Functional dressing and preparation method thereof

A functional, volatile organic technology, applied in adhesive dressings, non-adhesive dressings, dressings, etc., can solve the problems of inconvenient use, accelerated micro-current stimulation, etc., and achieve convenient use, improved spinning efficiency, and good biocompatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

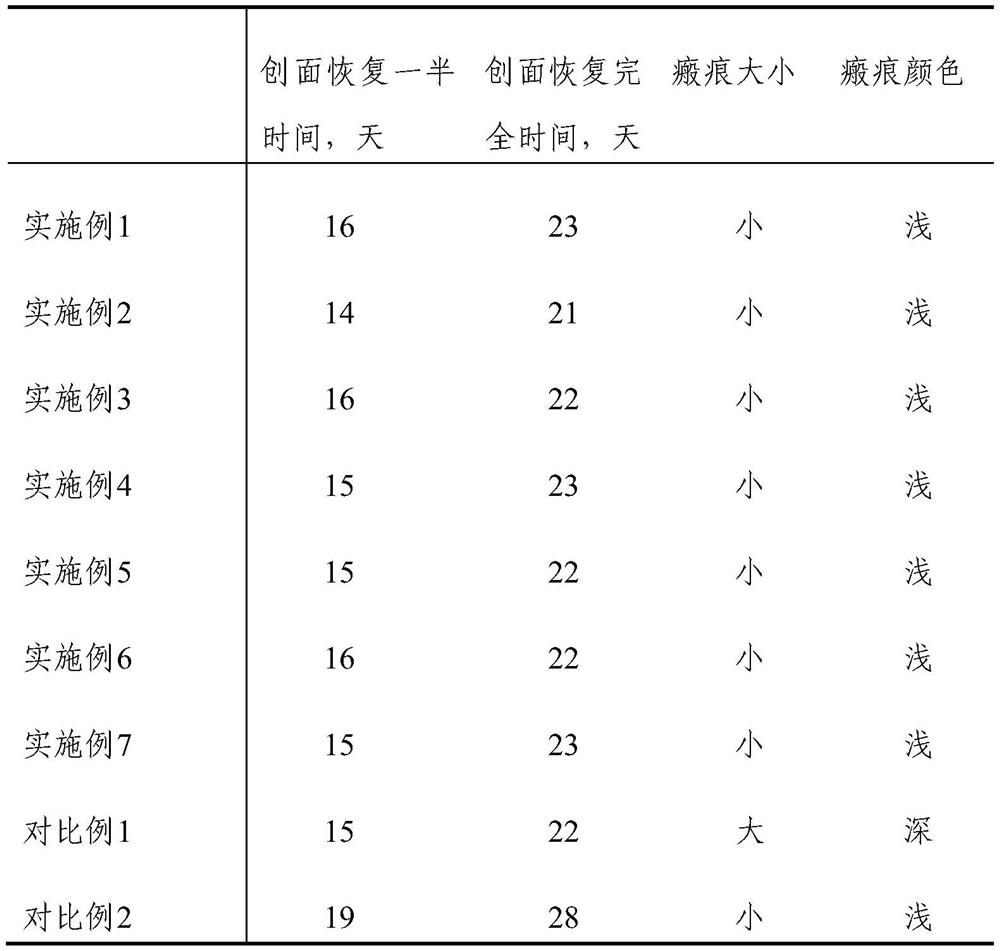

Embodiment 1

[0050] Dissolve PVDF powder (molecular weight: 550,000) in N,N-dimethylformamide with stirring and dissolving in an oil bath at 50°C to obtain a uniform and transparent solution (the first spinning solution) with a mass concentration of 25%, draw 5mL with a 10mL syringe Electrospinning is performed on the above spinning liquid, and the fiber filaments are received into a film-like structure to obtain a fiber film with a thickness of 0.08 mm. Electrospinning parameters are: spinning voltage 10kV, spinning advance speed 2mL / h, receiving distance 20cm, spinning needle inner diameter 0.8mm, spinning temperature 25°C, receiving time 2h. Liquid silicone resin (80 parts of Zhonghao Chenguang Chemical Research Institute Co., Ltd. 1053 silicone resin + 18 parts of Zhonghao Chenguang Chemical Research Institute Co., Ltd. GY209-3 hydroxyl silicone oil + 2 parts of Shandong Qufu Chemical Co., Ltd. KH550) will be used for the prepared fiber film, Tu-4 cup viscosity 68s, cured Shore A hardn...

Embodiment 2

[0052] PDMS (Jiangxi Lanxinghuo Silicone Co., Ltd. RTV108, molecular weight 1,000,000) was dissolved in tetrahydrofuran (THF) and stirred at room temperature to obtain a uniform and transparent solution (the second spinning solution) with a mass concentration of 45%. PVDF powder (molecular weight 550,000) was dissolved in N,N-dimethylformamide with stirring and dissolving in an oil bath at 50° C. to obtain a uniform and transparent solution (the first spinning solution) with a mass concentration of 30%. The prepared two polymer solutions (the first spinning solution and the second spinning solution) were mixed according to the PVDF / PDMS mass ratio of 4:1, and the mixed solution was magnetically stirred at room temperature for 2 hours to obtain a uniform and transparent spinning solution. Silk solution (blended spinning solution). 5 mL of the above-mentioned mixed spinning solution was extracted with a 10 mL syringe for electrospinning, and the fiber filaments were received int...

Embodiment 3

[0054] Dissolve PDMS (RTV108, molecular weight: 1,000,000 from Jiangxi Lanxinghuo Silicone Co., Ltd., molecular weight: 1,000,000) in THF and stir at room temperature to obtain a uniform and transparent solution with a mass concentration of 50%. Dissolve PVDF powder (molecular weight: 550,000) in N,N-di Methylformamide was stirred and dissolved in an oil bath at 50° C. to obtain a uniform and transparent solution with a mass concentration of 25%. The prepared two polymer solutions were mixed according to the PVDF / PDMS mass ratio of 5:1, and the mixed solution was magnetically stirred at room temperature for 2 hours to obtain a uniform and transparent spinning solution. 5 mL of the above-mentioned mixed spinning solution was extracted with a 10 mL syringe for electrospinning, and the fiber filaments were received into a film-like structure to obtain a blended fiber film with a thickness of 0.1 mm. Electrospinning parameters are: spinning voltage 10kV, spinning advance speed 2mL...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com