Viscose-based nitrogen-containing active carbon fiber material as well as preparation method and application thereof

A technology of activated carbon fiber and viscose fiber, which is applied in the field of viscose-based nitrogen-containing activated carbon fiber materials and its preparation, can solve the problems that the adsorption performance cannot meet the use requirements, and achieve effective reuse, obvious economic benefits, and reduce energy consumption cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

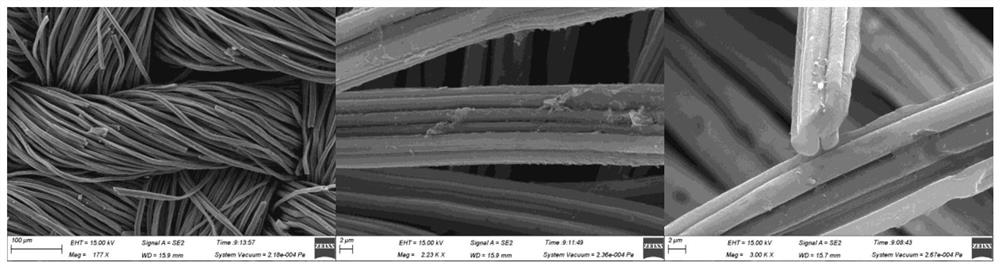

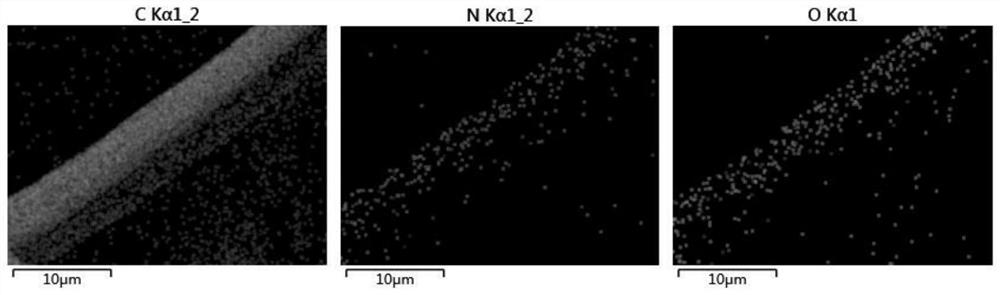

[0064] Concrete, the preparation method of viscose base nitrogen-containing activated carbon fiber of the present invention, comprises the following steps:

[0065] (1) Pretreatment

[0066] First, the waste viscose fabric is ultrasonically cleaned in ethanol and deionized water in sequence to remove dust and impurities on the fiber surface, and then dried;

[0067] Then, with NH 4 Cl and ZnCl 2 The mixed salt solution soaks the dried viscose fiber fabric for 60min, using the mixed salt solution can increase the output after calcination and reduce the ash content; then dry it; wherein, NH 4 Cl and ZnCl 2 The concentration of the mixed salt solution is: 5wt% NH 4 Cl and 5wt% ZnCl 2 , dried in a drying oven at 60°C for 240 minutes after soaking;

[0068] (2) Activation-carbonization treatment

[0069] The viscose fiber fabric of step (1) gained is placed in porcelain boat, then porcelain boat is placed in tube furnace, in N 2 The heating treatment was carried out under t...

Embodiment 1

[0084] The preparation method of the viscose-based nitrogen-containing activated carbon fiber material of the present embodiment comprises the following steps:

[0085] (1) Pretreatment

[0086] Put the 5cm×5cm waste viscose fiber fabric into ethanol and deionized water for ultrasonic cleaning to remove dust and impurities on the surface of the fiber, and dry it in an oven at 60°C for 240min after cleaning;

[0087] Weigh 2.78g of NH 4 Cl and 2.78g of ZnCl 2 , dissolved in 50 mL of deionized water to make 5 wt% NH 4 Cl and 5wt% ZnCl 2 mixed salt solution, then soak the cleaned waste viscose fabric for 60 minutes, dry it in an oven at 60°C for 240 minutes after soaking, and complete the pretreatment of waste viscose fabric;

[0088] (2) Activation-carbonization treatment

[0089] Put the treated viscose fiber fabric into a porcelain boat, place it in a tube furnace, and under the protection of nitrogen atmosphere (the flow rate of nitrogen gas is 40mL / min), raise the tempe...

Embodiment 2

[0101] The preparation method of the viscose-based nitrogen-containing activated carbon fiber material of this embodiment is only different from that of Example 1 in that the heating temperature in step (2) under a nitrogen atmosphere is 700°C, and after reaching 700°C, the nitrogen gas is converted into Carbon dioxide gas with a flow rate of 40mL / min was activated and carbonized at a constant temperature for 60min. Other preparation steps are the same as those in Example 1 and will not be repeated here.

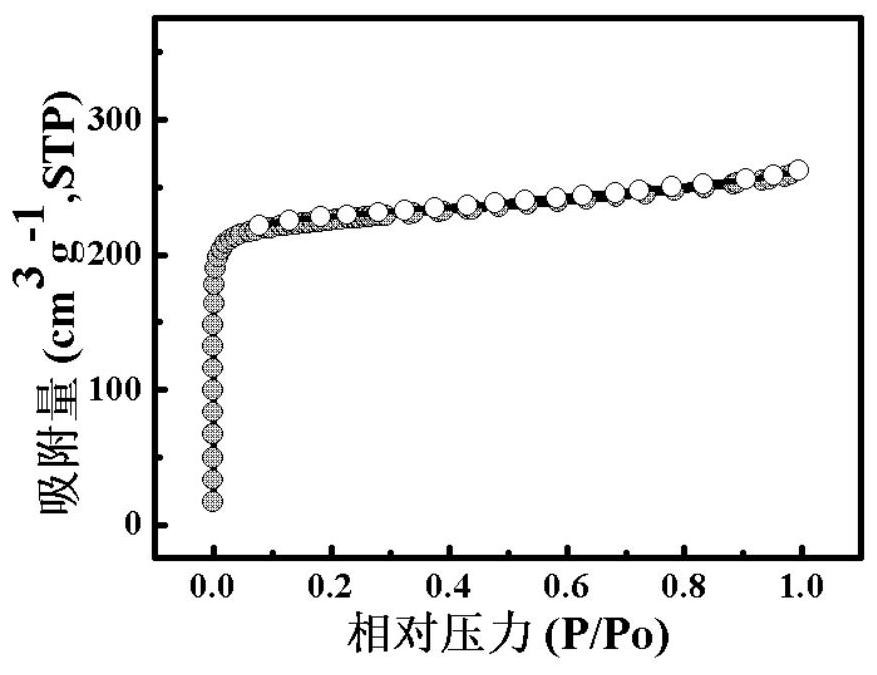

[0102] The nitrogen isothermal adsorption-desorption curve measured under the condition of -196 ℃ for the viscose-based nitrogen-containing activated carbon fiber material of the present embodiment is as follows: Figure 7 As shown, according to the classification of the International Union of Pure and Applied Chemistry, it can be known that the nitrogen isotherm adsorption-desorption curve conforms to Type I, indicating that the pores of the viscose-based nitrogen-containin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com