Method for rapidly degrading organic pollutants in water

A technology of organic pollutants and rapid degradation, applied in the field of environmental treatment, can solve the problems of high cost, restricting large-scale popularization and application, low efficiency of composite catalysts, etc., achieve long active life, solve poor catalyst activity and stability, prevent The effect of sintering and bleeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

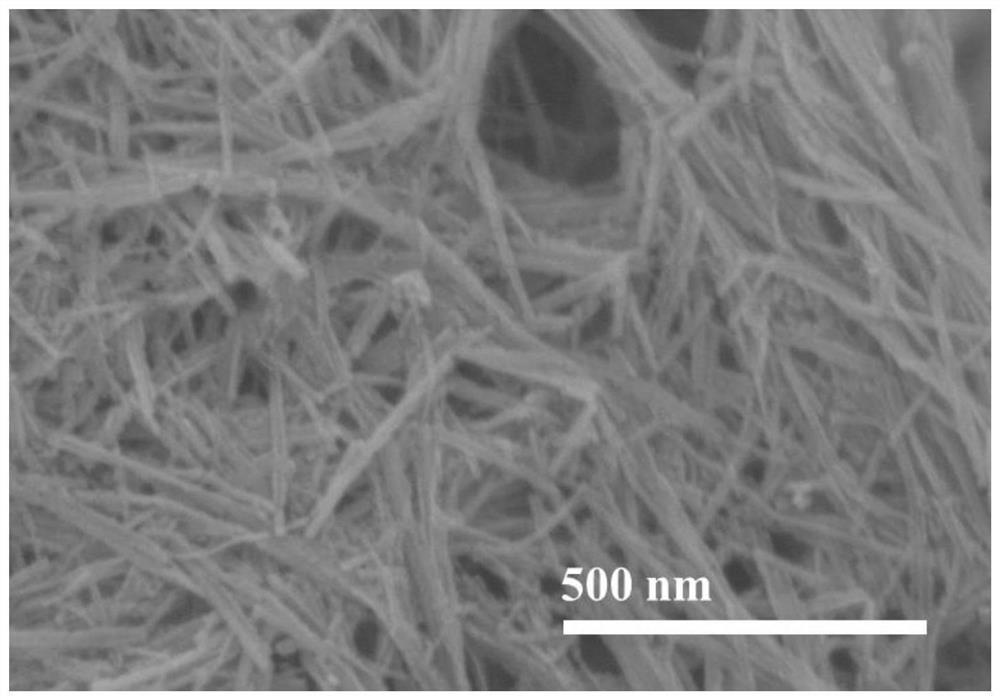

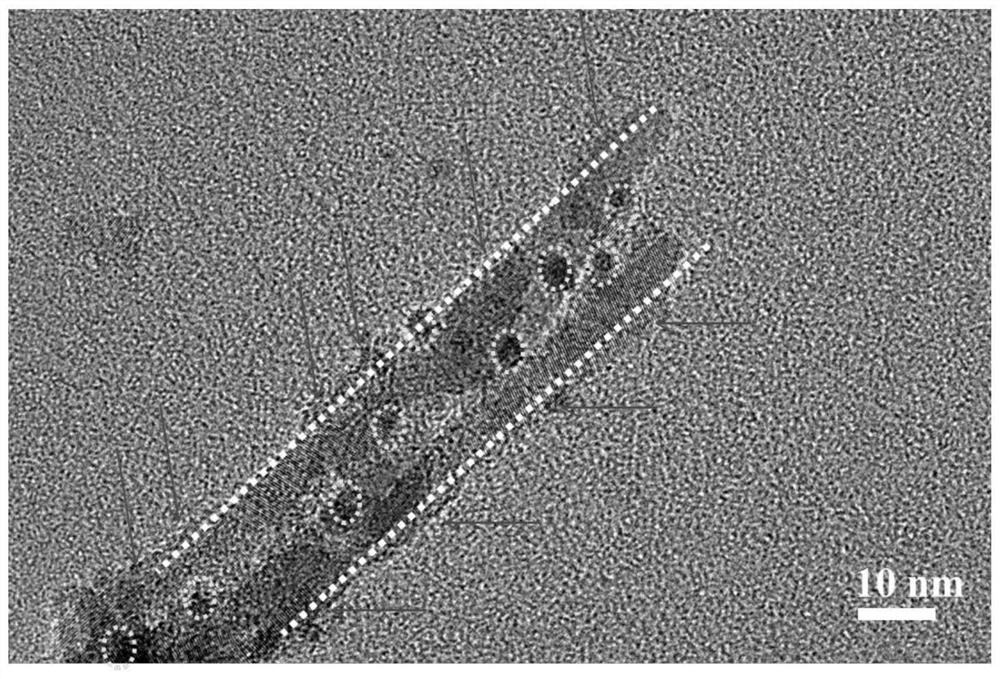

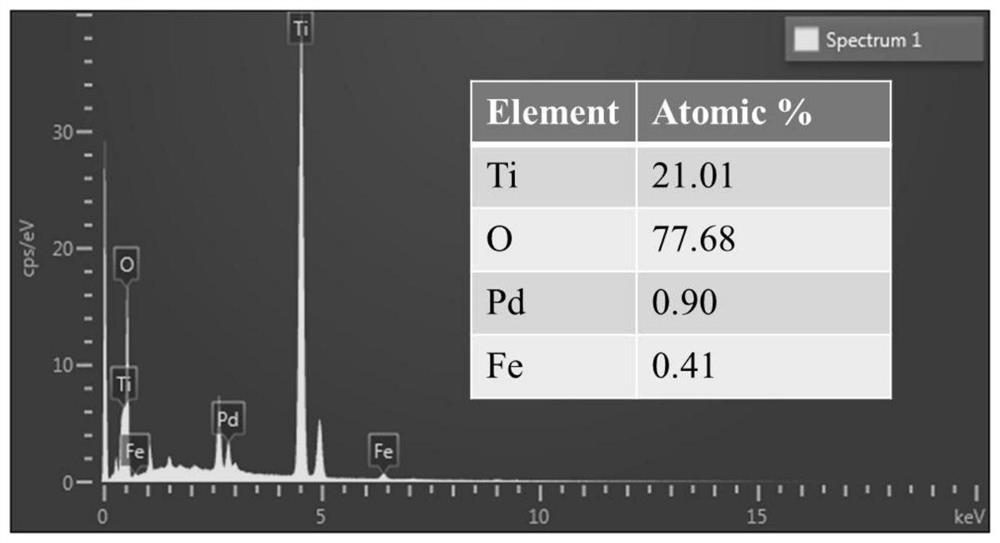

[0025] Embodiment 1: Preparation and characterization of titanium dioxide nanotube-confined palladium catalyst modified by iron oxide:

[0026] The first step, 6 gram titanium dioxide powders join in the polytetrafluoroethylene flask that 200 milliliters of 10mol / L sodium hydroxide solutions are housed, stirred and reacted at 110 ℃ for 48 hours. Then, after the reaction solution was cooled to room temperature, it was washed several times with water, and then the solid was soaked with 0.1mol / L HCl and washed several times with water until the pH was 7. After drying in an oven, the titanium dioxide nanotubes were obtained by calcining in an air atmosphere at 250° C. for 2 hours in a muffle furnace.

[0027] In the second step, 3.3ml of palladium chloride ethanol solution (1.0g / 100ml) was slowly mixed with titanium dioxide nanotubes, and after stirring for 30 minutes, at -0.03~-0.1Mpa, at room temperature, ultrasonically assisted the noble metal Pd Embedded in TiO nanotubes, the...

Embodiment 2

[0029] Embodiment 2: be that the methyl orange aqueous solution of 20ppm is mixed with the ferric oxide modified titanium dioxide nanotube confined palladium catalyst prepared in embodiment 1, add a small amount of H subsequently 2 o 2 , after 30 minutes of adsorption in the absence of light, quickly put the visible light source into the reaction device, start timing, magnetically stir during the reaction, and take samples, filter and measure the absorbance, and calculate the degradation rate of methyl orange. The results are shown in figure 2 , it can be seen that the catalyst system of the present invention can reach a degradation rate of more than 90% within 10 minutes.

Embodiment 3

[0031] Embodiment 3: Operating condition is identical with embodiment 2, and the initial concentration of methyl orange is adjusted to 100ppm, measures the degradation rate of methyl orange under the high concentration condition as a function of time, and the results are shown in Figure 4 , it can be seen that the catalytic system of the present invention can also achieve a faster degradation rate for high-concentration pollutants.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com