Negative active film layer and preparation method thereof, pre-lithiation method, negative pole piece and lithium battery

A technology of active negative electrode and negative electrode plate, applied in the field of negative electrode plate and lithium battery, can solve the problems of difficult operation, low safety factor, low theoretical capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] Specifically, the application provides a method for preparing a negative electrode active film layer, which includes the following steps:

[0031] S1. Obtain molten lithium liquid.

[0032] Since impurities have a great influence on the properties of the final product obtained, specifically, the molten lithium solution is obtained by: polishing the surface of the lithium foil to remove surface impurities, placing it in a melting device protected by an inert atmosphere, and heating until molten.

[0033] Optionally, the lithium foil has a purity >99.99%.

[0034] Through the above-mentioned setting method, the interference of impurities contained in the lithium foil itself is avoided. At the same time, due to the active nature of lithium, the above-mentioned method of melting under an inert atmosphere can effectively avoid lithium from reacting with moisture and oxygen in the air during the melting process. Introduce impurities and affect the final product performance....

Embodiment 1

[0081] S1. The surface of the lithium foil is polished, placed in a melting device protected by argon (purity ≥ 99.99%), and heated to 250°C to obtain molten lithium.

[0082] S2. Slowly add fluorinated graphite powder into the liquid molten lithium at a speed of 150rpm, stir slowly to make it fully mixed, then pour it out, and use a four-sided scraper to scrape it on the upper surface of the 8μm thick copper foil, Squeegee coating with a thickness of 1.5 μm, and then place it in O 2 2 In the environment of O<0.1ppm, let it stand for 5 hours to make it form a negative electrode active film layer on the surface of the copper foil, as a pre-lithiated stable lithium-coated copper foil.

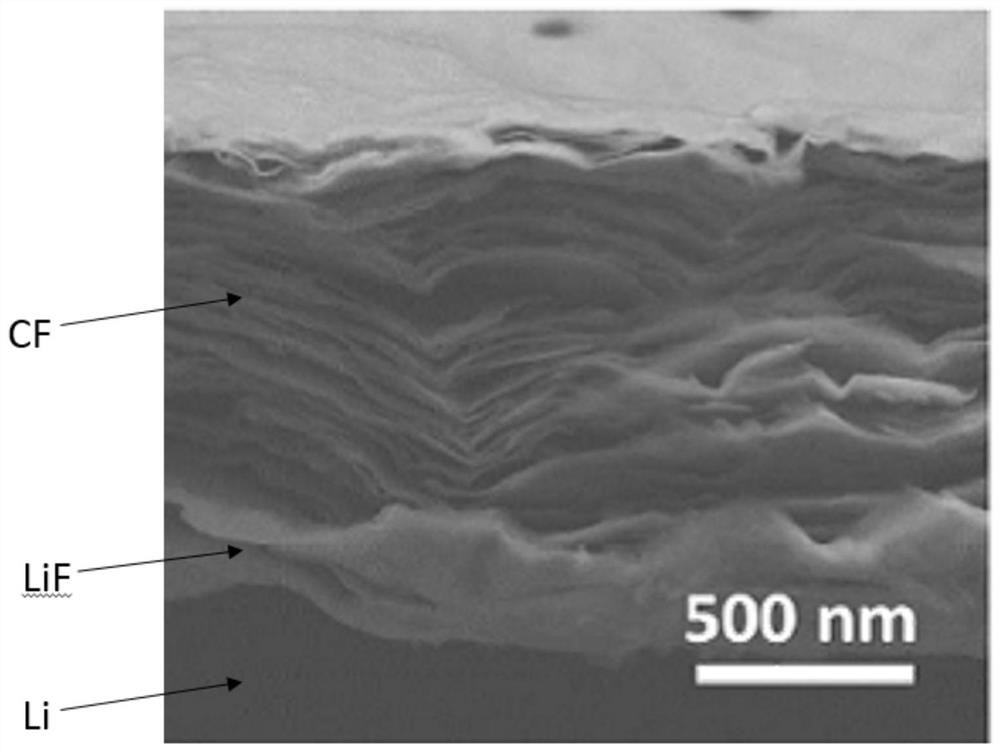

[0083] Among them, the scanning electron microscope image of the negative electrode active film layer is as follows figure 2 As shown, it can be seen that the negative electrode active film layer is a sandwich structure of CF layer-LiF layer-Li layer.

[0084] The Li layer in the negative elec...

Embodiment 2

[0086] S1. The surface of the lithium foil is polished, placed in a melting device protected by argon (purity ≥ 99.99%), and heated to 250°C to obtain molten lithium.

[0087] S2. Slowly add fluorinated graphite powder into the liquid molten lithium at a speed of 150rpm, stir slowly to make it fully mixed, then pour it out, and use a four-sided scraper to scrape it on the upper surface of the 8μm thick copper foil, Squeegee coating with a thickness of 0.5 μm, and then place it in O 2 2 In the environment of O<0.1ppm, let it stand for 5h to form a uniform negative electrode active film layer of CF layer-LiF layer-Li layer on the surface of the copper foil, as a pre-lithiated stable lithium-coated copper foil.

[0088] Wherein, the Li layer in the negative electrode active film layer is connected to the copper foil surface, the mass ratio of graphite fluoride powder to liquid molten lithium is 1:10, and the particle size and fluorocarbon ratio of graphite fluoride powder are sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com