Low-temperature flame-retardant organic electrolyte for electric double-layer capacitor and preparation method

An electric double layer capacitor and organic electrolyte technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrolytes, etc., can solve the problems of poor safety, decreased device discharge performance, easy leakage, etc. The effect of halving the extinction time and excellent low temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

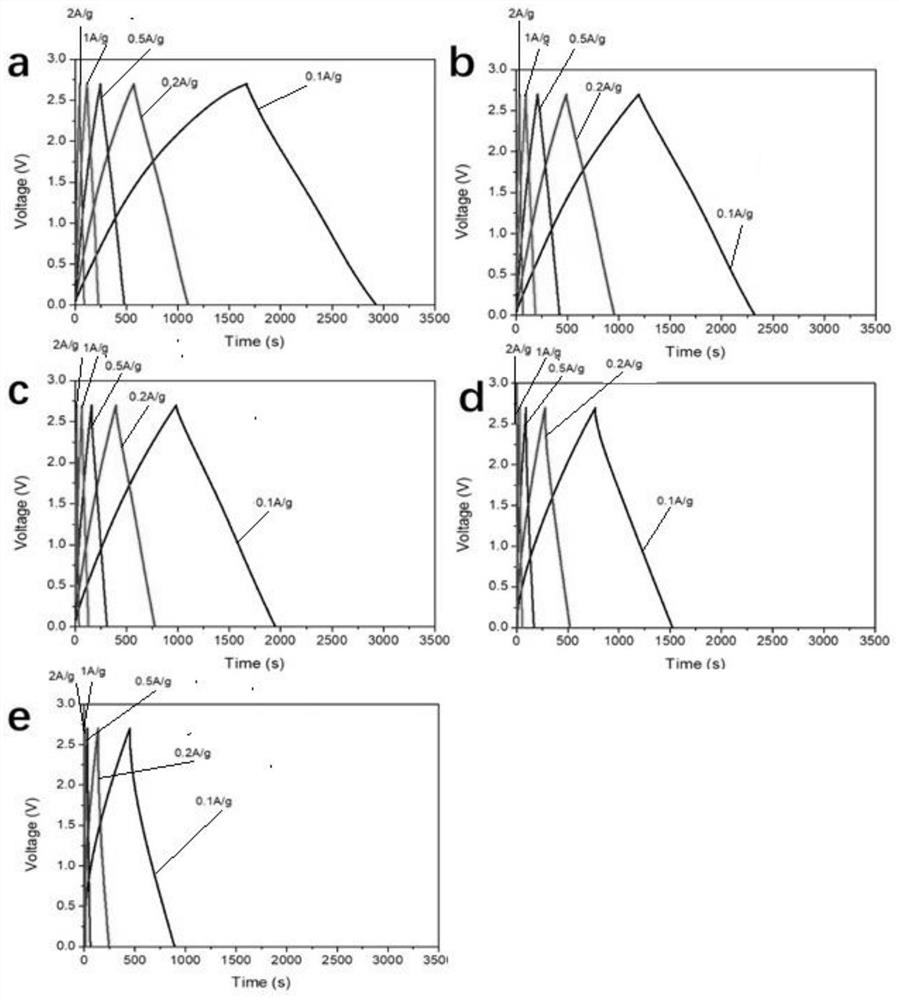

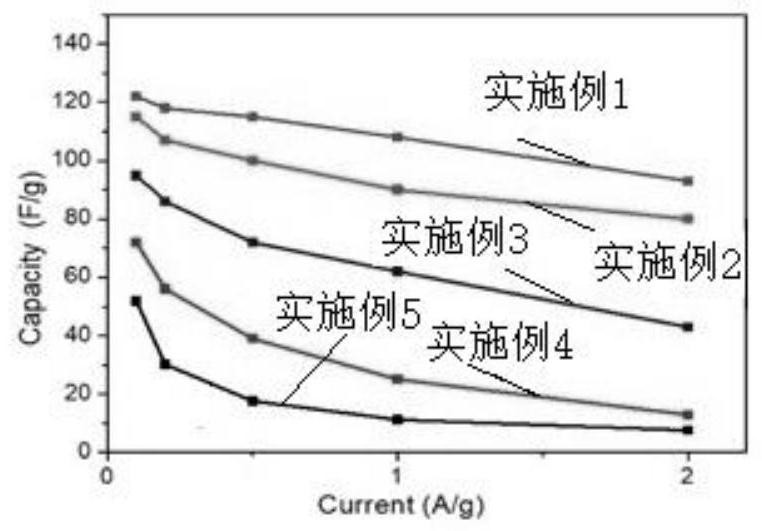

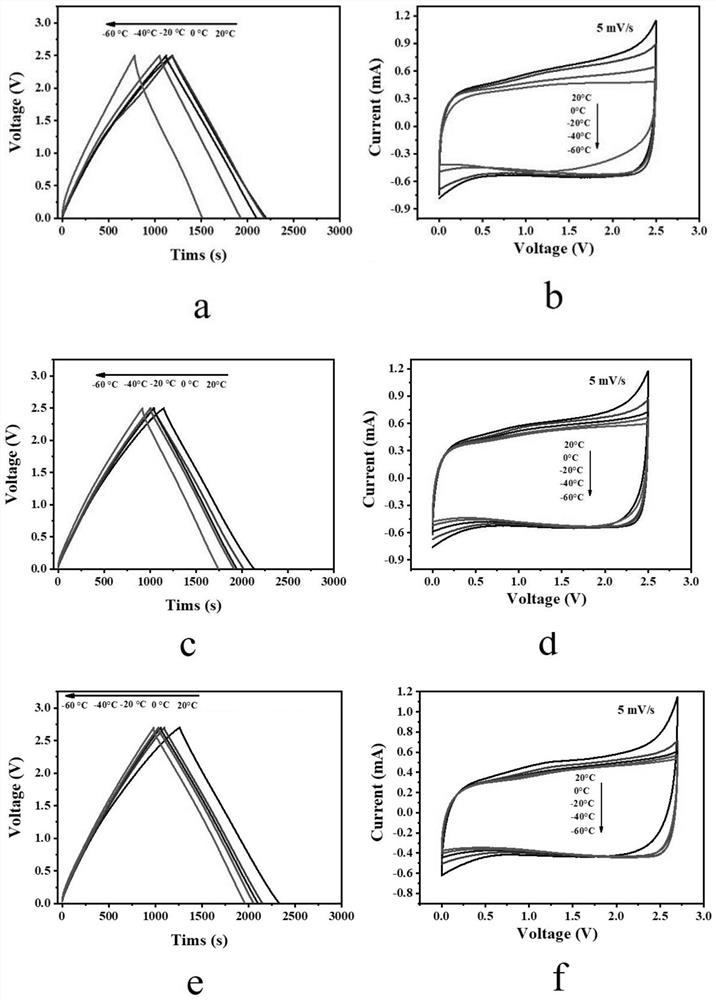

[0030] This embodiment provides a low-temperature flame-retardant organic electrolyte solution for electric double-layer capacitors, including an electrolyte and an organic solvent. The concentration of the electrolyte in the electrolyte is 0.8-1.2mol / L, wherein the organic solvent includes a main Co-solvent and flame-retardant additive, the volume ratio of the main solvent, low-temperature co-solvent and flame-retardant additive is (6~8):(0.5~2):(0.5~2);

[0031] The electrolyte is a quaternary ammonium salt, and the quaternary ammonium salt is one or more of tetraethylammonium tetrafluoroborate, triethylmethyl tetrafluoroborate, tetrafluoroborate spirocyclic ammonium salt The combination.

[0032] The main solvent is acetonitrile;

[0033] The low-temperature co-solvent is one or a combination of carbonate, γ-butyrolactone, propionate, and 1,3-dioxolane, and the carbonate is dimethyl carbonate, diethyl carbonate , ethyl methyl carbonate, dipropyl carbonate, dibutyl carbona...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com