Catecholamine-modified cellulose material as well as preparation method and application thereof in filter membrane

A catecholamine and cellulose technology, applied in the field of membrane separation, can solve the problems of low water flux and anti-pollution performance, and achieve the effects of increasing the difficulty of adsorption, being easy to degrade, and not easy to be hydrolyzed and lost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] Another embodiment of the present invention provides a method for preparing a catecholamine-modified cellulose material as described above, comprising the following steps:

[0061] S1, using sodium periodate to oxidize cellulose molecules to prepare dialdehyde-based cellulose;

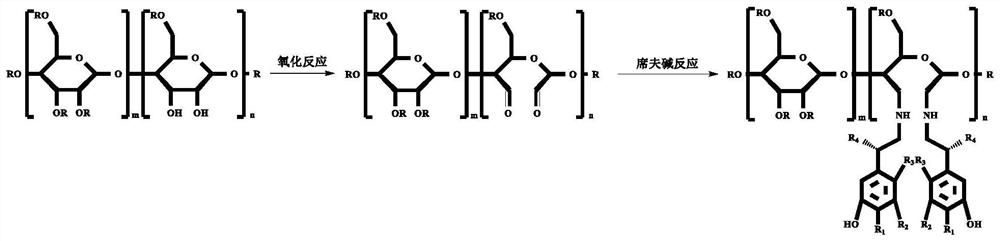

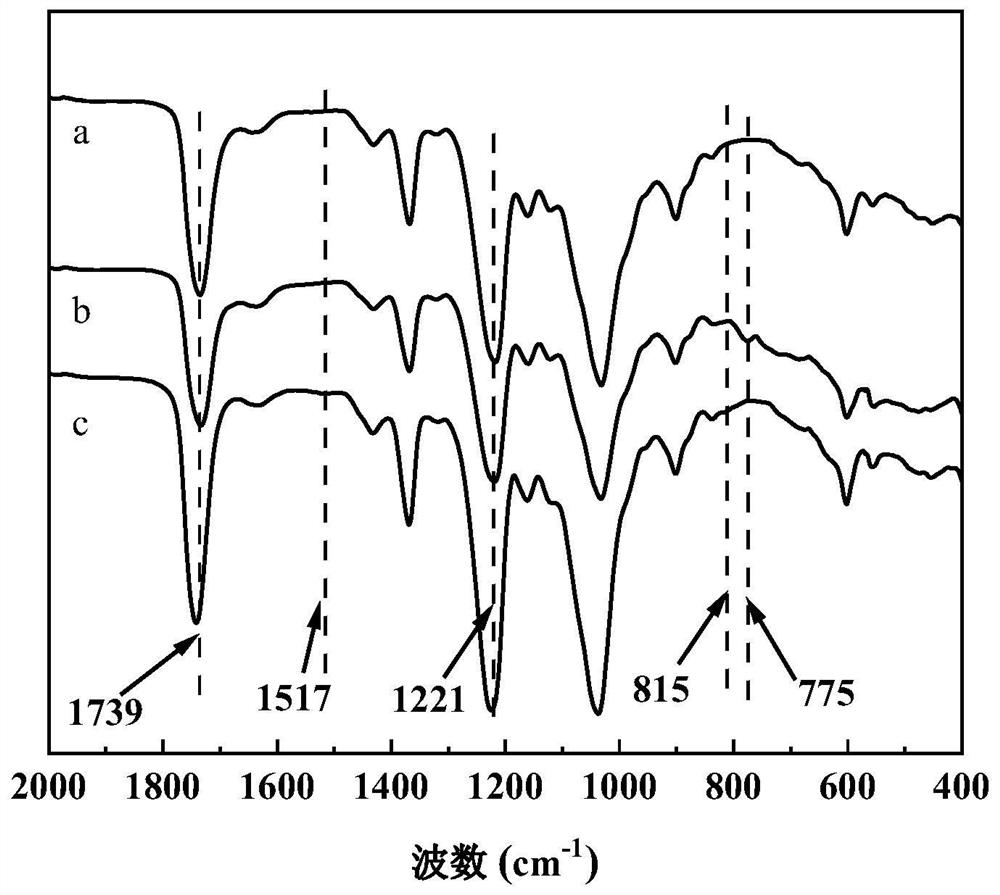

[0062] S2. Add the dialdehyde-based cellulose and the catecholamine modifier into an organic solvent and mix evenly. The terminal of the catecholamine modifier contains an amino group, and the catecholamine modifier is connected to the branching onto the dialdehyde-based cellulose to obtain a polymer, and then adding a reducing agent to react, and after the reaction, separate and obtain a catecholamine-modified cellulose material. The reaction mechanism is as follows: firstly, the selective oxidant-sodium periodate selectively oxidizes the hydroxyl groups at the 2 and 3 positions of cellulose to generate dialdehyde-based cellulose, which leads to the destruction of the main chain structure of ce...

Embodiment 1

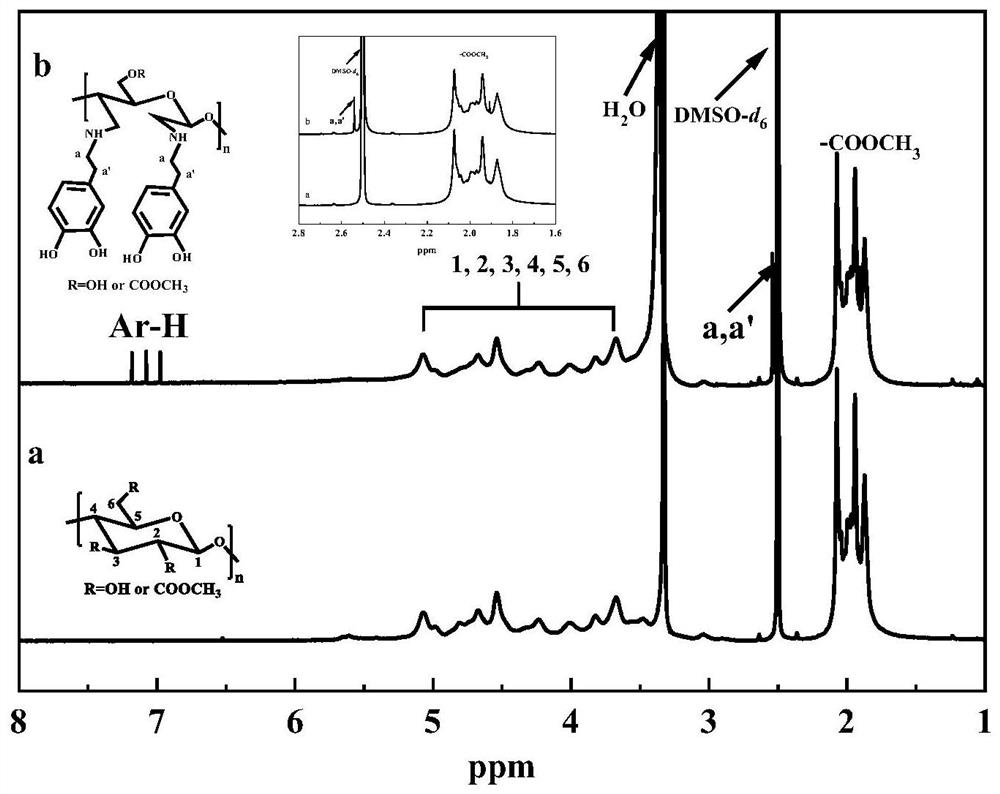

[0082] Embodiment 1 cellulose acetate grafted dopamine hydrochloride

[0083] A catecholamine-modified cellulose material, prepared by grafting catecholamine-based modifiers on cellulose acetate, the catecholamine-based modifier is dopamine hydrochloride, and the chemical structure of the catecholamine-modified cellulose-based materials is generally The formula is shown in formula (II):

[0084]

[0085] In formula (II), R is H or COCH 3 ; m is 70-90%, n is 10-30%, and m+n=100%.

[0086] The preparation method of the catecholamine modified cellulose material comprises the following steps:

[0087] S1. Dissolve 15 g of cellulose acetate in 300 mL of distilled water to obtain a cellulose acetate solution. Under the protection of an inert gas and avoid light, add 15 g of sodium periodate to the cellulose acetate solution, and heat to a temperature of 45° C. for 6 hours. Then add 75mL of ethylene glycol and react for 0.5h to obtain dialdehyde-based cellulose. The dialdehyde-...

Embodiment 2

[0091] Embodiment 2 cellulose acetate graft 5-hydroxyl dopamine

[0092] A catecholamine-modified cellulose-based material, prepared by grafting catecholamine-based modifiers on cellulose acetate, the catecholamine-based modifiers being 5-hydroxydopamine, the chemical composition of the catecholamine-based modified cellulose-based materials The general structural formula is as shown in formula (III):

[0093]

[0094] In formula (III), R is H or COCH 3 ; m is 70-90%, n is 10-30%, and m+n=100%.

[0095] The preparation method of the catecholamine-modified cellulose material is basically the same as that of Example 1, except that in step S1, 10 g of sodium periodate is added to the cellulose acetate solution, and heated to 45° C. for 4 hours. In step S2, 3 g of dialdehyde cellulose and 1 g of 5-hydroxydopamine were added to 30 mL of N,N-dimethylacetamide and mixed evenly.

[0096] In this example, it is calculated based on the molar ratio of the aldehyde group of dialdehyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Protein adsorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com