Surface smoothing processing technology applied to natural stone processing treatment

A technology for stone processing and surface smoothing, which is applied to the device, coating, epoxy resin coating and other directions for coating liquid on the surface, which can solve the problem of smooth surface effect, low degree of wear resistance and scratch resistance, affecting natural stone. Use effect, surface gelatinization of decorative materials, etc., to achieve the effect of surface energy not easy to contaminate, good decorative effect, and improved gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

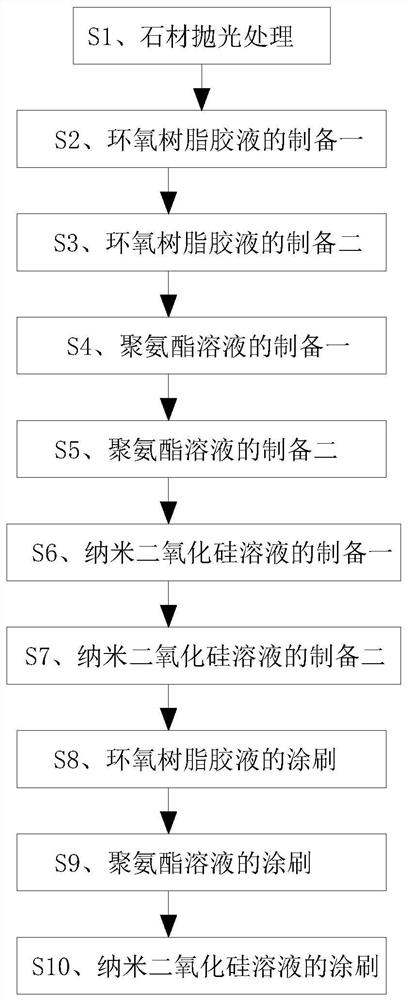

[0028] Example 1: Please refer to figure 1 , the invention discloses a surface smoothing process applied to natural stone processing comprising the following steps:

[0029] S1. Stone polishing treatment: Polish the surface of the required natural stone, clean it up after polishing, and set aside;

[0030] S2. Preparation of epoxy resin glue solution 1: Weigh the prepared raw materials in order according to parts by weight: 2 parts of epoxy resin, 10 parts of water-based polyurethane solution, 4 parts of modified chloroprene latex, 0.5 part of reactive diluent and film-forming 0.3 part of auxiliary agent;

[0031] S3, preparation two of epoxy resin glue: put the epoxy resin weighed in step S2 into agitator one, and add water-based polyurethane solution, modified chloroprene latex, acrylic emulsion and active Diluent, the active diluent in the step S2 is n-butyl glycidyl ether, after stirring evenly, add the film-forming aid, the film-forming aid in the step S3 is a mixture o...

Embodiment 2

[0039] Example 2: Please refer to figure 1 , the invention discloses a surface smoothing process applied to natural stone processing, comprising the following steps:

[0040] S1. Stone polishing treatment: Polish the surface of the required natural stone, clean it up after polishing, and set aside;

[0041] S2. Preparation of epoxy resin glue solution 1: Weigh the prepared raw materials in order according to parts by weight: 8 parts of epoxy resin, 15 parts of water-based polyurethane solution, 9 parts of modified chloroprene latex, 1.2 parts of reactive diluent and film-forming 0.7 parts of auxiliary agent;

[0042] S3, preparation two of epoxy resin glue: put the epoxy resin weighed in step S2 into agitator one, and add water-based polyurethane solution, modified chloroprene latex, acrylic emulsion and active Diluent, the active diluent in the step S2 is ethylene glycol diglycidyl ether, after stirring evenly, add the film-forming aid, the film-forming aid in the described s...

Embodiment 3

[0050] Example 3: Please refer to figure 1 , the invention discloses a surface smoothing process applied to natural stone processing, comprising the following steps:

[0051] S1. Stone polishing treatment: Polish the surface of the required natural stone, clean it up after polishing, and set aside;

[0052] S2. Preparation of epoxy resin glue solution 1: Weigh the prepared raw materials in order by weight: 15 parts of epoxy resin, 20 parts of water-based polyurethane solution, 10 parts of modified chloroprene latex, 1.5 parts of reactive diluent and film-forming 0.8 parts of auxiliary agent;

[0053] S3, preparation two of epoxy resin glue: put the epoxy resin weighed in step S2 into agitator one, and add water-based polyurethane solution, modified chloroprene latex, acrylic emulsion and active Diluent, the active diluent in the step S2 is n-butyl glycidyl ether, after stirring evenly, add the film-forming aid, the film-forming aid in the step S3 is a mixture of polyethylene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com