A kind of MOF bulk porous material and its preparation method and application

A porous material and block technology, applied in the preparation of carboxylic acid nitriles, chemical instruments and methods, and the preparation of organic compounds, can solve problems such as reducing catalytic efficiency, hindering the contact between MOFs and reaction substrates, and limiting the application value of MOF materials. , to achieve the effect of simple preparation process, excellent oil absorption and catalytic performance, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

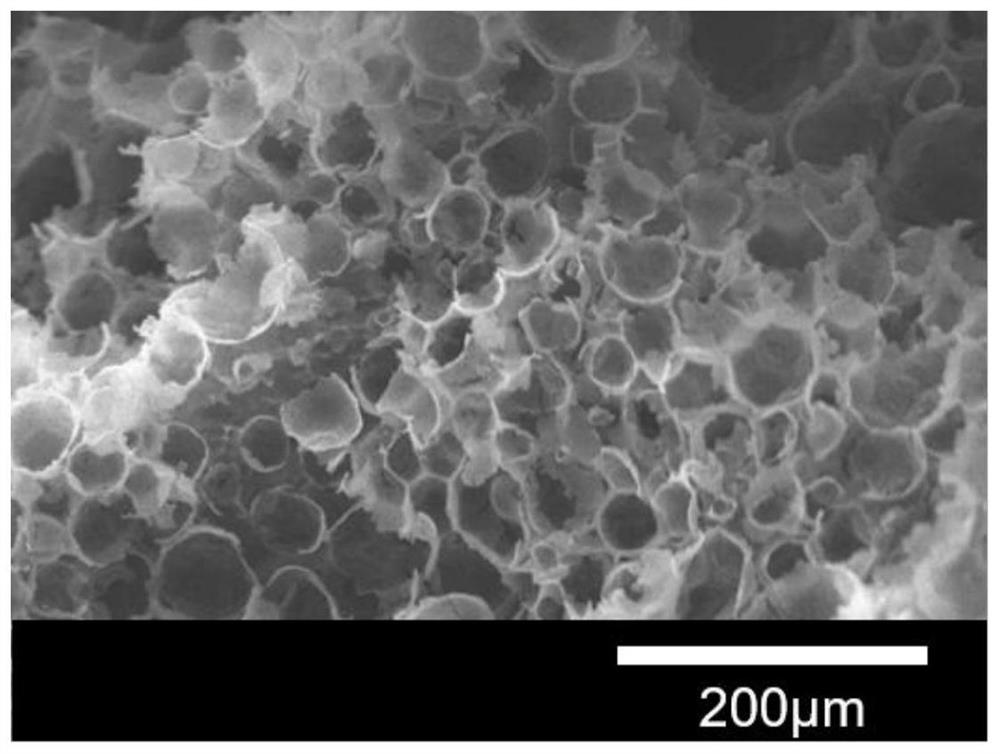

[0026] The present invention provides a kind of preparation method of MOF bulk porous material, comprises the following steps:

[0027] Mixing 2-methylimidazole, zinc nitrate hexahydrate, ZIF-8 nanoparticles and water to obtain an aqueous phase;

[0028] Using linear alkanes as the oil phase, adding the oil phase dropwise to the stirred water phase, and shearing the resulting mixture to form a high internal phase emulsion;

[0029] The high internal phase emulsion is freeze-dried to obtain MOF bulk porous material.

[0030] In the present invention, unless otherwise specified, the required preparation materials are commercially available products well known to those skilled in the art.

[0031] The invention mixes 2-methylimidazole, zinc nitrate hexahydrate, ZIF-8 nanoparticles and water to obtain the water phase. In the present invention, the preparation method of the ZIF-8 nanoparticles preferably includes the following steps: mixing 2-methylimidazole, nitric acid hexahydr...

Embodiment 1

[0048] 18.47g (0.22mol) 2-methylimidazole was dissolved in 135mL deionized water to obtain a 2-methylimidazole solution, and 1.116g (0.00375mol) zinc nitrate hexahydrate was dissolved in 15mL deionized water to obtain a zinc nitrate solution , drop the zinc nitrate solution into the 2-methylimidazole solution at room temperature, stir at 600rmp for 24h, centrifuge the resulting mixture at 10,000rmp for 5min, filter, and wash three times with deionized water to obtain ZIF -8 nanoparticles;

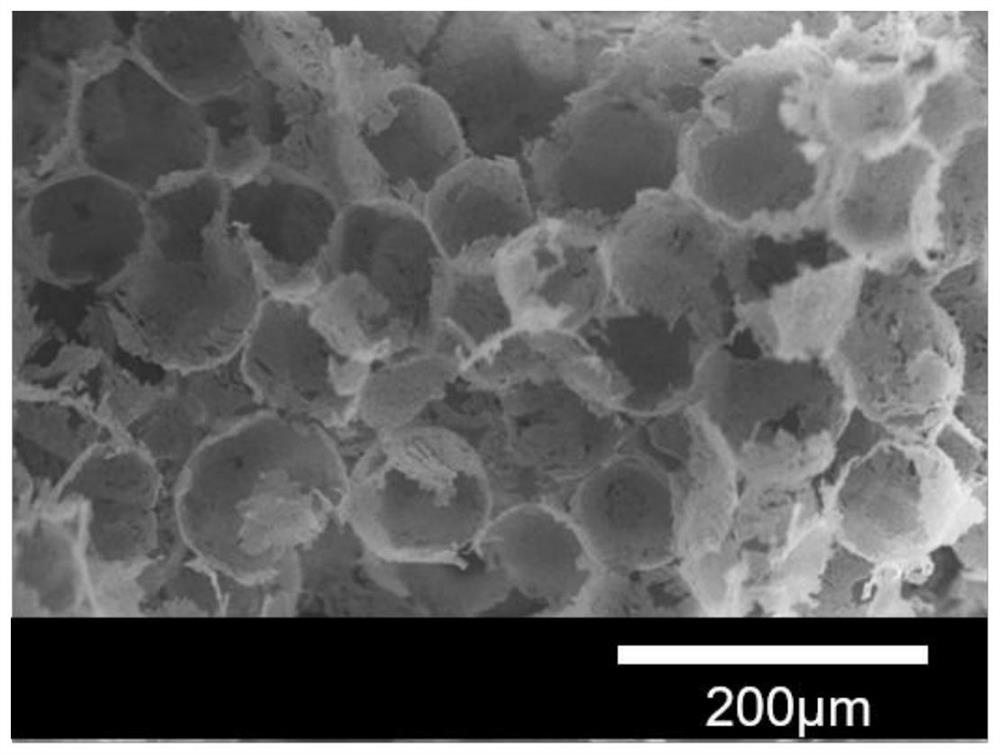

[0049] 1.23g 2-methylimidazole, 0.0744g zinc nitrate hexahydrate and 0.132g ZIF-8 nanoparticles were added to 2mL deionized water as the water phase; 12mL cyclohexane was used as the oil phase; the oil phase was added dropwise to In the water phase under stirring at 900rmp, after mixing evenly, the resulting mixed liquid was emulsified at 12000rmp for 60s using an Ultra Turrax T18 shear emulsifier to obtain a high internal phase emulsion; the high internal phase emulsion was freeze-dried to...

Embodiment 2

[0051] Adopt the ZIF-8 nanometer particle that embodiment 1 prepares;

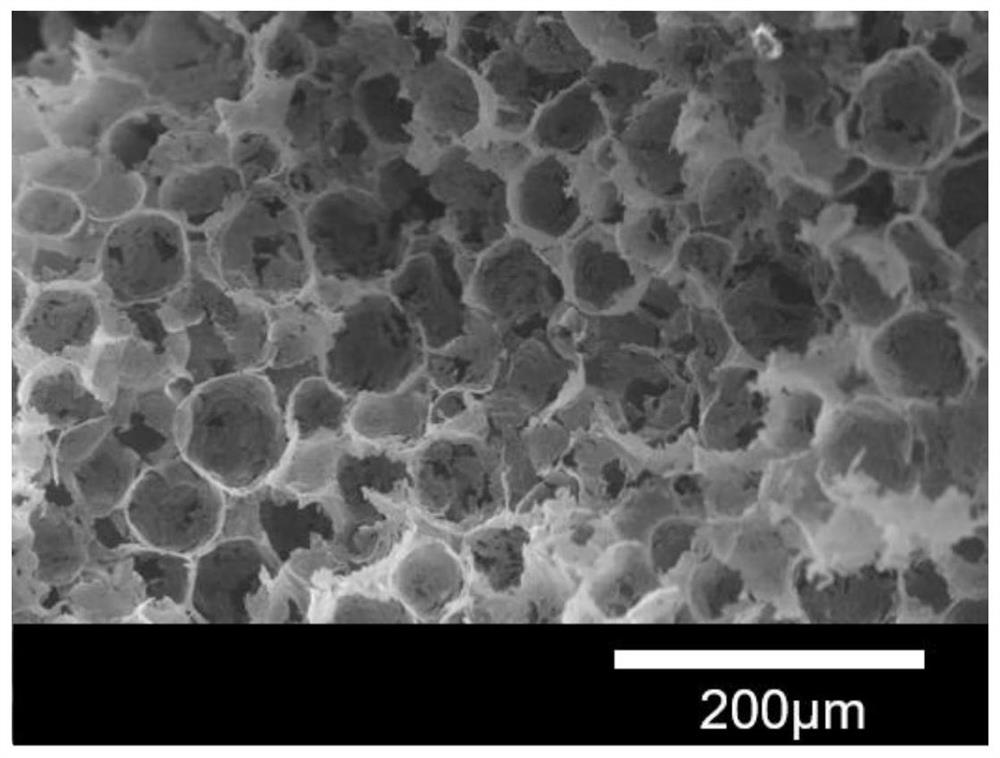

[0052] 1.23g 2-methylimidazole, 0.0744g zinc nitrate hexahydrate and 0.264g ZIF-8 nanoparticles were added to 2mL deionized water as the water phase; 12mL cyclohexane was used as the oil phase; the oil phase was added dropwise to In the water phase under stirring at 900rmp, after mixing evenly, the resulting mixed liquid was emulsified at 12000rmp for 60s using an Ultra Turrax T18 shear emulsifier to obtain a high internal phase emulsion; the high internal phase emulsion was freeze-dried to obtain MOF blocks porous material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com