Hydroxyapatite and preparation method thereof

A technology of hydroxyapatite and aqueous solution, which is applied in the field of biomedicine, can solve the problems of limited calcium salt reagents and the inability to meet the clinical needs of hydroxyapatite, and achieve pollution problems, good social and economic benefits, and a wide range of sources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

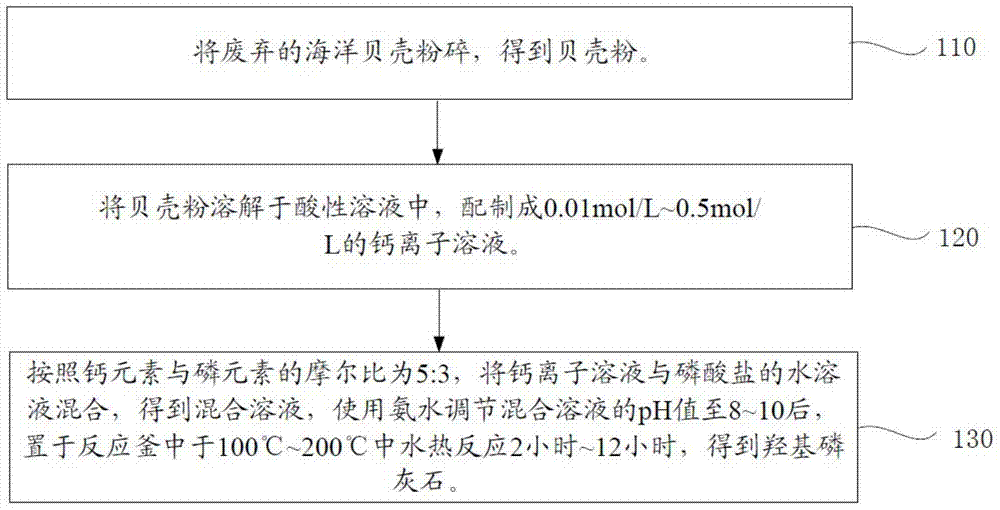

[0026] Such as figure 1 Shown, the preparation method of the hydroxyapatite of one embodiment, comprises the following steps:

[0027] Step S110: Pulverize discarded marine shells to obtain shell powder.

[0028] Among them, the main component of the shell is calcium carbonate, and the source of the shell is abundant and the price is low. Using discarded marine shells as raw materials, making full use of resources, is very environmentally friendly and in line with sustainable development strategies.

[0029] Wherein, the discarded marine shells may be oyster shells, clam shells, abalone shells, scallop shells or mussel shells.

[0030] Preferably, before the discarded marine shells are crushed, the step of cleaning and drying the discarded marine shells is also included: the discarded marine shells are soaked in an aqueous solution of 5% sodium hypochlorite by mass percentage, and then deionized Rinse with water, then dry. The organic matter in the shells is removed by imm...

Embodiment 1

[0049] The preparation method of the hydroxyapatite of the present embodiment is as follows:

[0050](1) Soak discarded oyster shells in an aqueous solution of 5% sodium hypochlorite for 1 hour, then wash them with deionized water for 3 times, and then air dry them naturally. The oyster shell is crushed mechanically to obtain the oyster shell powder.

[0051] (2) Pass the oyster shell powder through a 400-mesh sieve, then weigh 10 g of oyster shell powder and dissolve it in 1 L of 0.2 mol / L nitric acid aqueous solution, place it on a magnetic stirrer and stir for 10 minutes to obtain 0.1 mol / L Calcium ion solution.

[0052] (3) Weigh 13.2 g of diamine hydrogen phosphate, dissolve it in 500 mL of deionized water, and place it on a magnetic stirrer to stir for 10 minutes to obtain a 0.2 mol / L aqueous solution of diamine hydrogen phosphate.

[0053] (4) According to the molar ratio of calcium element and phosphorus element being 5:3, mix the calcium ion solution in step (2) wit...

Embodiment 2

[0056] The preparation method of the hydroxyapatite of the present embodiment is as follows:

[0057] (1) Soak discarded clam shells in an aqueous solution of 5% sodium hypochlorite for 1 hour, then wash them with deionized water for 3 times, and then air dry them naturally. The clam shell is crushed mechanically to obtain the clam shell powder.

[0058] (2) Pass the clam shell powder through a 200-mesh sieve, then weigh 1g of clam shell powder and dissolve it in 1L of 0.02mol / L hydrochloric acid aqueous solution, place it on a magnetic stirrer and stir for 10 minutes to obtain 0.01mol / L L calcium ion solution.

[0059] (3) Weigh 0.71 g of sodium hydrogen phosphate, dissolve it in 500 mL of deionized water, and place it on a magnetic stirrer to stir for 10 minutes to obtain a 0.01 mol / L aqueous solution of sodium hydrogen phosphate.

[0060] (4) According to the molar ratio of calcium element and phosphorus element of 5:3, mix the calcium ion solution in step (2) with the aq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com