Negative pole piece of zinc secondary battery as well as preparation method and application of negative pole piece

A technology of negative pole piece and secondary battery, applied in battery electrodes, alkaline storage battery electrodes, alkaline storage batteries, etc., can solve the problems of increased cost, harsh production conditions, reduced electrode polarization, etc., to improve cycle performance and safety properties, simple preparation method, and the effect of inhibiting side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

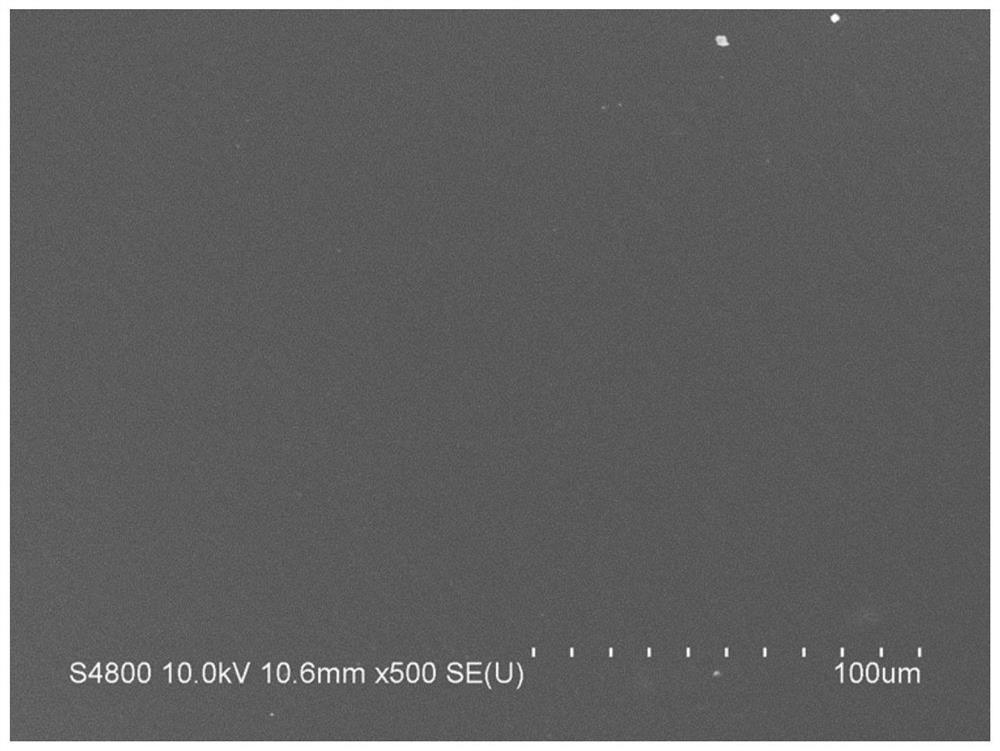

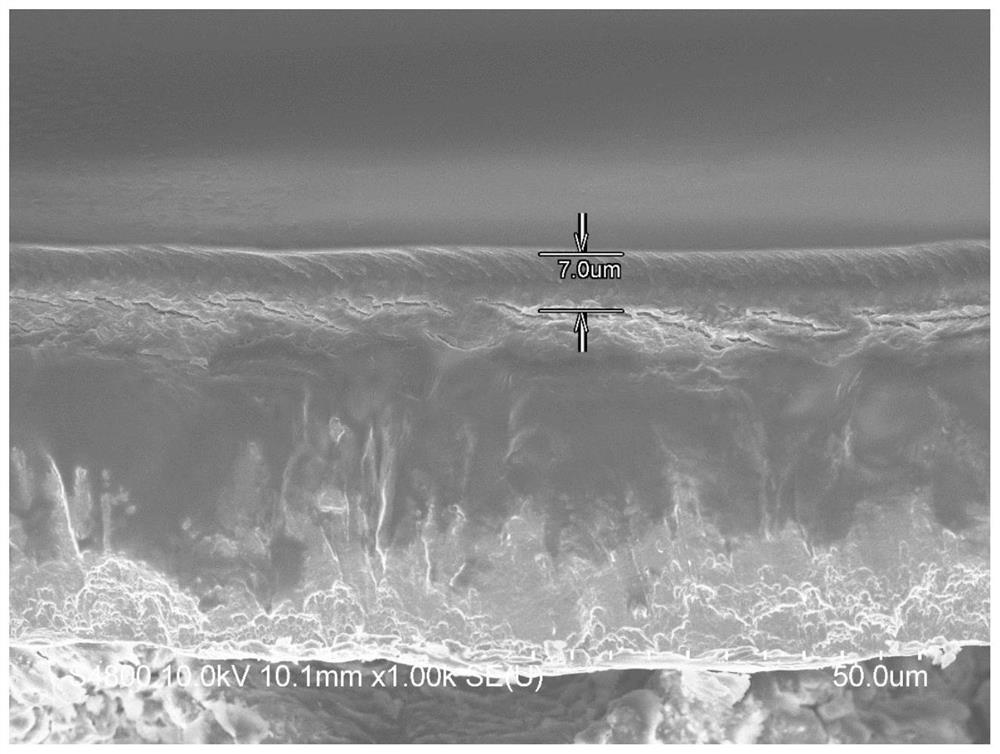

[0050] The present embodiment provides a negative electrode sheet of a zinc secondary battery, the negative electrode sheet includes a zinc sheet and a protective layer arranged on the surface of the zinc sheet; the protective layer includes a chitosan hydrogel film and is dispersed in Zinc bistrifluoromethylsulfonylimide in a hydrogel film with a protective layer of 7 μm in thickness.

[0051] The preparation method of the negative electrode sheet is as follows:

[0052] First take quantitative bistrifluoromethylsulfonylimide zinc and chitosan powder with analytical balance, join in the dilute solution (volume ratio, formic acid: water=1:100) of formic acid, be configured to contain 20mg / mL Chitosan, the gel of 0.05mol / L bistrifluoromethylsulfonylimide zinc, placed on a magnetic stirrer and stirred for 30min to promote the dissolution of chitosan, to obtain a hydrogel; pipette the hydrogel Glue on the zinc sheet, and then use a four-sided preparation device with a set thickn...

Embodiment 2

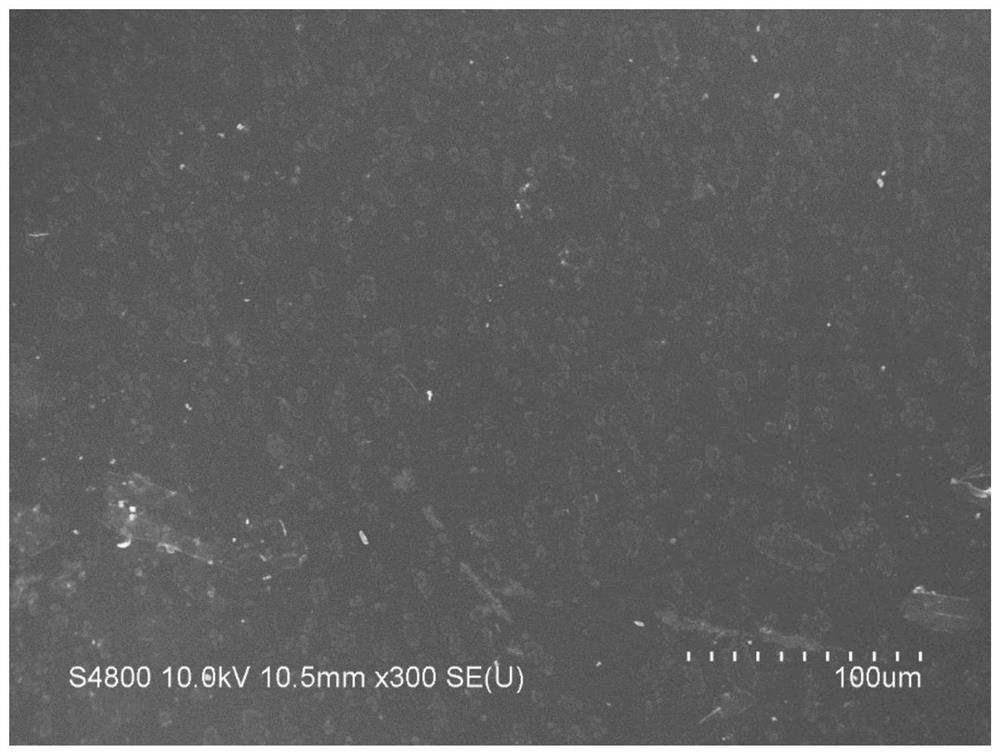

[0055] This embodiment provides a negative pole piece of a zinc secondary battery, which differs from Example 1 only in that the zinc salt in the protective layer is zinc bistrifluoromethanesulfonate; other materials, dosages and preparation methods are the same as those in Example 1. Example 1 is the same.

Embodiment 3

[0057] The present embodiment provides a negative electrode sheet of a zinc secondary battery, the negative electrode sheet includes a zinc sheet and a protective layer arranged on the surface of the substrate; the protective layer includes a chitosan hydrogel film and is dispersed in Two zinc trifluoromethylsulfonylimides in the hydrogel film, the thickness of the protective layer is 7 μm; the difference between its preparation method and Example 1 is that the mass concentration of chitosan in the hydrogel is 30mg / mL .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com