Mobile integrated dual-flow air-cooled reactor system and its working method

An air-cooled reactor, dual-process technology, applied in steam applications, machines/engines, steam engine installations, etc., can solve problems affecting reactor neutron economy, strict requirements for rotating shaft materials, reactor safety issues, etc., to reduce material performance and processing and manufacturing technical requirements, small size, and the effect of equipment redundancy and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The structure of the present invention will be described in detail below in conjunction with the drawings and specific embodiments.

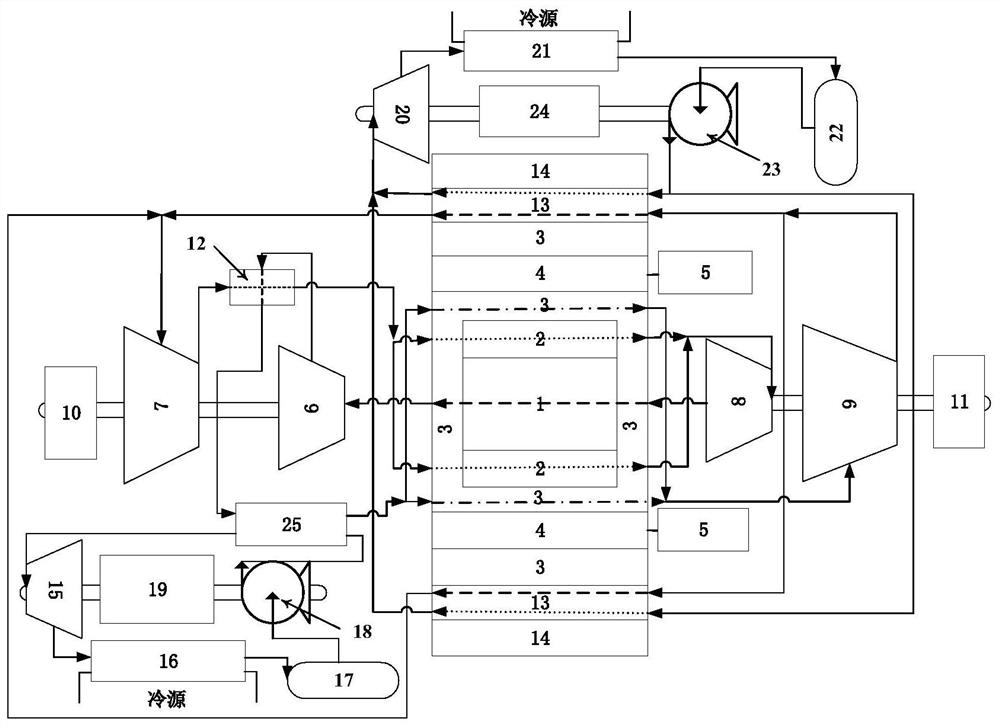

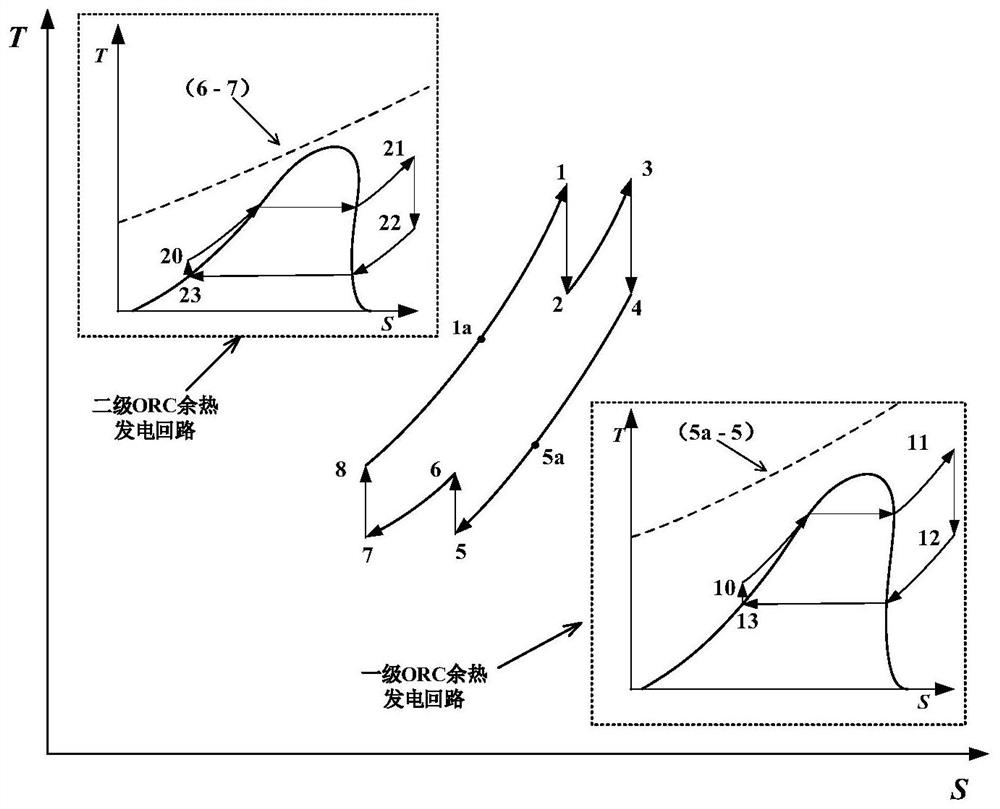

[0025] Such as figure 1 As shown, a mobile integrated double-flow air-cooled reactor system of the present invention adopts Brayton-Organic Rankine combined cycle, and the whole system includes an air-cooled reactor part, a main power generation part and an ORC waste heat power generation part, and the air-cooled reactor The part includes a reactor fuel tank, a reflective layer 3, a control drum 4, a drum driving mechanism 5, and a radiation shielding layer 14 from the inside to the outside. The reactor fuel tank is composed of an inner fuel tank 1 and an outer fuel tank 2. The inner fuel tank The outer fuel tank 2 is arranged on the periphery of the tank 1, the radially outer tank wall of the inner fuel tank 1 is closely attached to the radially inner tank wall of the outer fuel tank 2, and the inner fuel tank 1 and the outer fuel tank 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com