Carbon aerogel microspheres for adsorbing carbonyl sulfide and mercury and preparation method thereof

A technology of carbon aerogel and carbonyl sulfide, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems that desulfurizers do not have good renewable performance and are not suitable for high space velocity conditions, and achieve resource regeneration , high removal efficiency, clean and efficient preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

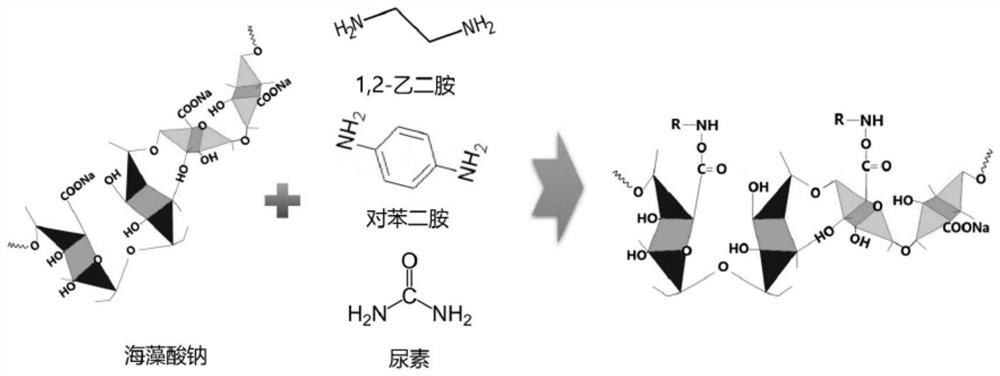

[0042] This example provides a method for preparing a nitrogen-doped modified carbon airgel material for synergistic removal of carbonyl sulfide and mercury in natural gas. The carbon airgel material is made of sodium alginate after nitrogen doping The porous high specific surface area carbon material is a carrier, loaded active metal Sn-Cu; Described method is to carry out as follows:

[0043] (1) Dissolve 2g of sodium alginate completely in 100ml of deionized water. Add 1g of urea and configured Sn to the mixture 4+ 、Cu 2+ Nitrate solution, stirred at 60°C for 6h to obtain a nitrogen-doped hydrogel loaded with metal ions;

[0044] (2) The hydrogel obtained above was rinsed with deionized water for 6 times and then placed in a freeze dryer, dried at -30°C for 24 hours to obtain an airgel, and then the obtained airgel was placed in a tube furnace at 100% N 2 The metal oxide-supported nitrogen-doped carbon airgel adsorption material was prepared by carbonization at 700°C (h...

Embodiment 2

[0051] The difference between this embodiment and embodiment 1 is that the carbonization temperature in step (2) is 900°C.

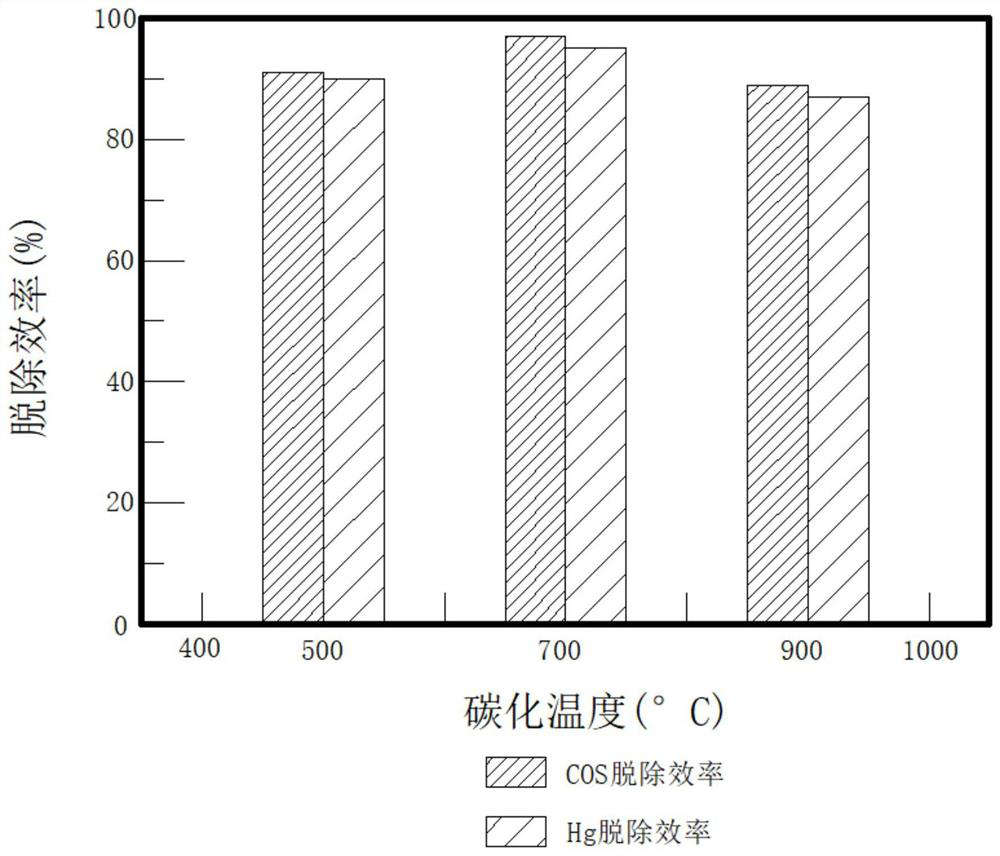

[0052] The COS and Hg removal activity evaluation experiments were carried out on the carbon airgel material prepared in this example. The experimental results show that the removal efficiency of COS can reach 89%, and the removal efficiency of Hg can reach 87%.

Embodiment 3

[0054] The difference between this embodiment and embodiment 1 is that the carbonization temperature in step (2) is 500°C.

[0055] The COS and Hg removal activity evaluation experiments were carried out on the carbon airgel material prepared in this example. The experimental results show that the removal efficiency of COS can reach 91%, and the removal efficiency of Hg can reach 90%.

[0056] Such as figure 1 As shown, it can be seen from Examples 1 to 3 that the carbonization temperature of the present invention should be controlled at 700 ° C during the preparation of carbon airgel materials, and different carbonization temperatures play an important role in the formation of the carbon material pore structure during the preparation of coal tar materials. The quality of the pore structure of the material is closely related to the subsequent metal loading, which ultimately affects the efficiency of its catalyst for synergistic removal of COS and Hg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com