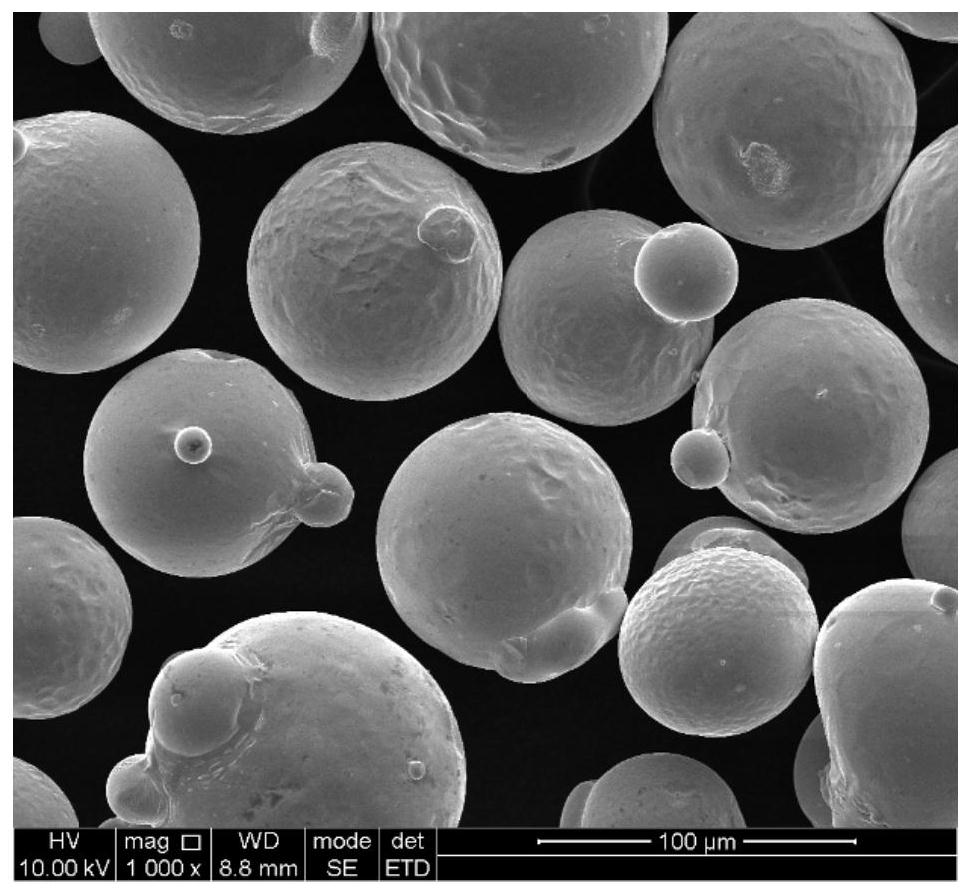

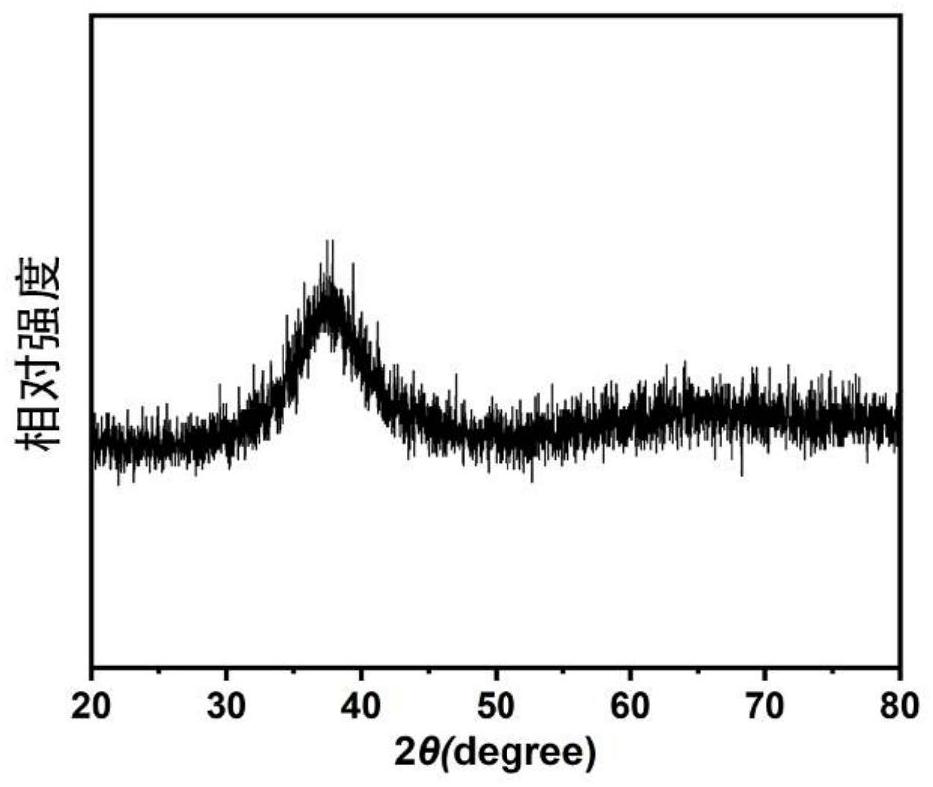

[0043]Zr, Cu, Ni and Al are mixed according to the atomic ratio Zr:Cu:Ni:Al=50.4:28:9:12.3, and 2.16kg of raw materials are selected to prepare zirconium-based amorphous alloy high-spherical preforms by vacuum induction melting gas atomization technology. For alloy powder, the initial atomizing gas pressure is 3MPa, and the alloy melt temperature is 1200°C. 1.73kg of zirconium-based amorphous alloy high-spherical pre-alloyed powder is prepared, and the powder yield is about 80%. After powder making, the powder is sieved, and the powder of 45 μm-120 μm is selected, and the powder and SiC nano powder with a diameter of 55 nm are ball milled by a ball mill for 18 minutes. The mass ratio of SiC nano powder is 5%, so...

Embodiment 2

[0049] The preparation of zirconium-based amorphous alloy composite material coating based on the induction melting gas atomization spherical amorphous powder without crucible electrode and synchronous powder feeding comprises the following steps:

[0050] Step 1: Powder preparation and mixing:

[0051] Take Zr 50.4 Cu 28 Ni 9 al 12.3 Alloy rod 2.12kg was used as the raw material, and zirconium-based amorphous alloy high-spherical pre-alloyed powder was prepared by induction melting gas atomization without crucible electrode (induction melting gas atomization without crucible electrode), and the initial atomization gas pressure was selected as 4MPa. The power supply is 40kW, the rotation speed is 6r / min, and 1.95kg zirconium-based amorphous alloy high-spherical pre-alloyed powder is prepared, and the powder yield is about 92%. After powder making, the powder is sieved, and the powder of 45 μm-120 μm is selected, and the powder and the SiC nano powder with a diameter of 200...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com