Double-layer composite floor and preparation method thereof

A double-layer composite and floor technology, which is applied to chemical instruments and methods, coatings, layered products, etc., can solve the problems of high material cost and low flexural strength of polyurethane sheets, achieve good surface contact, and improve laying efficiency , The effect of reducing the laying cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

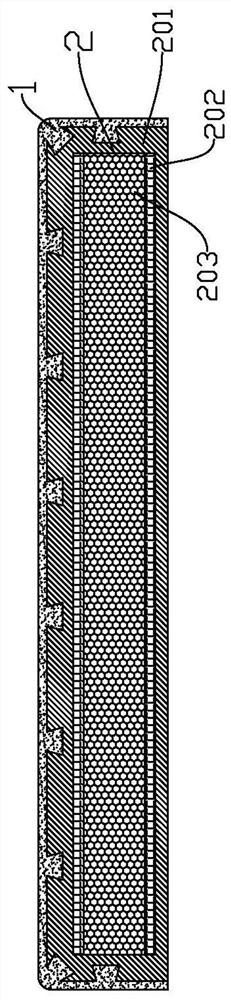

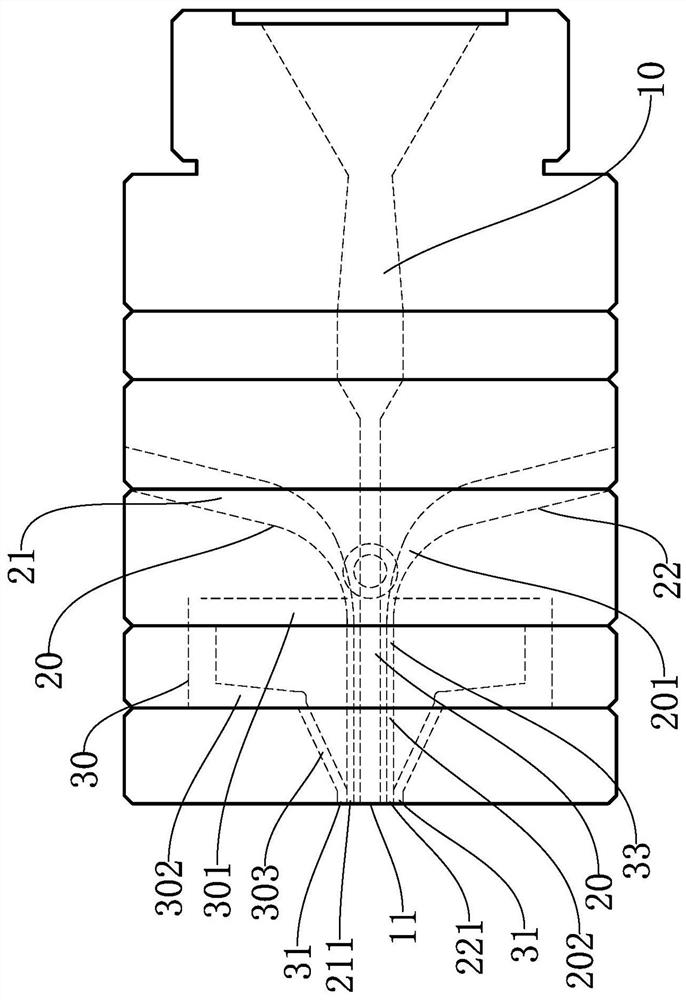

[0077] Such as figure 1 As shown, a double-layer composite floor includes a hard core layer 2 and an elastic surface layer 1 made of PU, and the elastic surface layer 1 wraps and covers the hard core layer 2 on the upper surface and the side surface of the floor.

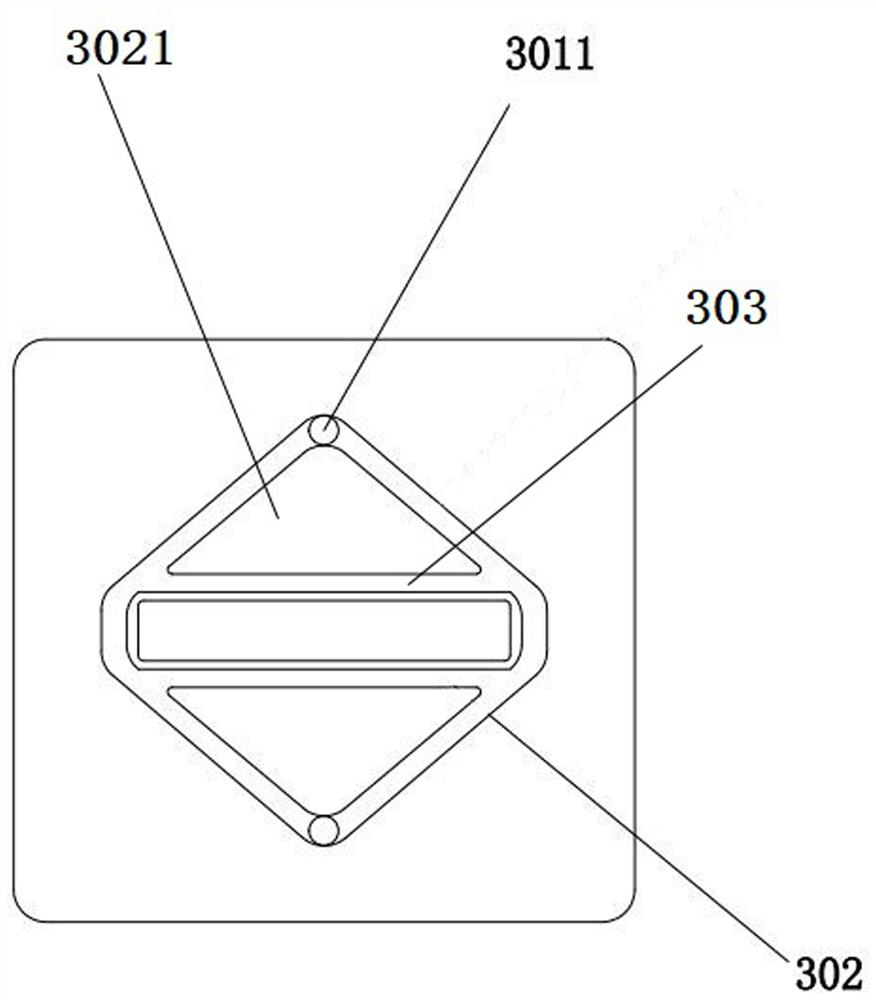

[0078] A matching structure is provided between the elastic surface layer 1 and the hard core layer 2, and the matching structure includes a plurality of unit elements formed on the surface A, a plurality of corresponding elements formed on the surface B, and a plurality of connecting units.

[0079] The surface A is the surface of the hard core layer 2 in contact with the elastic surface layer 1 , and the surface B is the surface of the elastic surface layer 1 in contact with the hard core layer 2 .

[0080] The connecting unit includes a first connecting unit arranged between two adjacent unit elements and a second connecting unit arranged between two adjacent corresponding pieces; the unit element is a section ar...

Embodiment 2

[0104] The difference from Example 1 is that the hard core layer includes a PVC hard foam core, a PVC skin layer covering the PVC hard foam core, and a co-extruded shell covering the PVC skin layer . That is, the thickness of the PVC skin layer is about 0.5 mm without the glass fiber reinforced layer; the thickness of the co-extrusion shell is about 2 mm.

[0105] The preparation method of hard core layer is as follows:

[0106] After the PVC foam material is fully mixed (PVC resin 100kg, calcium carbonate 50kg, stearic acid 0.5kg, magnesium stearate 0.5kg, calcium zinc stabilizer 5kg, AC foaming agent 1kg, zinc oxide 0.5kg, mix at high speed Mix in the machine for 15 minutes, the mixing temperature is 120°C, and then put it into the cold mixer to cool to 30°C), and extrude from the die orifice through the main extruder;

[0107] At the same time, the second raw material (PVC resin 100kg, glass hollow microspheres 20kg, calcium carbonate 50kg, magnesium stearate 2.0kg) that ...

Embodiment 3

[0111] The difference from the first embodiment is that the hard core layer is a preformed aluminum alloy profile. The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com