Cooling liquid for internal combustion engine, and preparation method and application of cooling liquid

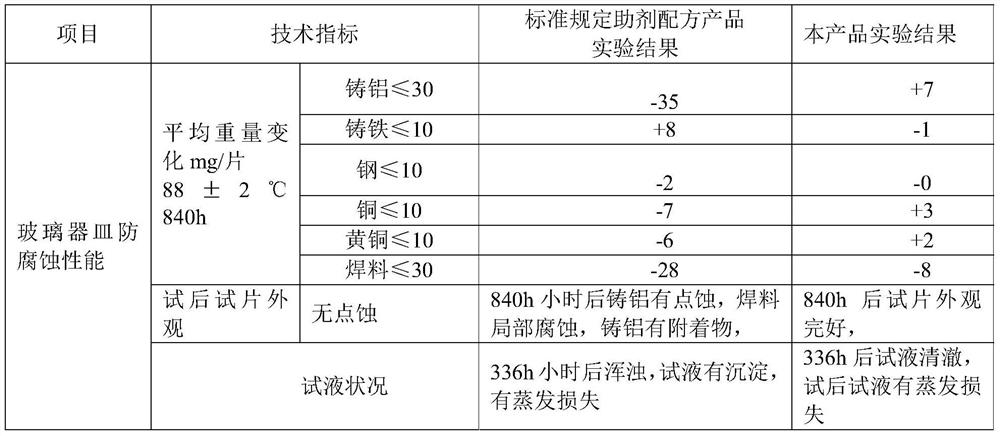

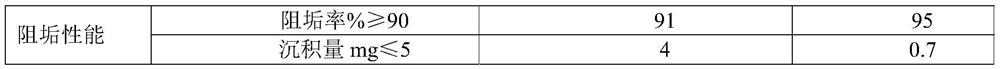

A technology for cooling liquid and internal combustion engine, applied in the field of cooling liquid, can solve the problems of corrosion, precipitation, turbidity of cooling liquid, etc., and achieve the effects of excellent cost performance, long service life, and small weight loss of the test piece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The second aspect of the present invention provides a method for preparing the aforementioned cooling liquid, wherein the method includes:

[0038] (1) Water, inorganic salt and copper bactericidal corrosion inhibitor are carried out the first mixing to obtain the first mixture;

[0039] (2) The first mixture is sequentially contacted with benzoic acid, sebacic acid, p-nitrobenzoic acid and undecanedioic acid to obtain a second mixture;

[0040] (3) The second mixture is mixed with the dispersant for the third time to obtain a cooling liquid.

[0041] According to the present invention, in step (1), water, inorganic salt and copper bactericidal corrosion inhibitor can be dissolved in glycol, and the first mixture formed is a transparent solution. In addition, in step (1), the pH value of the first mixture is above 8, preferably 8.0-8.5, within this pH range, it has a relatively good protective effect on various metals, and the pH value is too high , It is easy to caus...

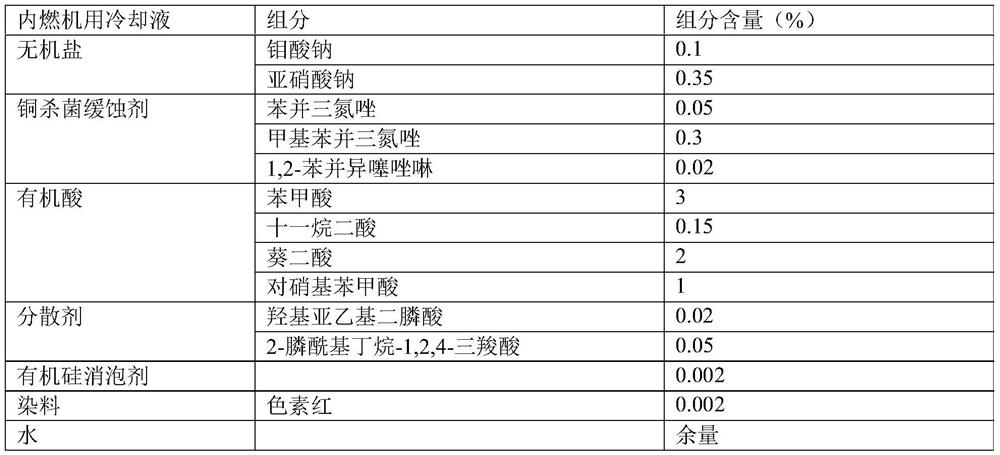

Embodiment 1

[0053] This example is used to illustrate the coolant for an internal combustion engine of the present invention.

[0054] Prepare 1000kg summer internal combustion engine coolant:

[0055] Pour 900kg of deionized water into the reaction kettle, then add 1kg of weighed sodium molybdate, 3.5kg of sodium nitrite, 0.5kg of benzotriazole, 3kg of methylbenzotriazole, 1,2-benzene 0.2 kg of diisothiazoline was stirred and heated to dissolve, and the temperature was controlled at 60° C. for 30 minutes.

[0056] Then add 30kg of benzoic acid, 1.5kg of undecanedibasic acid, 20kg of sebacic acid, and 10kg of p-nitrobenzoic acid. At the same time, add an appropriate amount of alkali potassium hydroxide, dissolve and transparent under stirring conditions, adjust the pH value to 8.5, and keep the temperature Neutralize at 60°C for about 3 hours until a transparent and uniform solution is formed;

[0057] Then add 0.2 kg of hydroxyethylidene diphosphonic acid (HEDP) and 0.5 kg of 2-phospho...

Embodiment 2

[0067] This example is used to illustrate the coolant for an internal combustion engine of the present invention.

[0068] Preparation of 1000kg winter direct-use coolant at -25°C:

[0069] Pour 410kg ethylene glycol and 400kg deionized water into the reactor, then add 2kg of weighed sodium molybdate, 3kg of sodium nitrite, 3kg of benzotriazole, 0.5kg of methylbenzotriazole, 1, 1kg of 2-benzisothiazoline was stirred and heated to dissolve, and the temperature was controlled at 60°C for 30 minutes.

[0070] Add benzoic acid 20kg again, undecanedibasic acid 2.25kg, sebacic acid 16.7kg, p-nitrobenzoic acid 9kg, add appropriate amount of alkali potassium hydroxide simultaneously, mediation pH value is 8 after dissolving transparently under stirring condition, keeps Neutralize for about 2-3 hours at a temperature of 60°C until a transparent and uniform solution is formed;

[0071] Then add 0.5 kg of hydroxyethylidene diphosphonic acid (HEDP) and 0.2 kg of 2-phosphonobutane-1,2,4-tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com