Patents

Literature

35results about How to "Reduce reagent consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

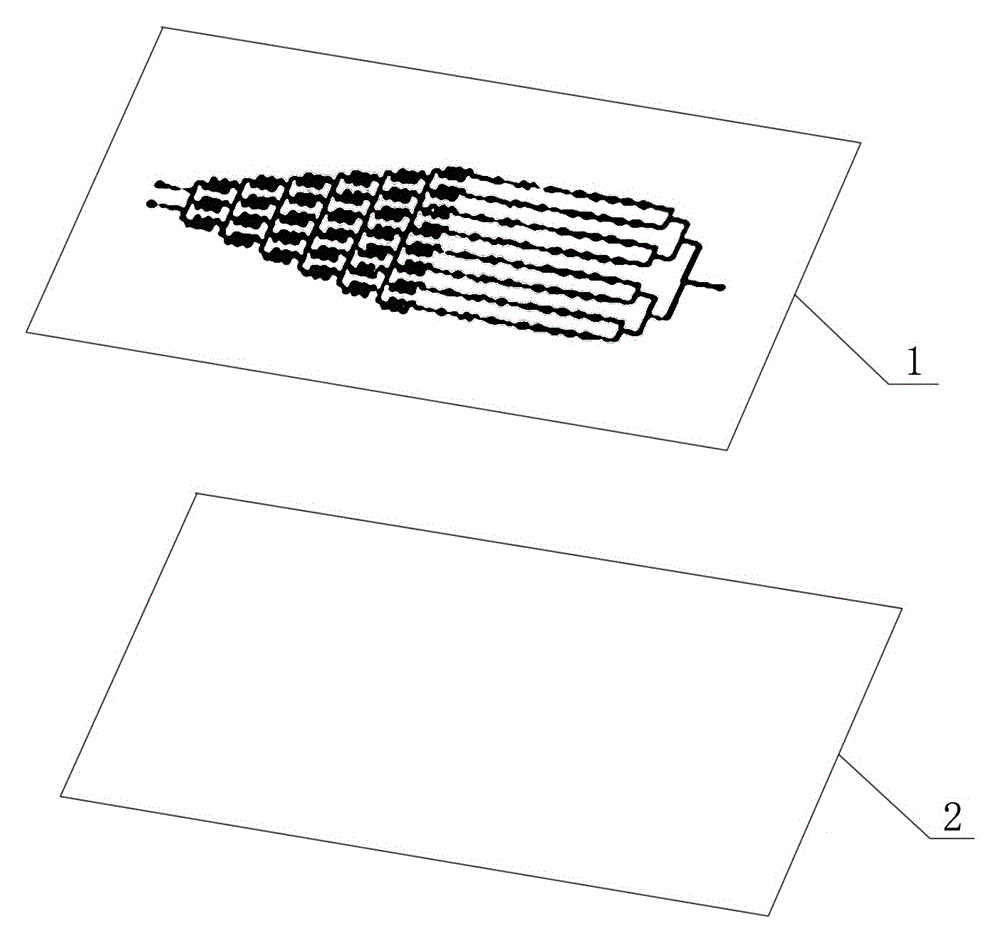

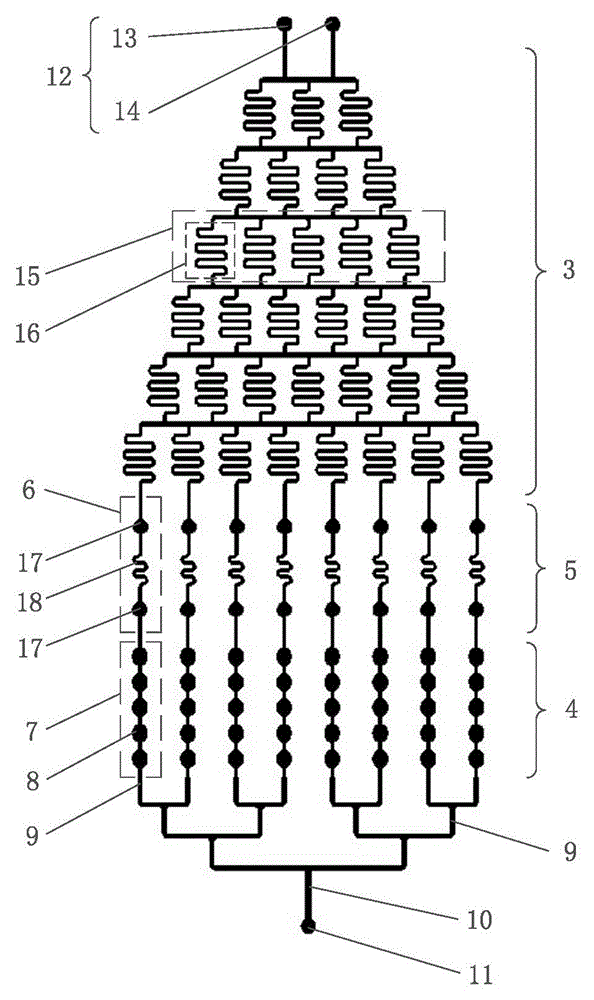

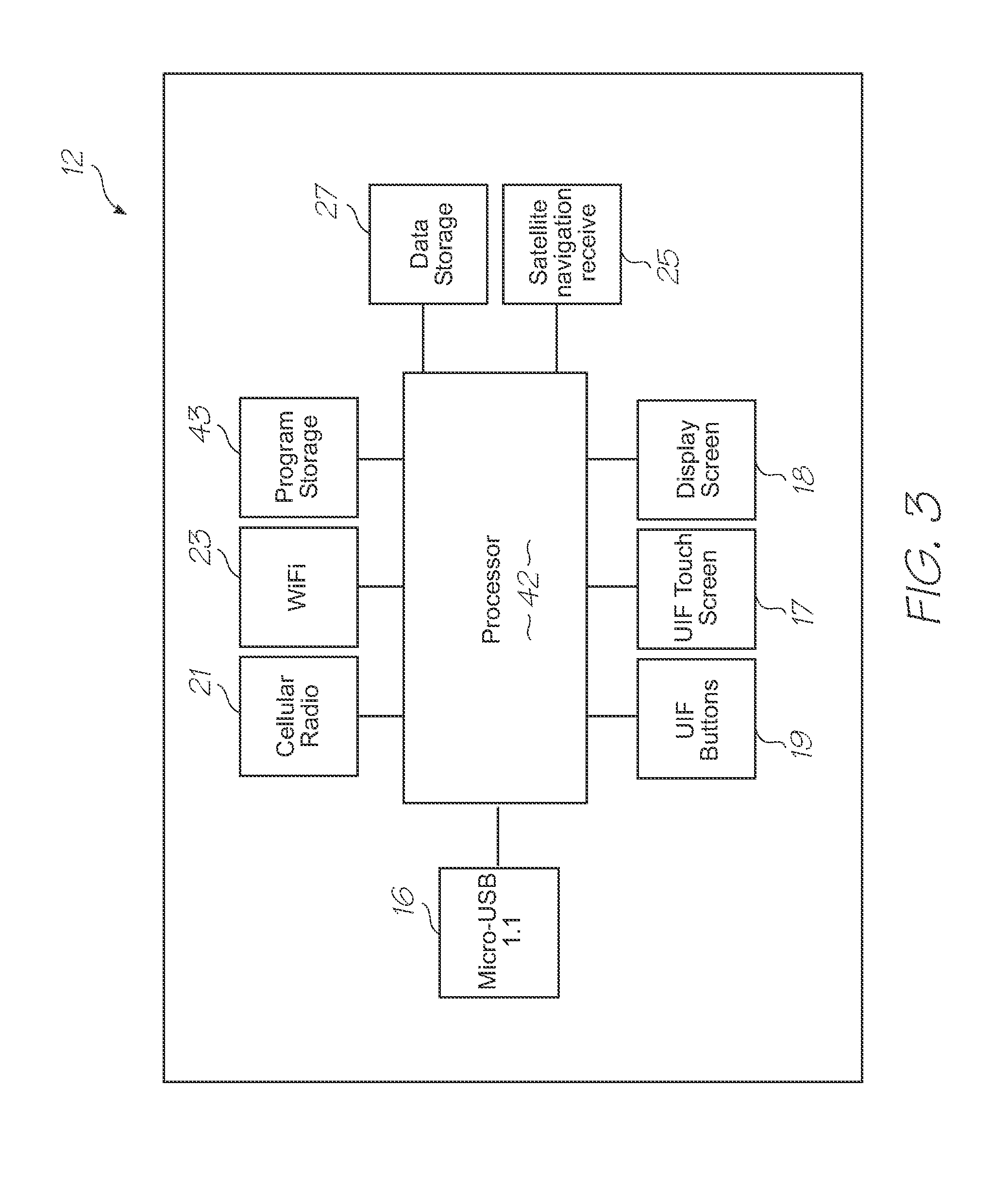

Integrated microfluidic chip for screening medicine and method for applying integrated microfluidic chip

InactiveCN105080627AReduce in quantityReduce reagent consumptionMicrobiological testing/measurementLaboratory glasswaresMicrofluidic chipOn cells

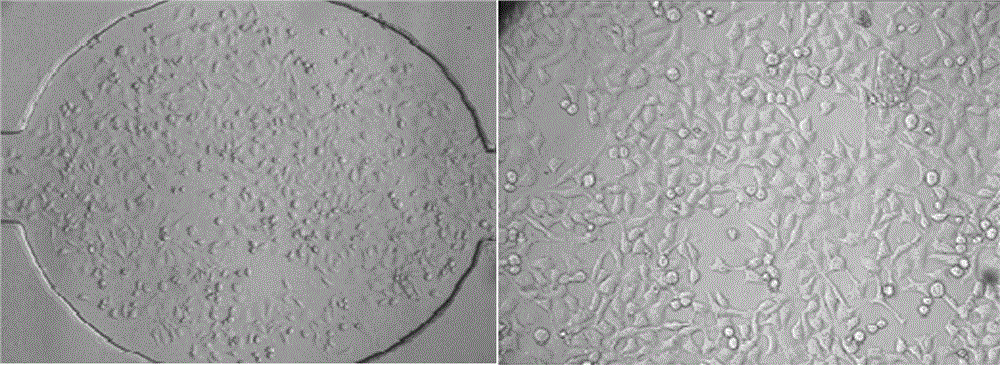

The invention discloses an integrated microfluidic chip for screening medicine. The integrated microfluidic chip comprises a PDMS (polydimethylsiloxane) fluid channel layer and a glass layer. The PDMS fluid channel layer and the glass layer are bonded with each other by oxygen plasma to form a fluid channel unit which is of an irreversible structure; the fluid channel unit comprises a concentration gradient generation structural region, an array cell culture region and a buffer structural region. The invention further provides a method for applying the integrated microfluidic chip. The integrated microfluidic chip and the method have the advantages that medicine concentration gradient generation, chip cell culture, medicine stimulation on cells, result generation and detection are integrated on the chip, the buffer structural region can be opened and closed, accordingly, the concentration gradient generation structural region and the array cell culture region can independently work and integrally run, and various functions can be flexibly switched over; cell inoculation, stimulated, washing and dyeing operation procedures and the like can be simplified by the aid of the method, various experimental correlation parameters can be obtained by means of one-step running, and a novel technical platform and the novel method can be provided for medicine screening and cell-medicine research.

Owner:LIAONING UNIV OF TRADITIONAL CHINESE MEDICINE

Method for producing vanadium oxide

InactiveCN103194611AReduce reagent consumptionReduce manufacturing costVanadium oxidesProcess efficiency improvementAmmonium carbonateHigh phosphorus

The invention provides a method for producing a vanadium oxide. The method comprises the following steps of: mixing vanadium slag with calcium oxide or limestone to form a mixed material; roasting the mixed material to obtain a calcified clinker; leaching the calcified clinker through 5 to 12wt% of sodium carbonate solution at 80 to 95 DEG C; separating the solid and the liquid after the leaching reaction, so as to obtain vanadium-containing liquid and residues; processing the vanadium-containing liquid in a desilicating manner, so that the silicon concentration in the vanadium-containing liquid is less than 0.1g / L; cooling the vanadium-containing leaching liquid to 10 to 20 DEG C; adding ammonium carbonate to the vanadium-containing leaching liquid; adjusting the molar ratio of NH4<+> / TV to 2.5 to 7 to precipitate ammonium metavanadate; filtering to obtain ammonium metavanadate and vanadium-precipitated wastewater; and processing ammonium metavanadate by oxidizing, roasting and deaminizing to prepare vanadium pentoxide or by reducing to prepare vanadium trioxide. By adopting the method for producing the vanadium oxide, the vanadium oxide can be prepared through general vanadium slag and high-calcium high-phosphorus vanadium slag in the premise that the environmental protection requirement is met, the agent consumption can be decreased, and the production cost is reduced.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

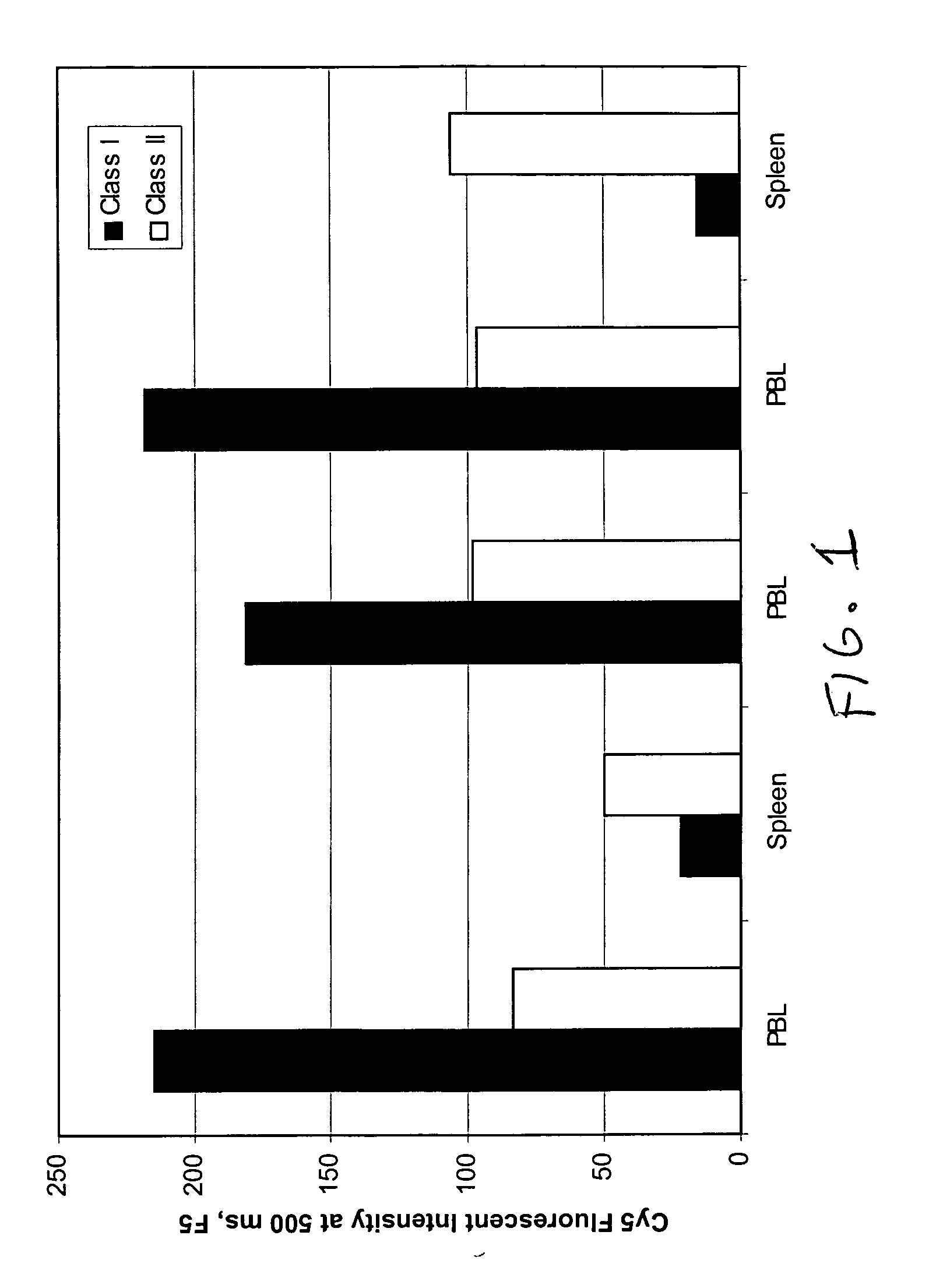

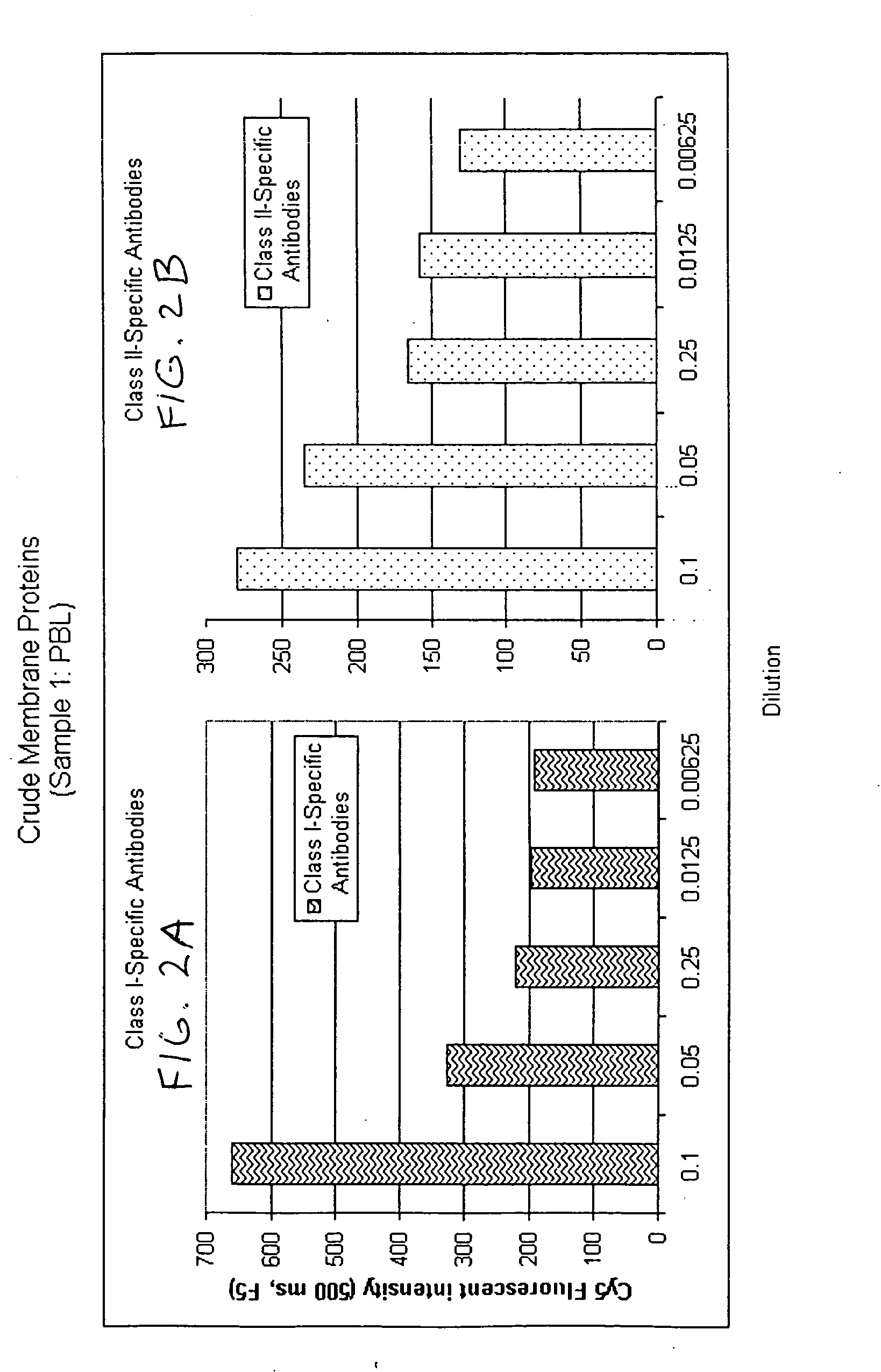

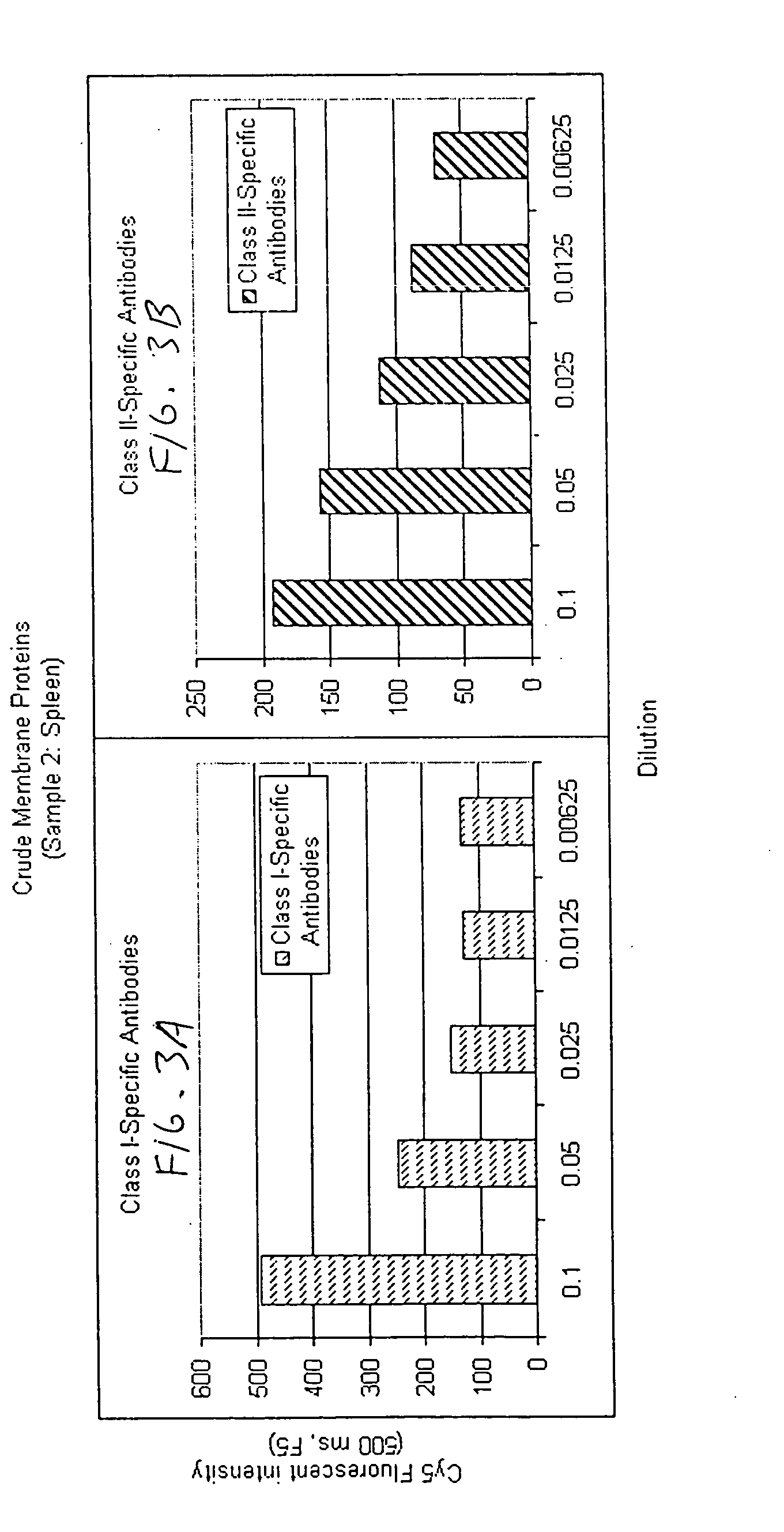

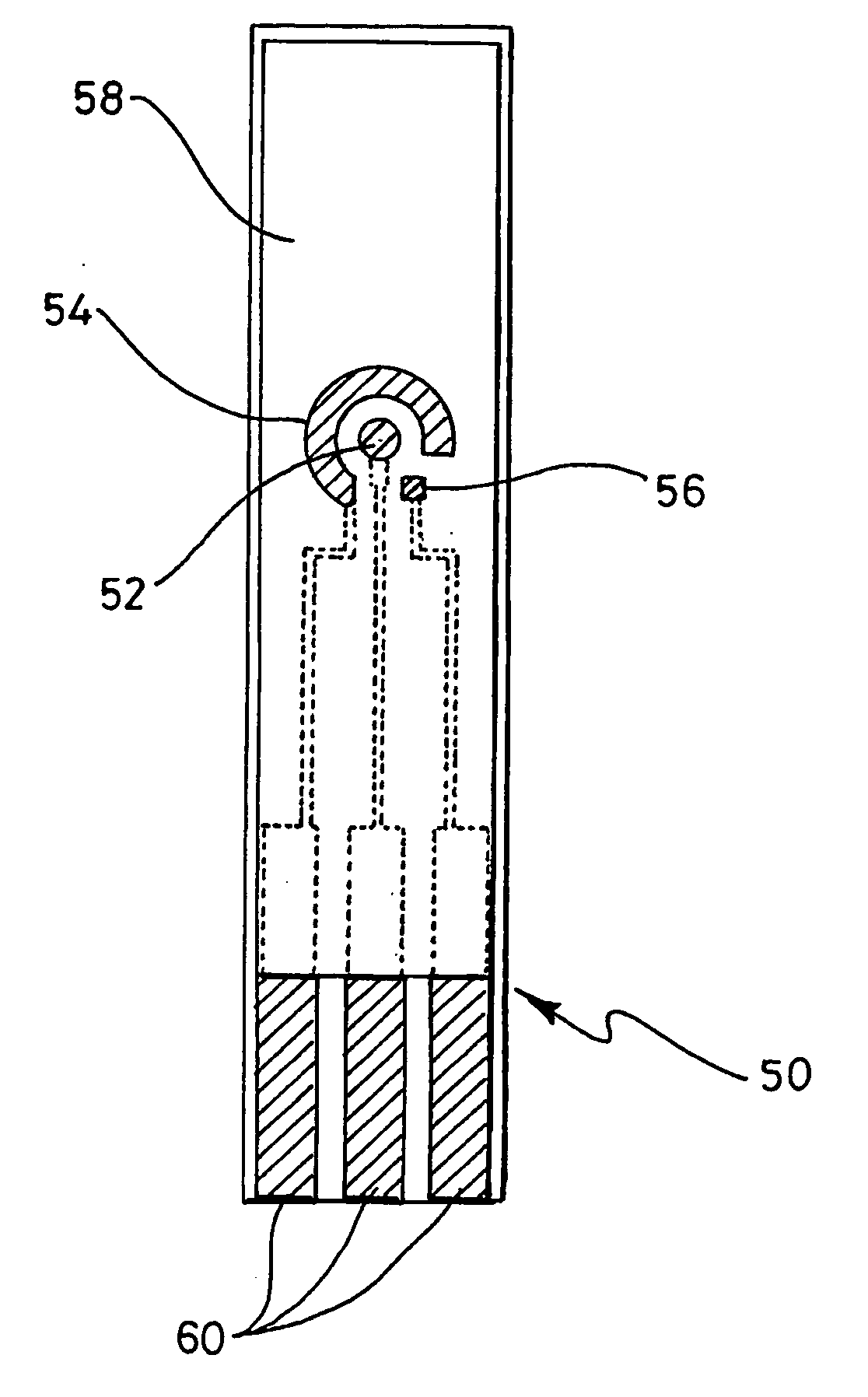

Detection of cell membrane-associated proteins using membrane fragments displayed on encoded microparticle arrays

InactiveUS20050059095A1Improve accuracySmall sizeBioreactor/fermenter combinationsBiological substance pretreatmentsAntigenCell membrane

Disclosed are methods relating to cell membrane fragments associated with microbeads, so that the characteristics of the cells the fragments originated from can be determined. The fragments can be oriented with what was the outer surface of the cell membrane facing outwardly, so that the antigens associated with the membrane can be contacted with ligands (including antibodies) to antigens in the membranes which would be accessible to antibodies in vivo. The system is useful, inter alia, for detection of panel reactive antibodies in donor serum, as well as detection of other cell membrane antigens; or quantitation of particular cell membrane antigens.

Owner:BIOARRAY SOLUTIONS

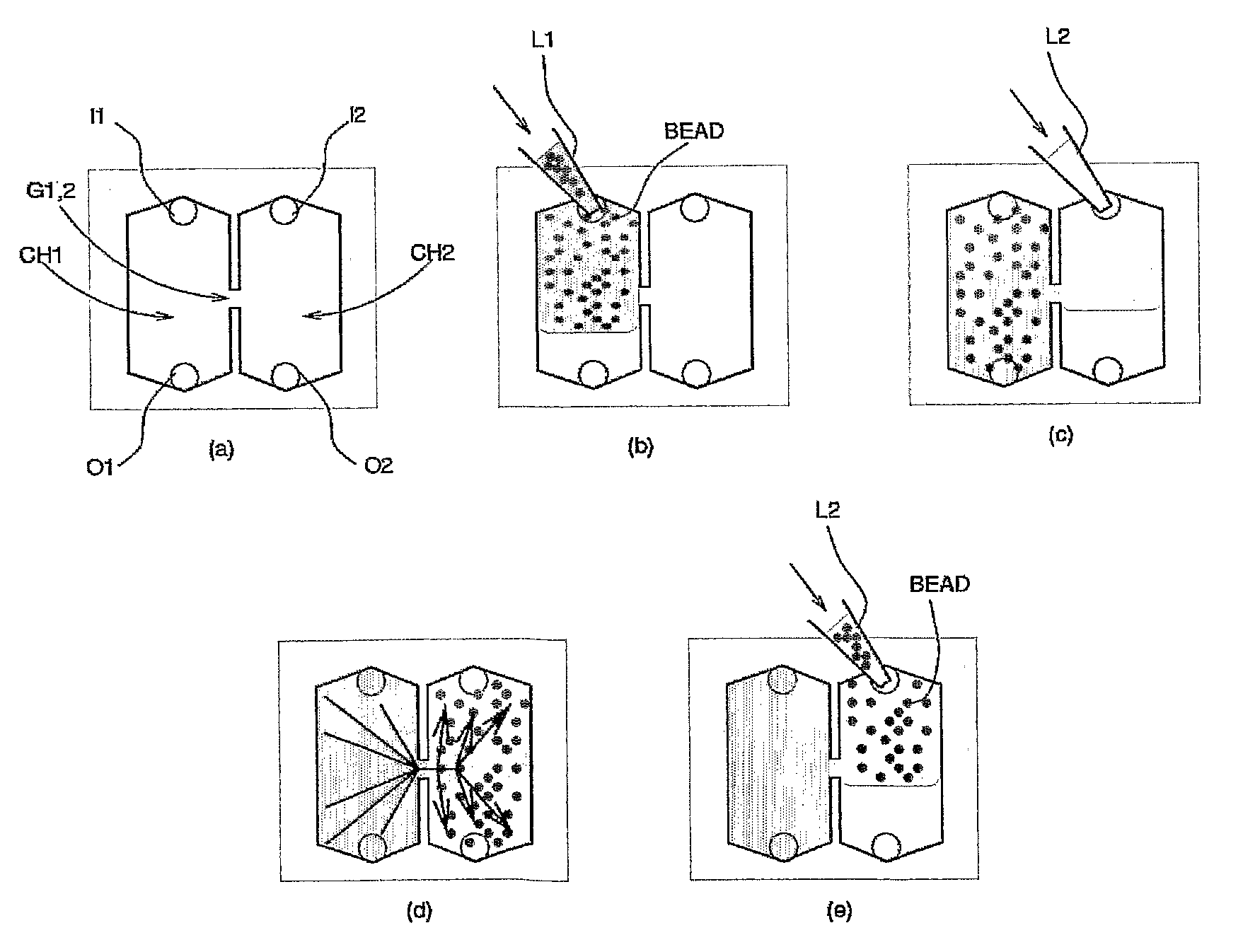

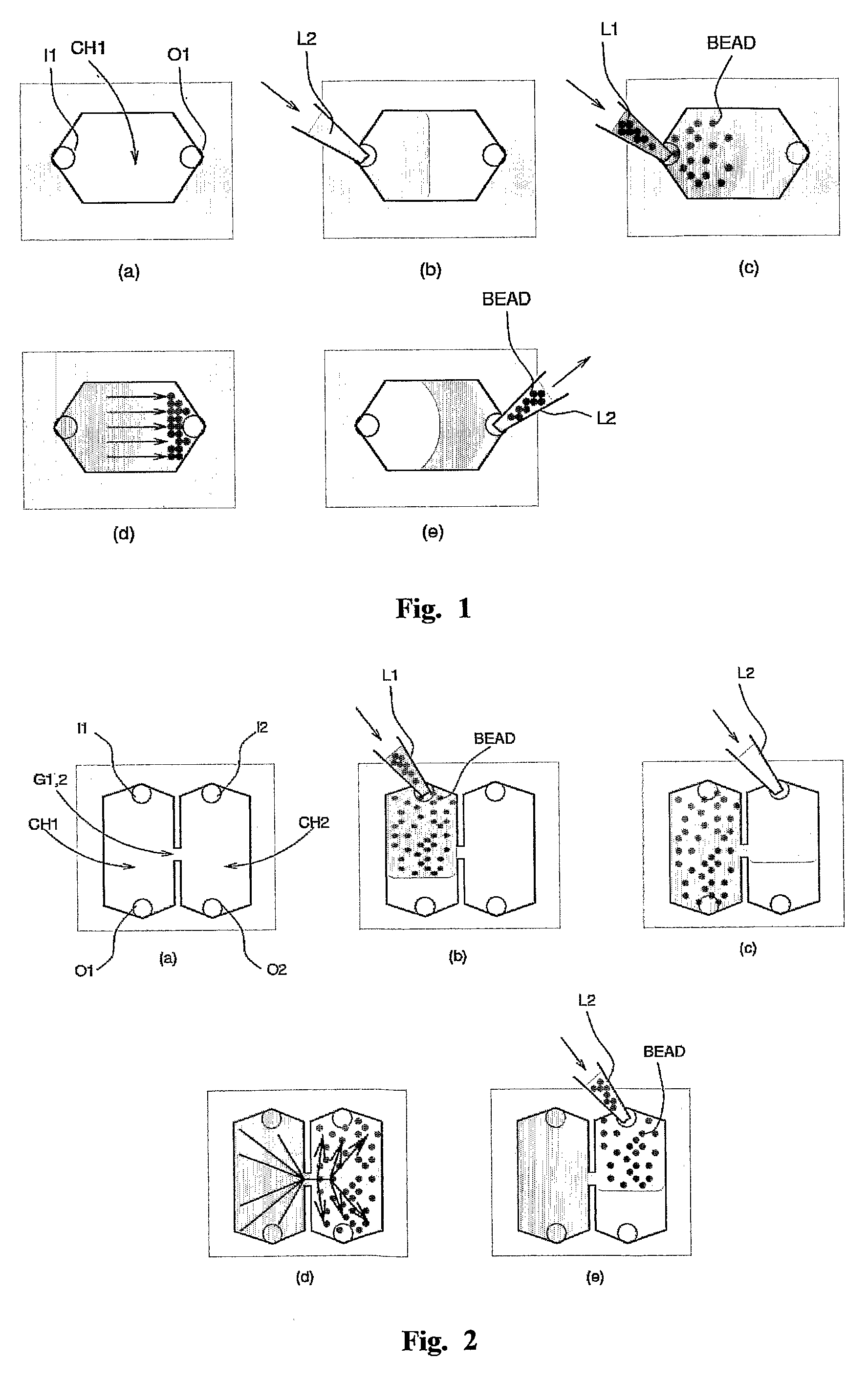

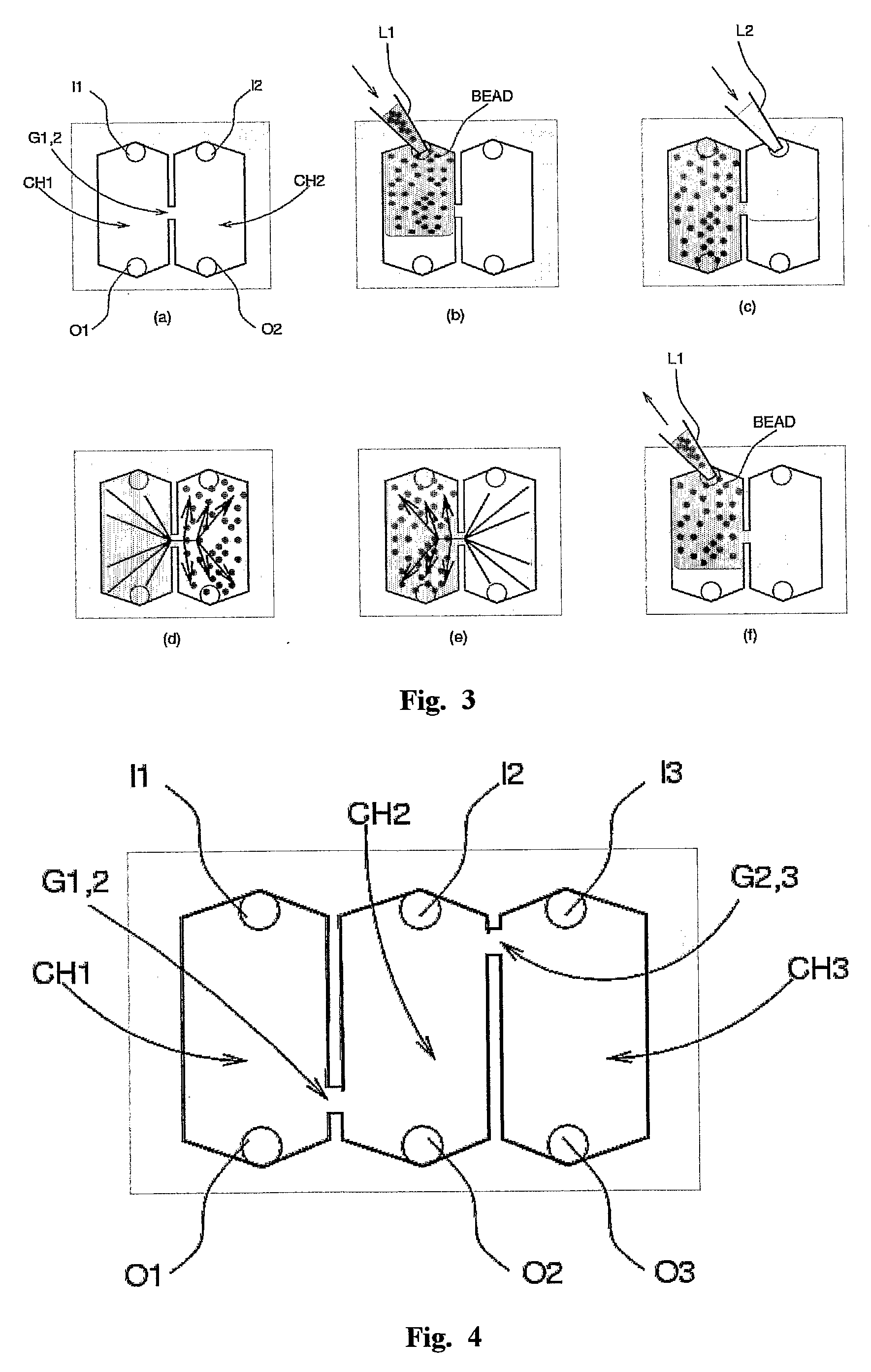

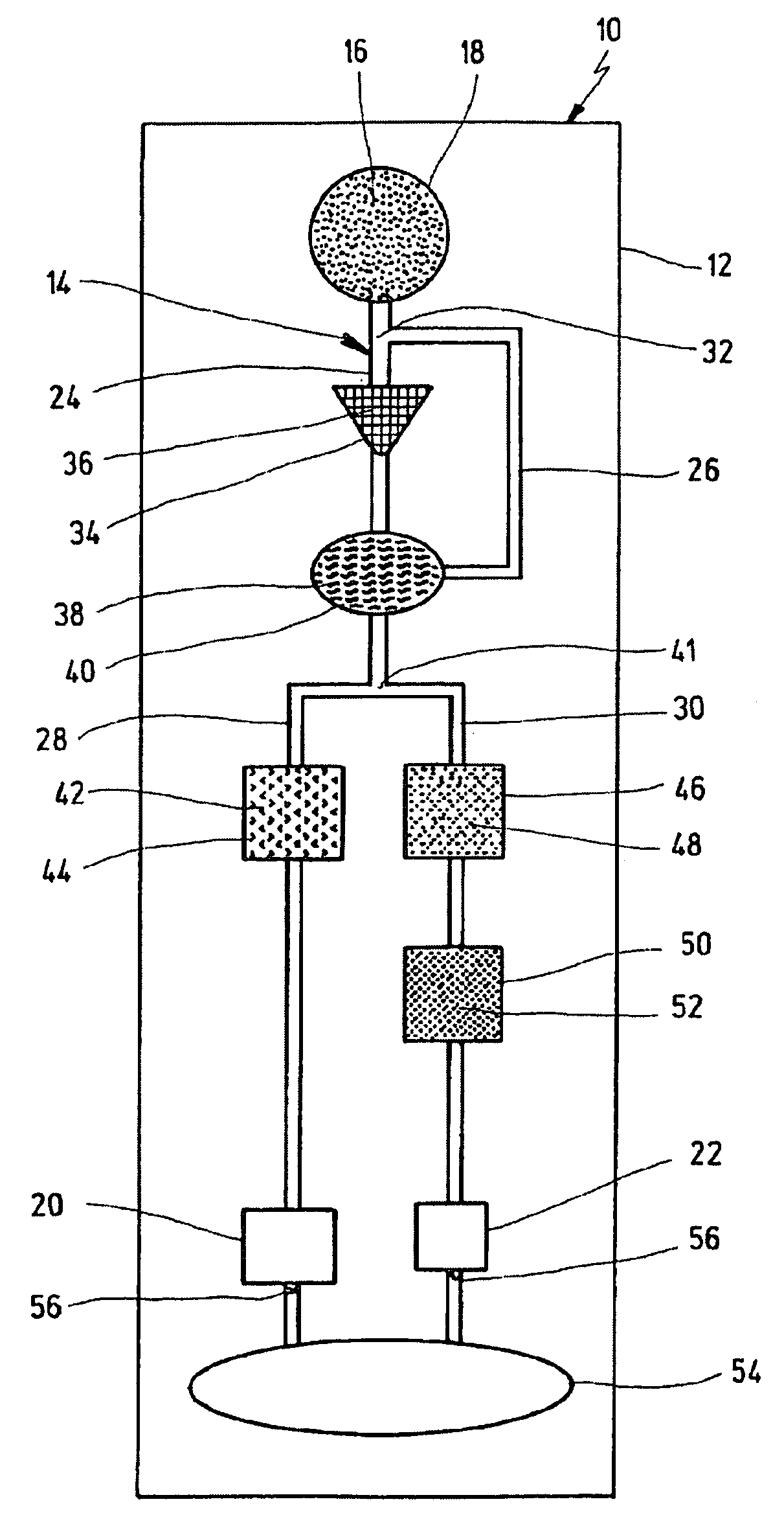

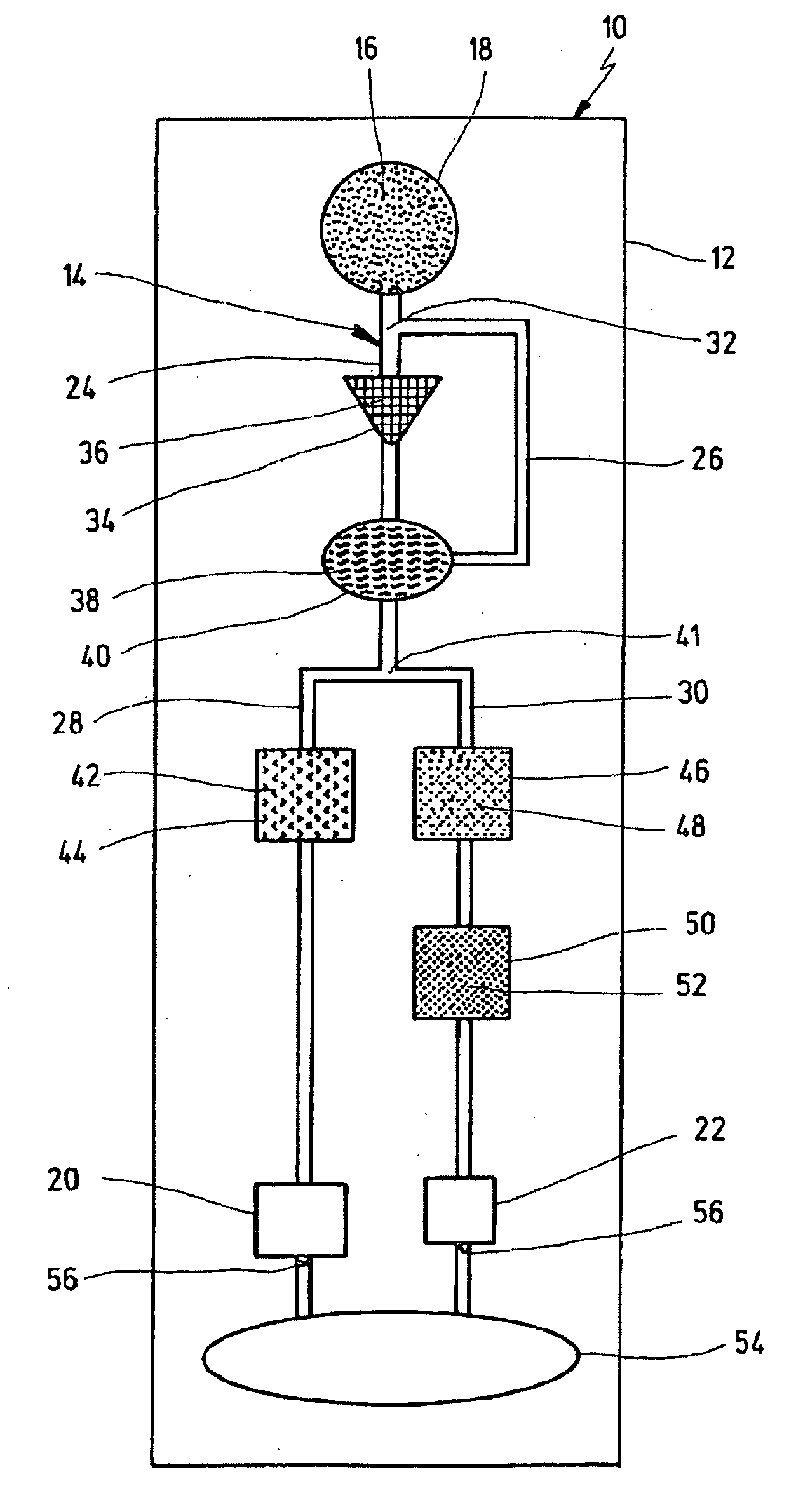

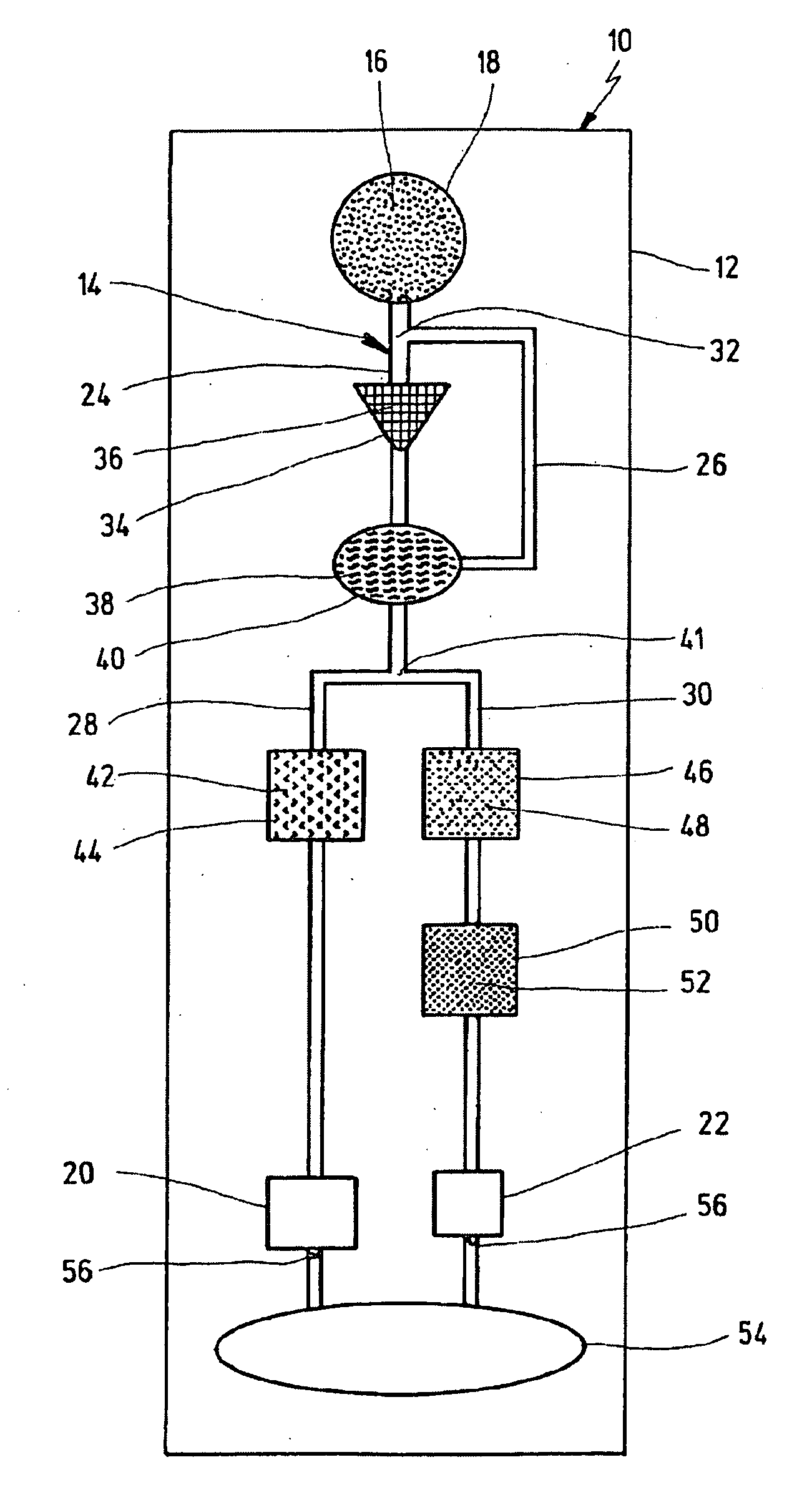

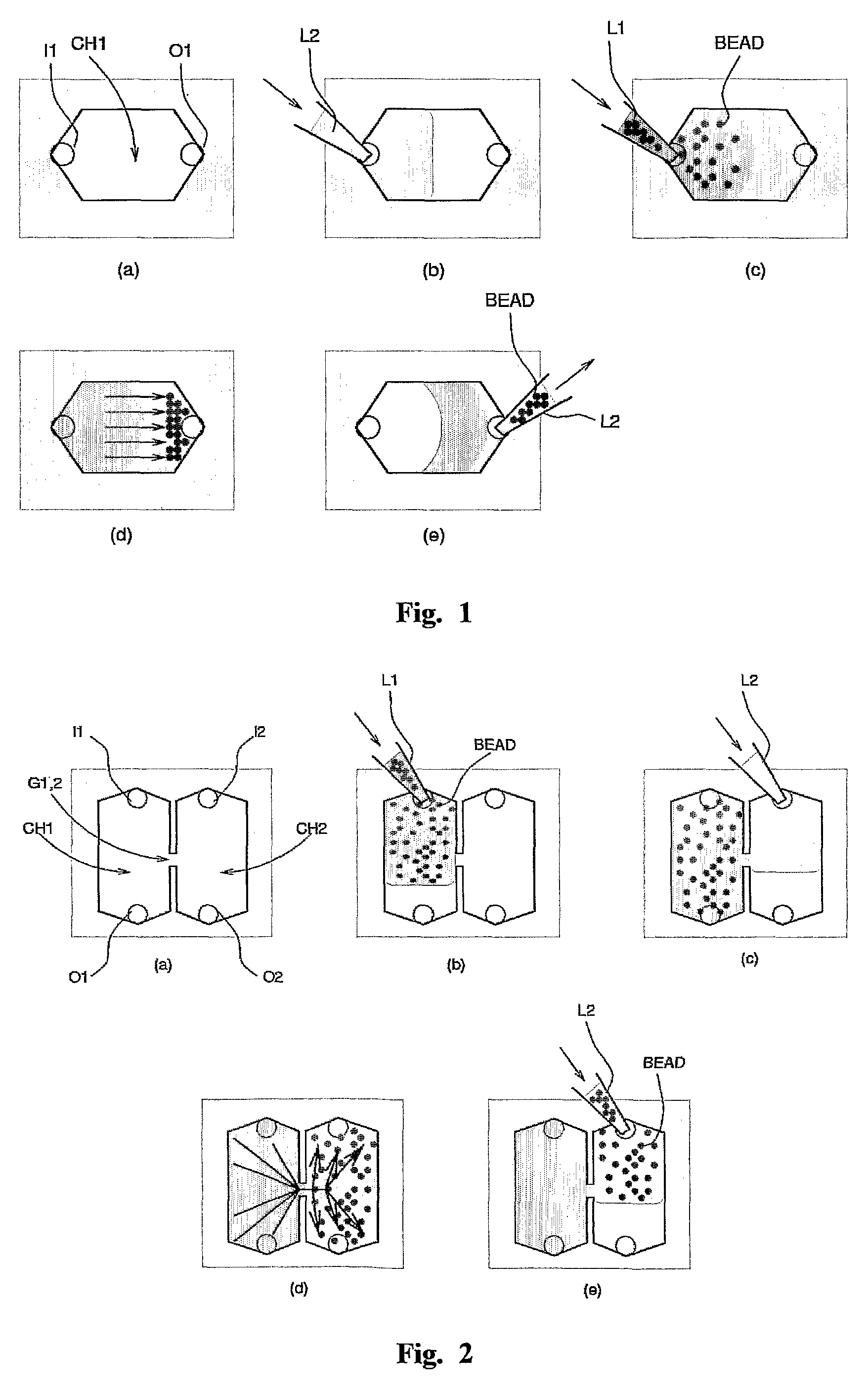

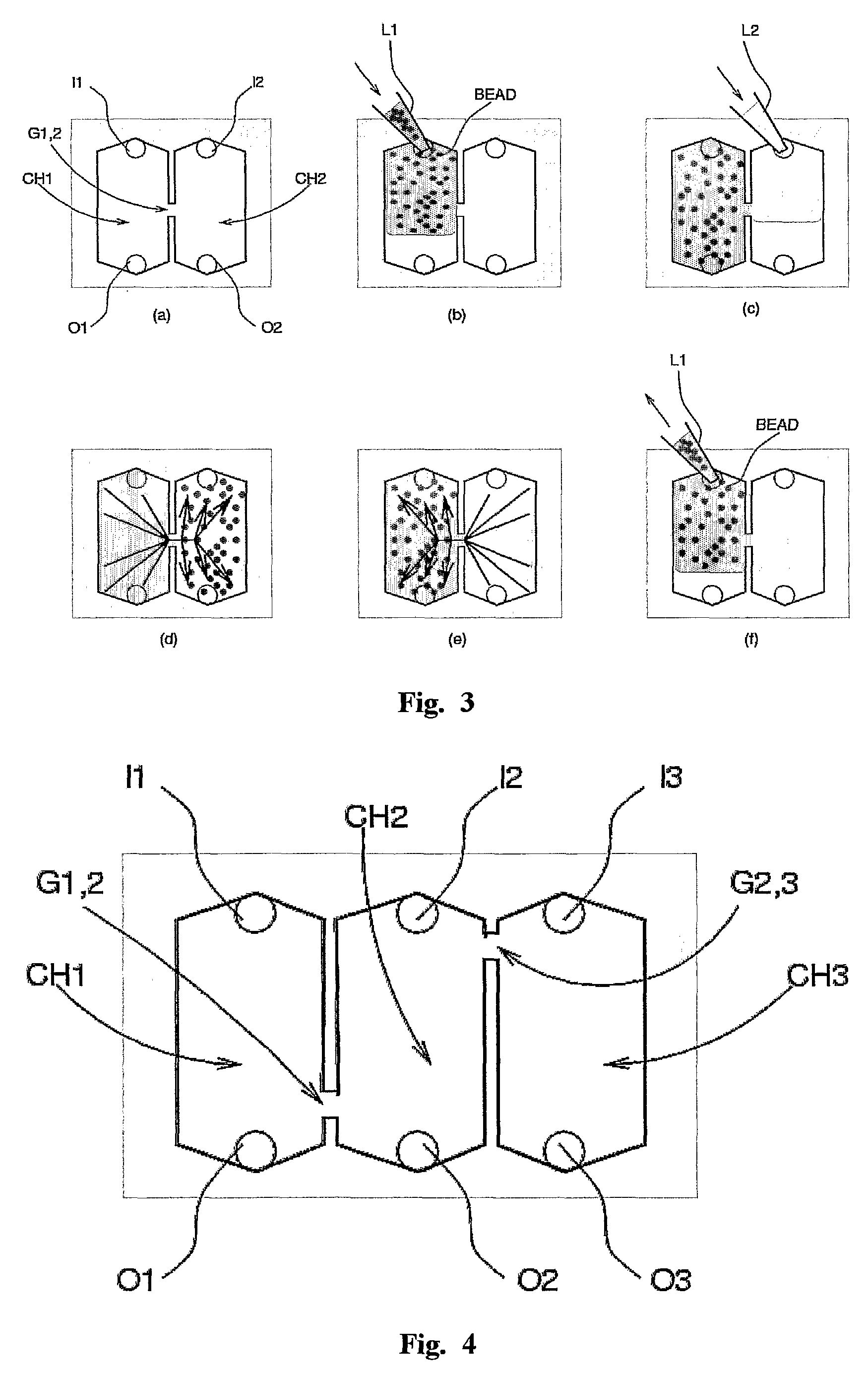

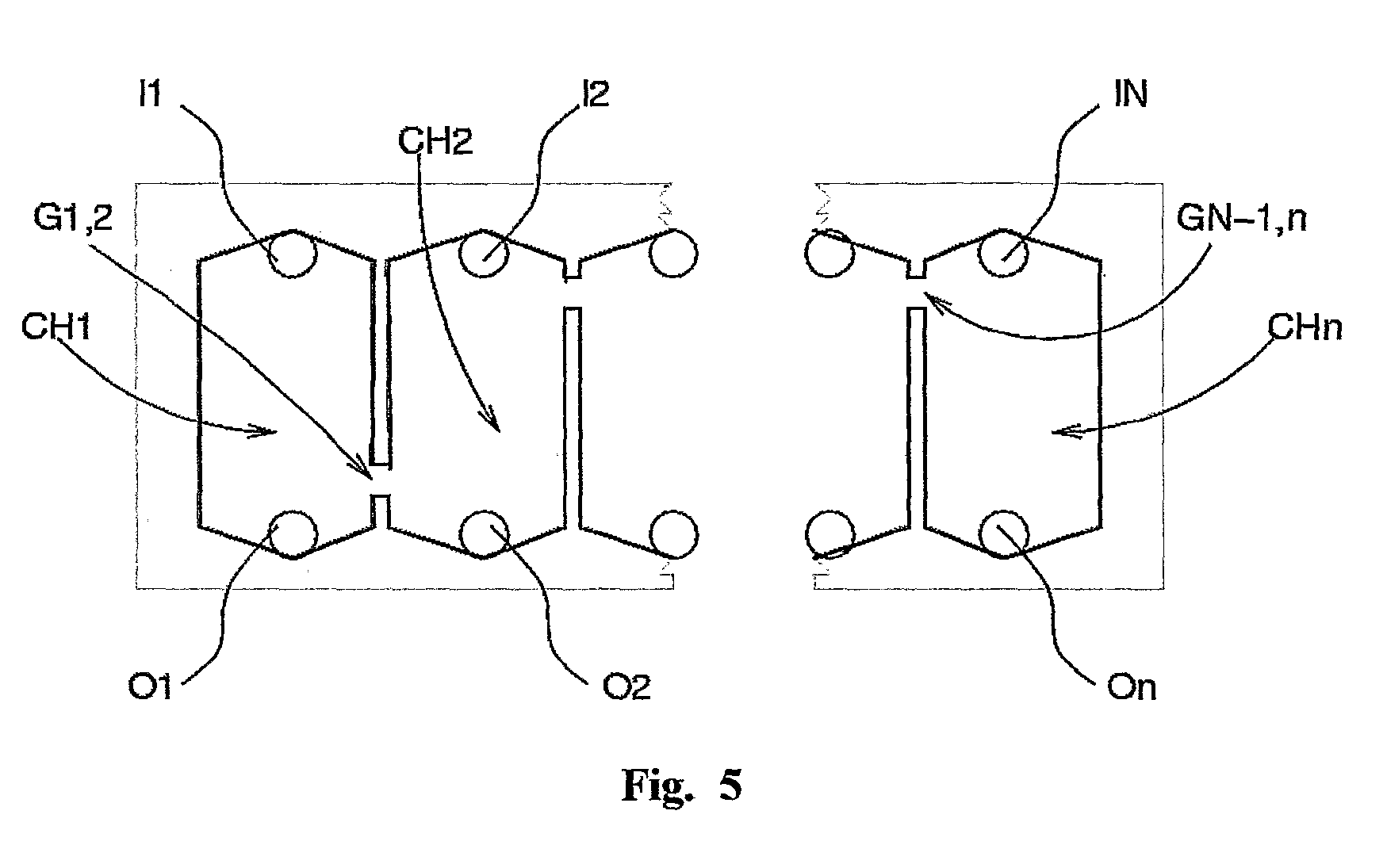

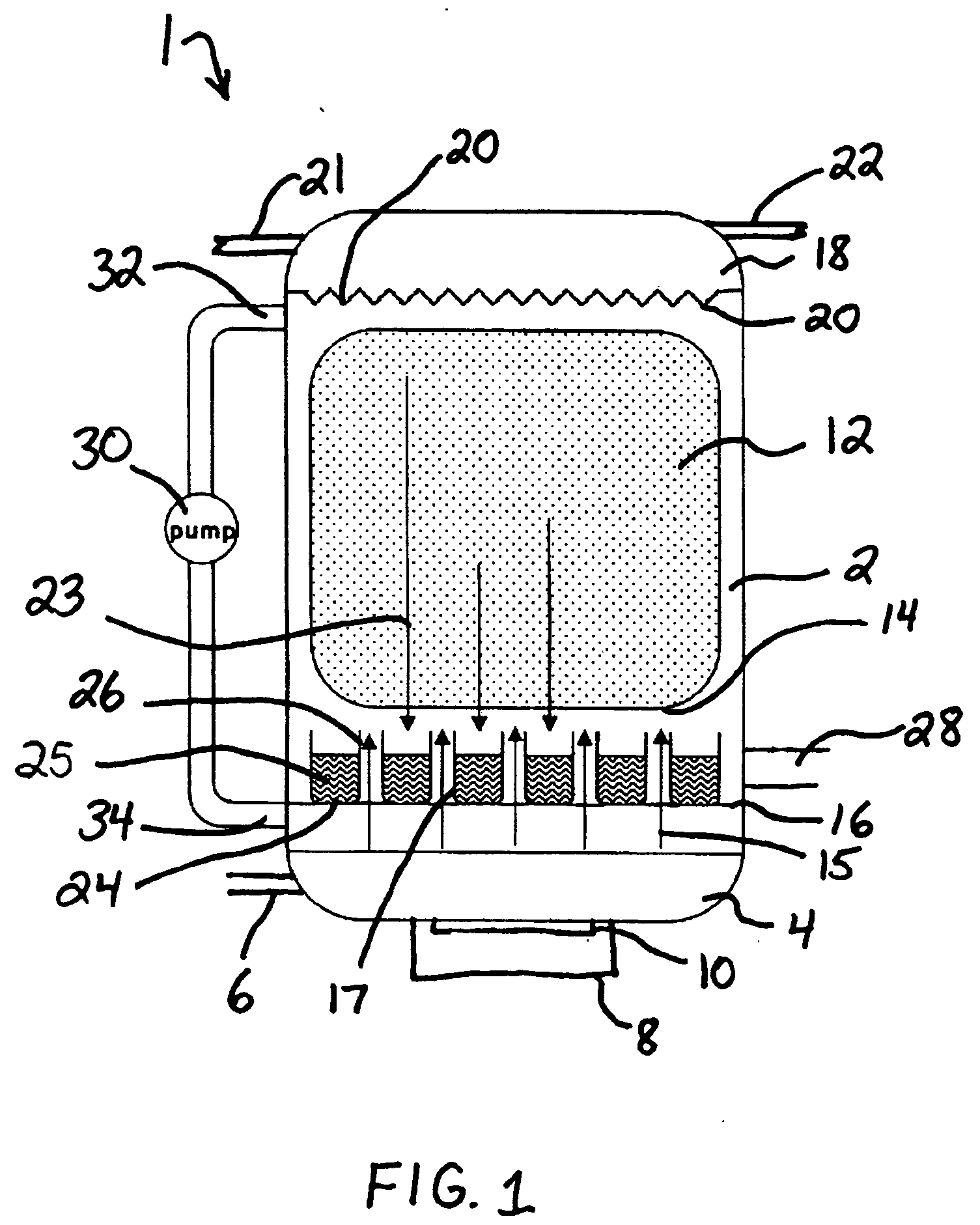

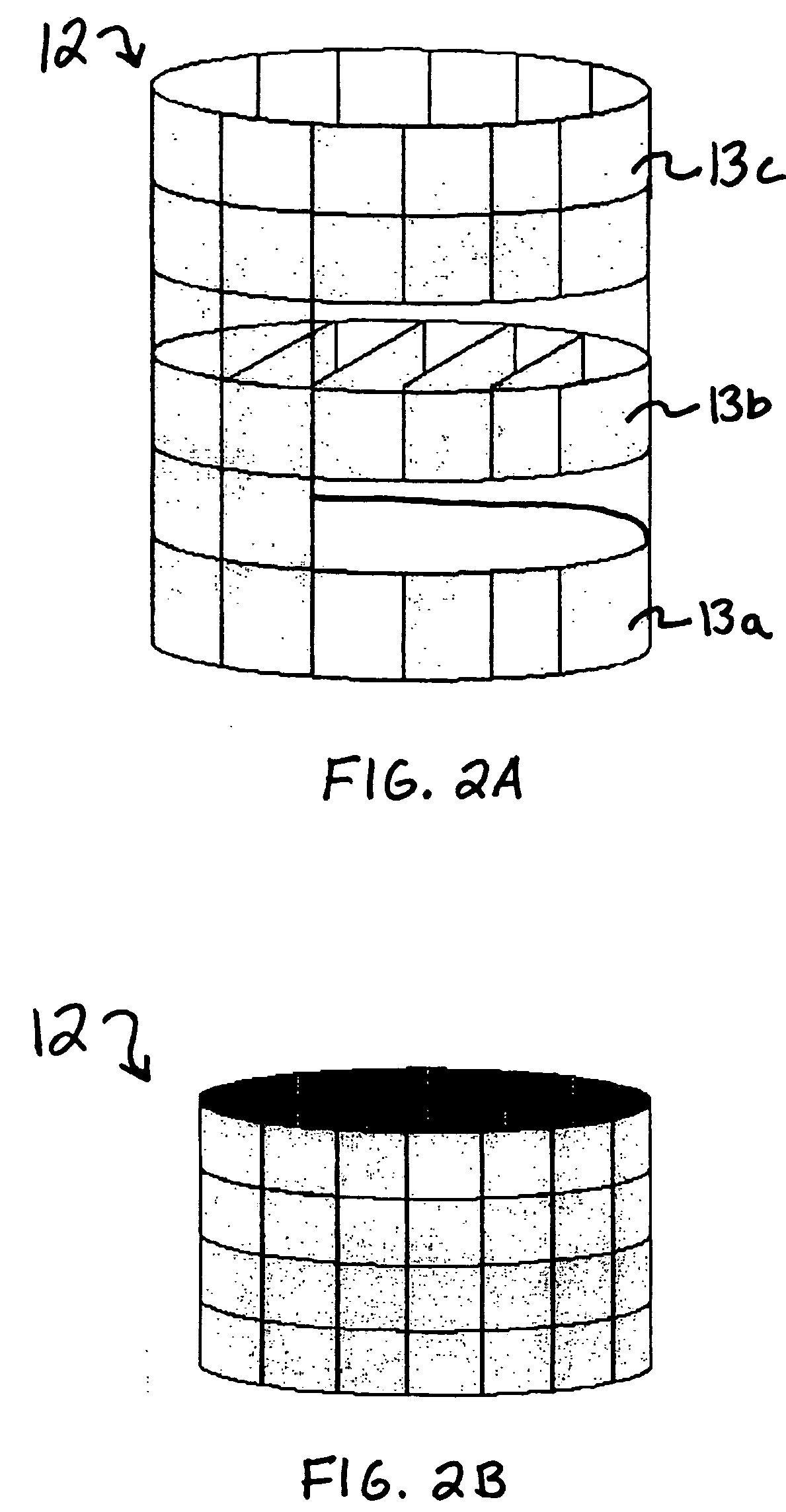

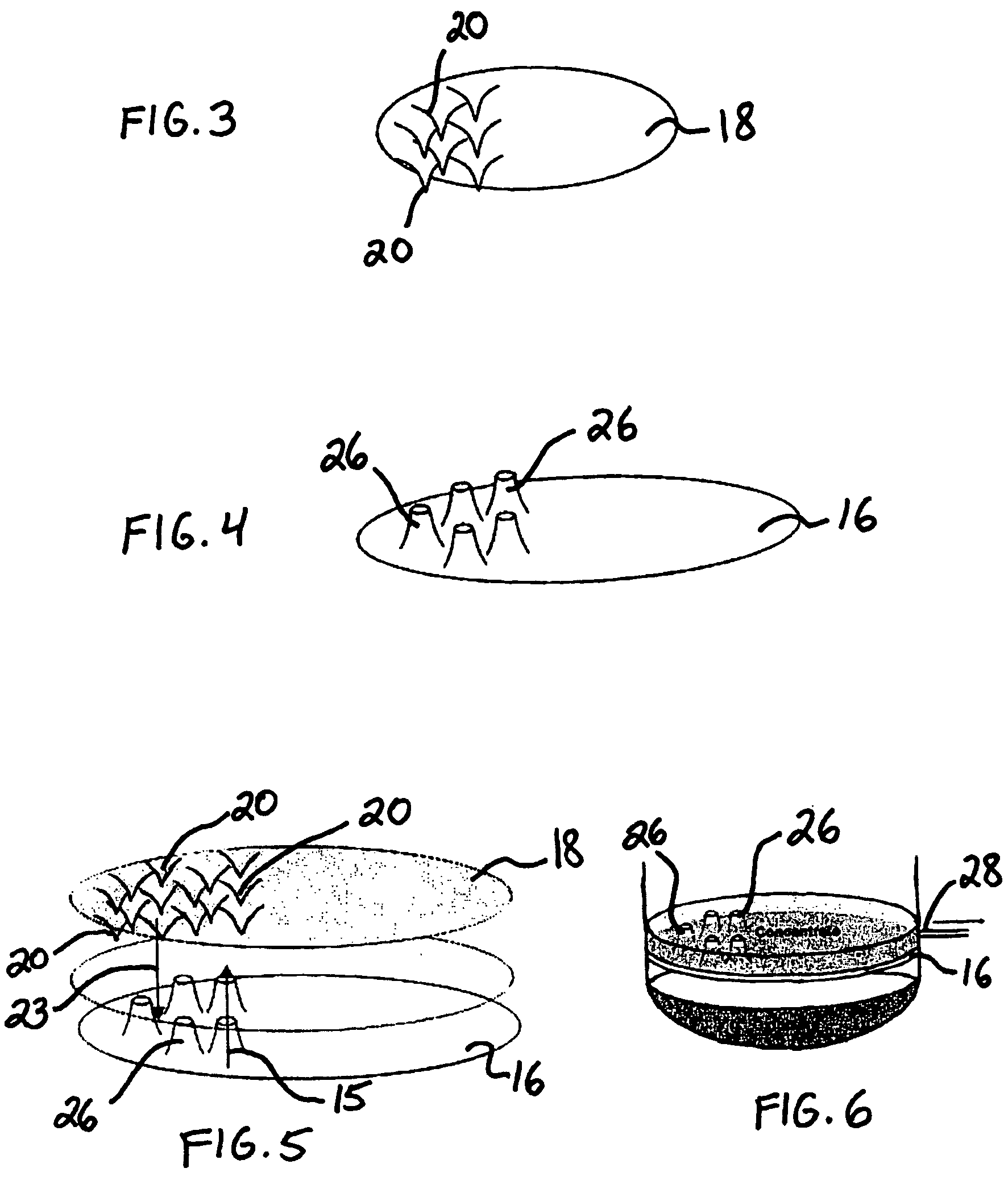

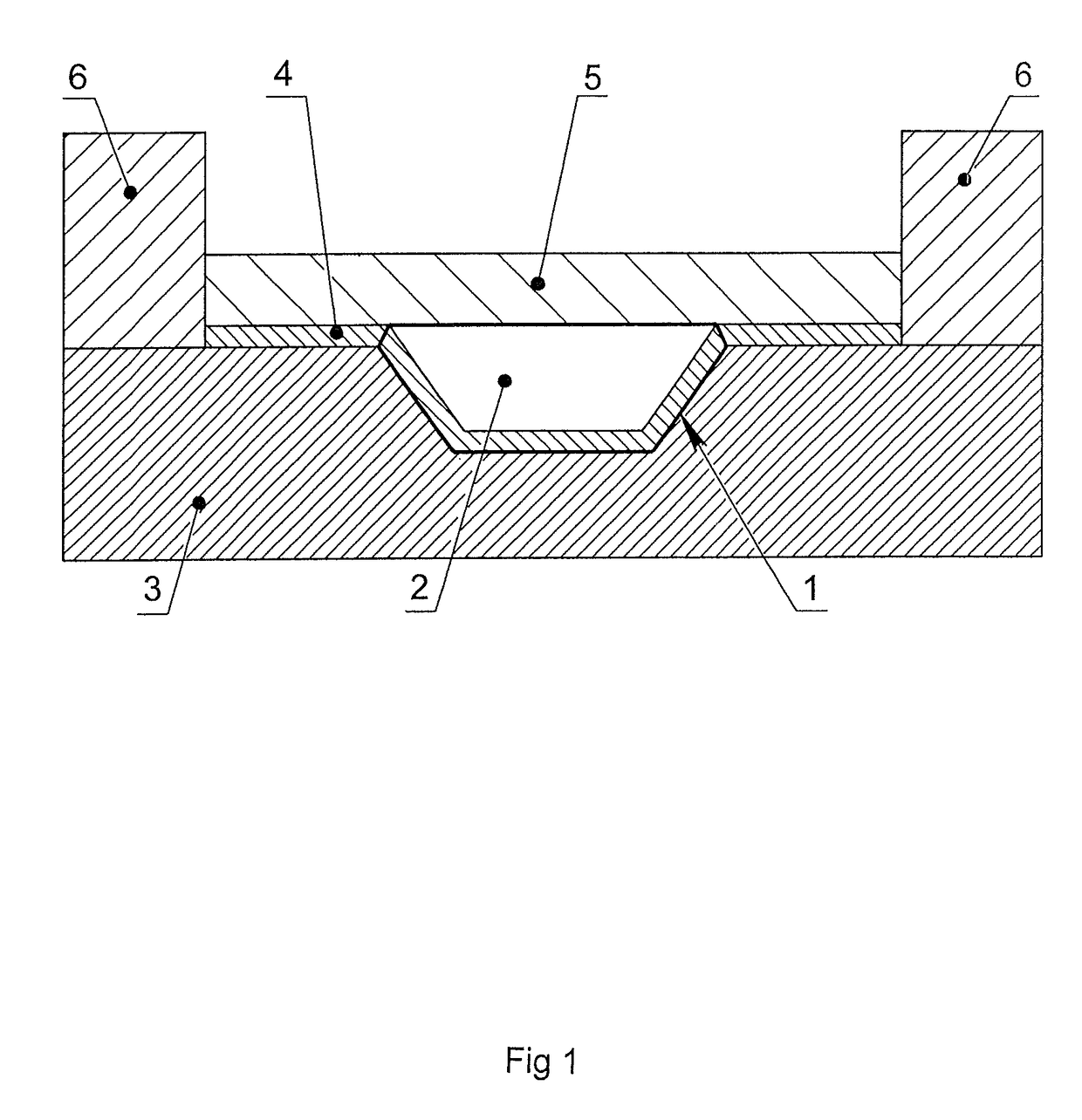

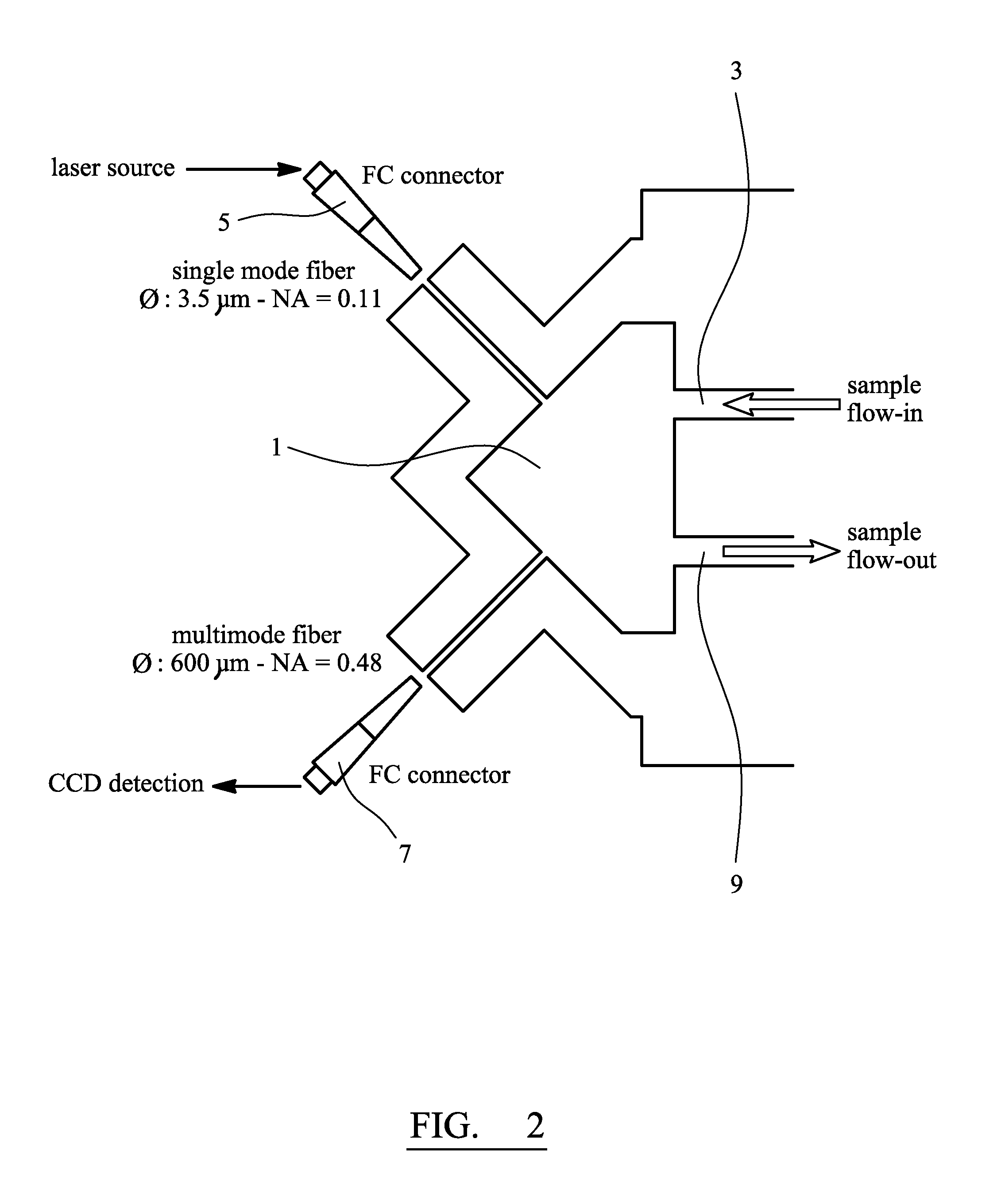

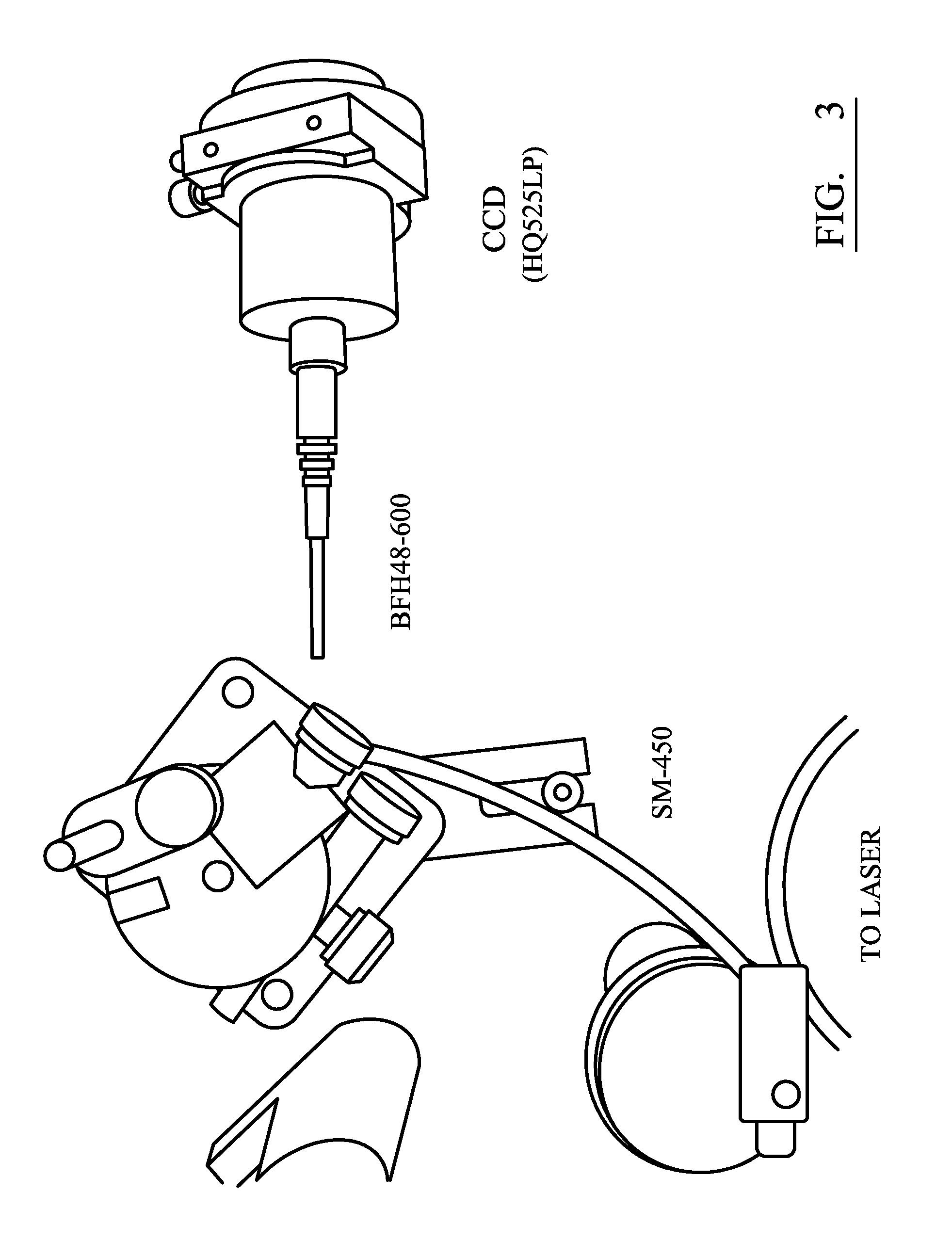

Method And Apparatus For The Processing And/Or Analysis And/Or Selection Of Particles, In Particular Biological Particles

ActiveUS20100248285A1Low reagent consumptionGreat delicacy of actionBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringBiological particles

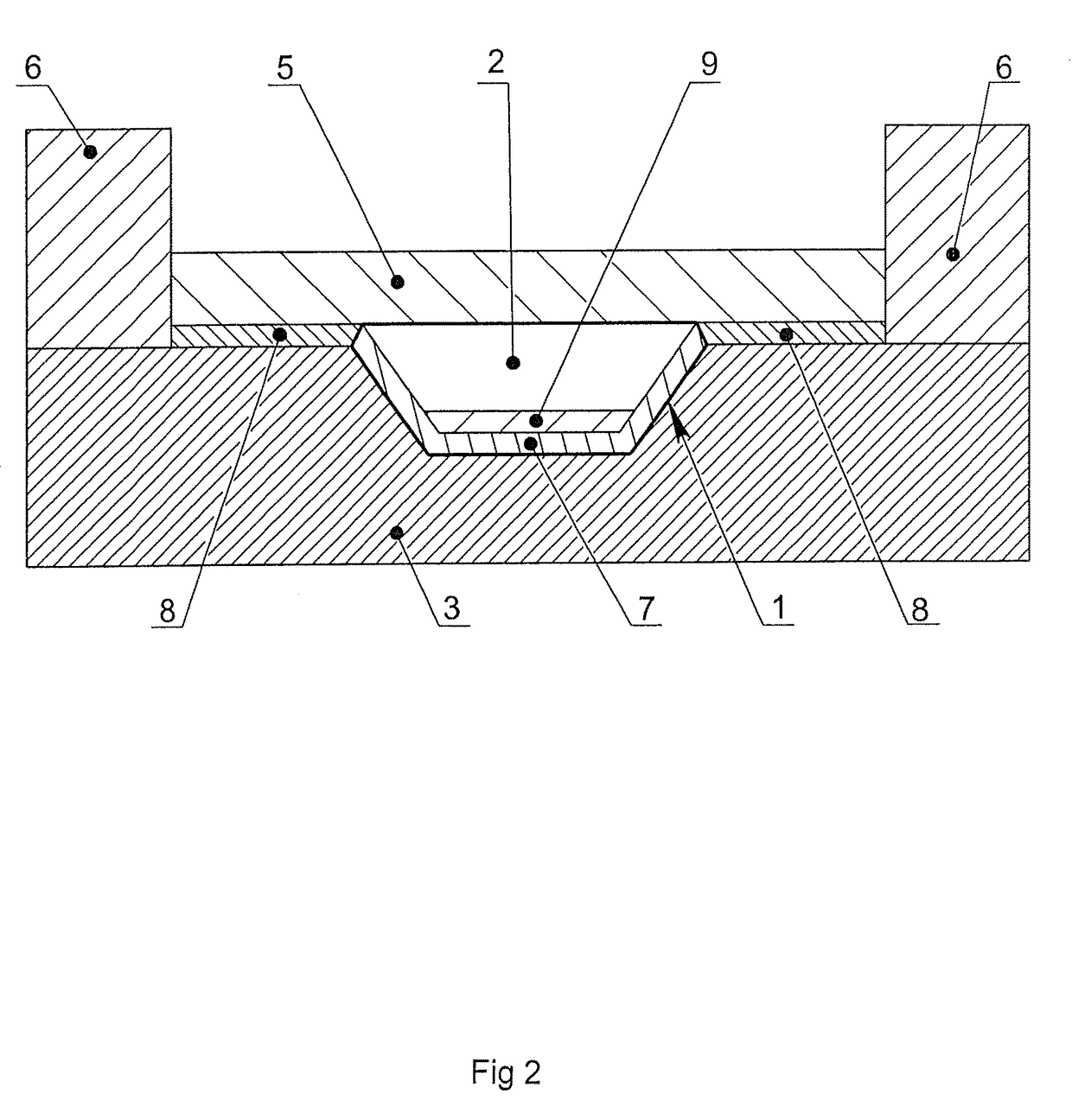

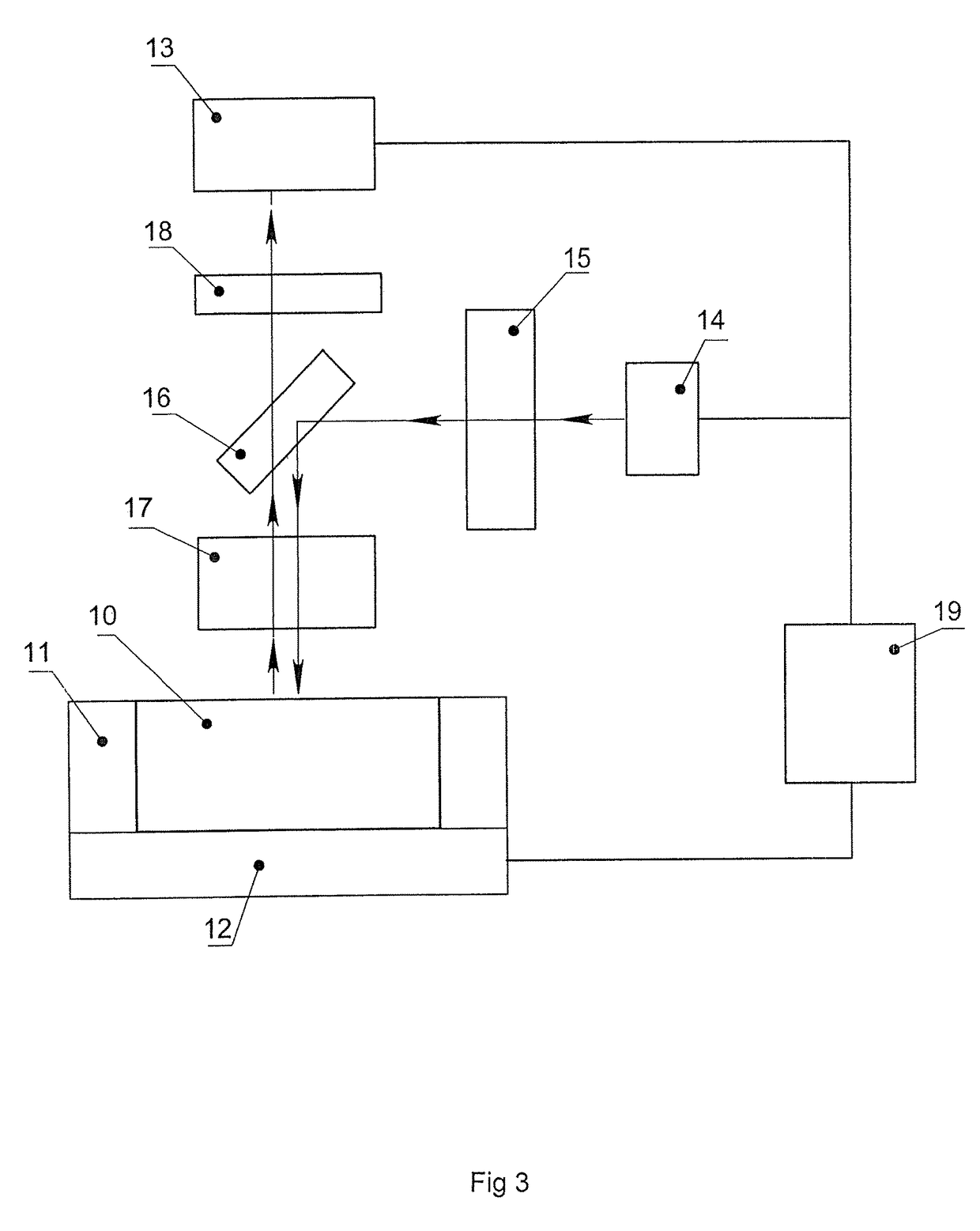

Methods and apparatus are described for the processing (for example washing, incubation, etc.) of particles in which the particles suspended in a first fluid are introduced under laminar flow conditions into at least one first microchamber or first region of the same, in which a second fluid is introduced under laminar flow conditions into at least one second region of the microchamber or of a second microchamber, in such a way as not to mix with the first fluid, and in which at least one field of force acting on the particles is activated in the microchamber(s), to provoke a shift of the particles alone in a predetermined direction and to transfer the same in suspension into the second fluid; an apparatus is preferably used including at least three microchambers n microchambers arranged in sequence with each other in one direction and each connected with the microchamber immediately before it and after it with two orifices offset from each other in a direction perpendicular to the direction of sequence of the microchambers.

Owner:MENARINI SILICON BIOSYSTEMS SPA

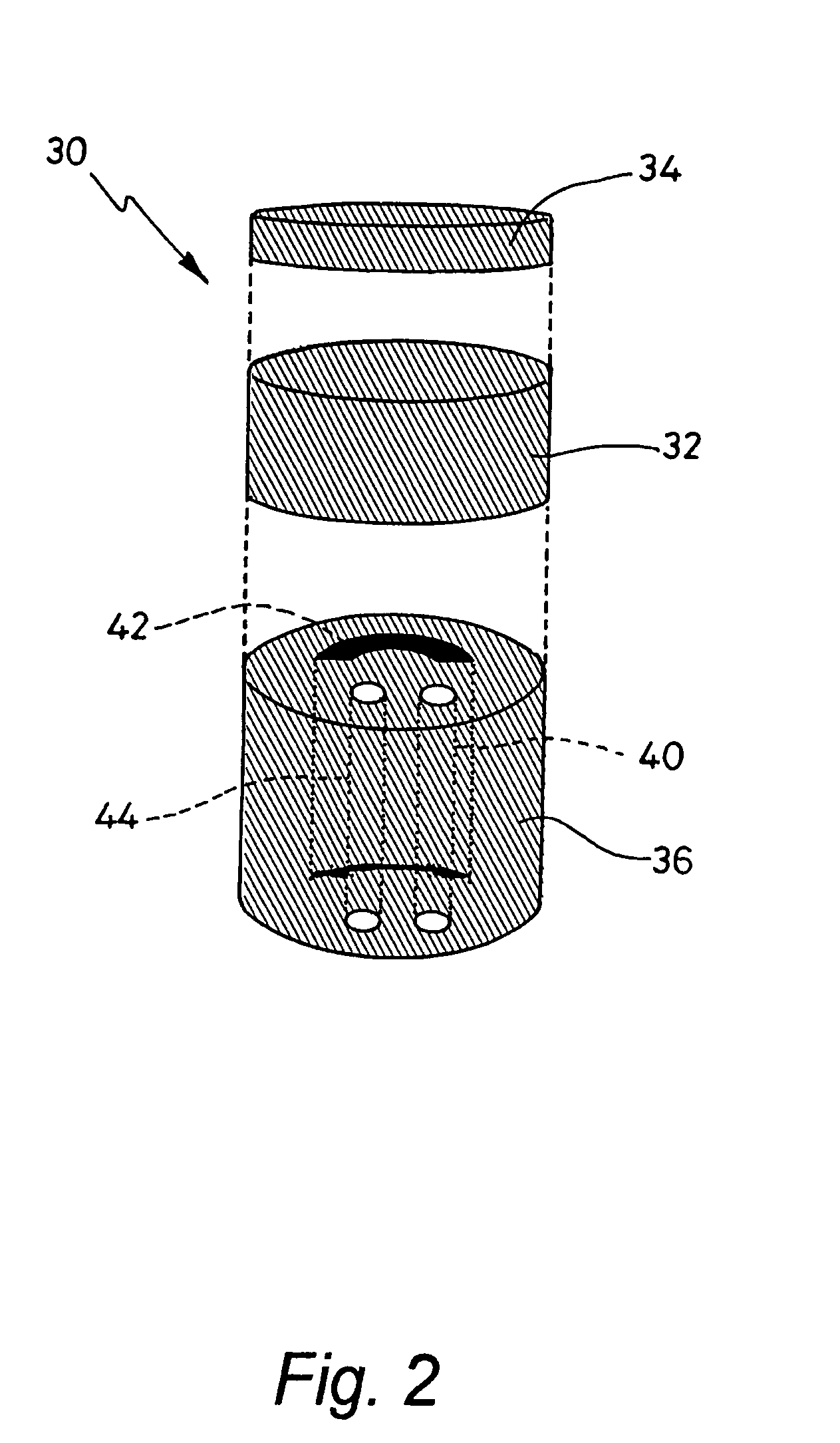

Methods and apparatus for the measurement of hydrogen sulphide and thiols in fuids

InactiveUS20060054501A1Fast response timeReduce reagent consumptionEarth material testingBiological testingThiolRedox

An electrochemical sensor for measuring the amount of hydrogen sulphide or thiols in a fluid comprises an electrically conductive porous electrode within which are dispersed a precursor and a reaction solution which together with the hydrogen sulphide or thiols a redox reaction resulting in an electrical current dependent upon the amount of hydrogen sulphide or thiols in the fluid. The reaction solution may be initially provided in the pores of the porous electrode, or derived in use from the fluid itself.

Owner:SCHLUMBERGER TECH CORP

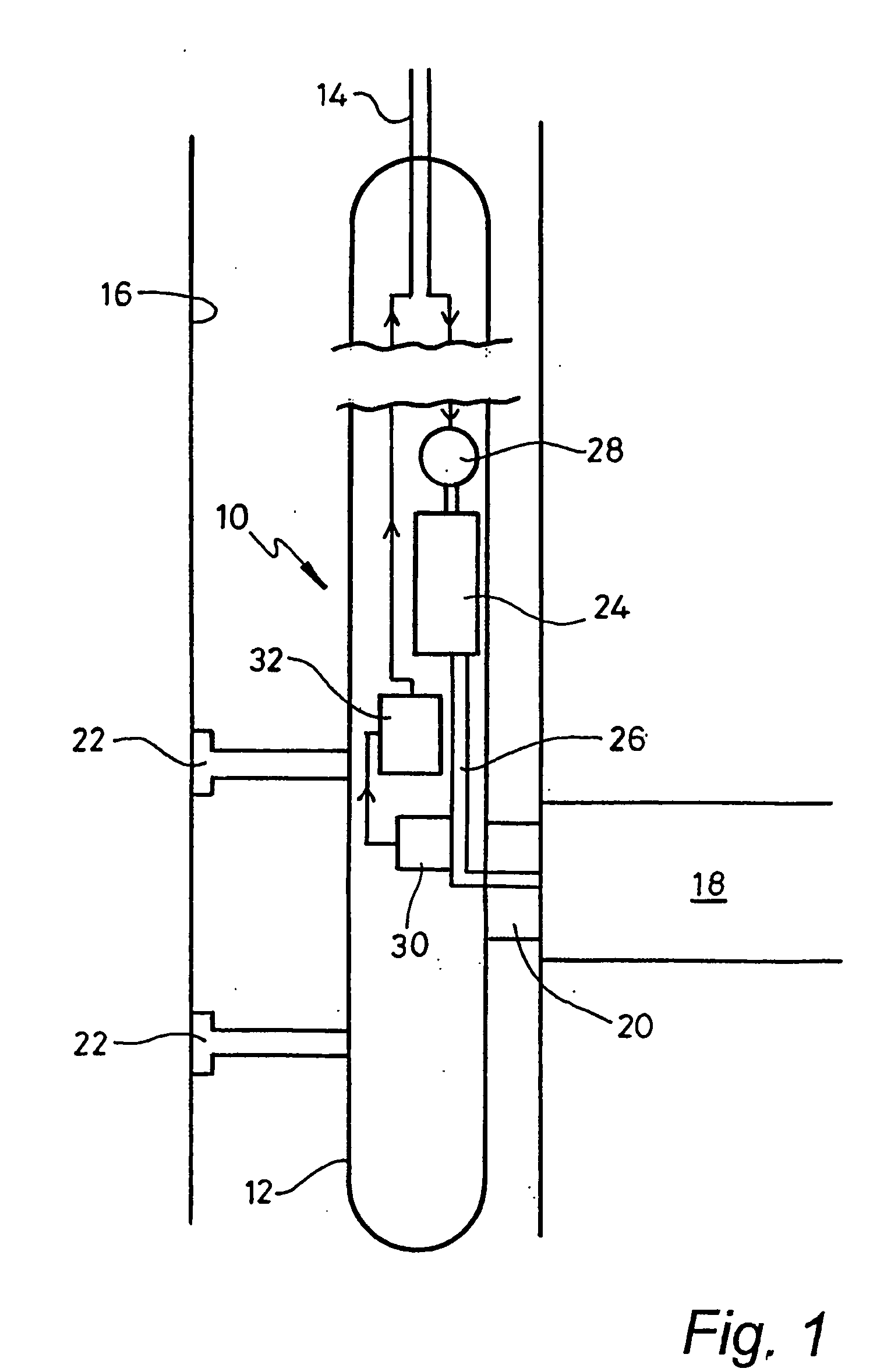

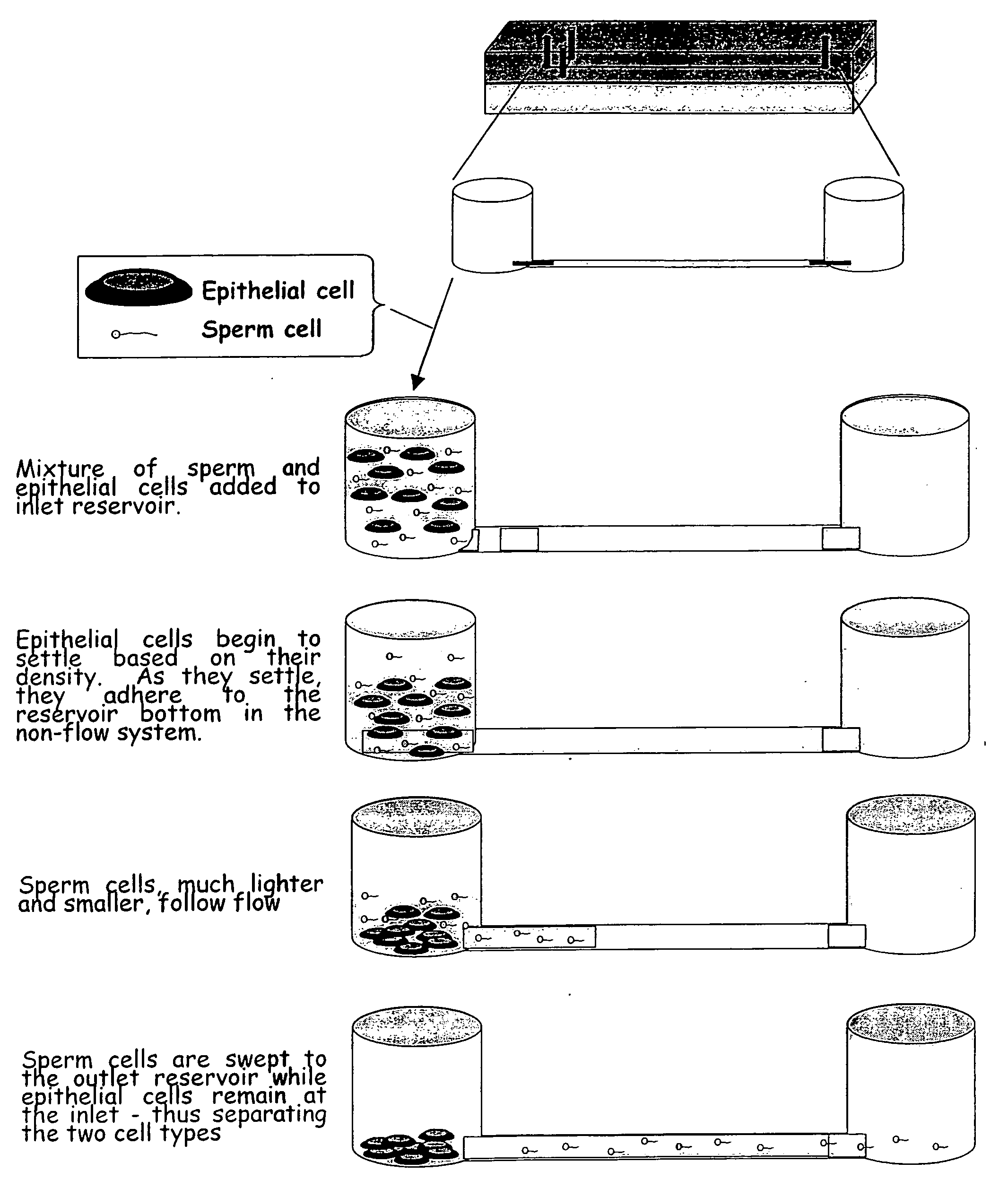

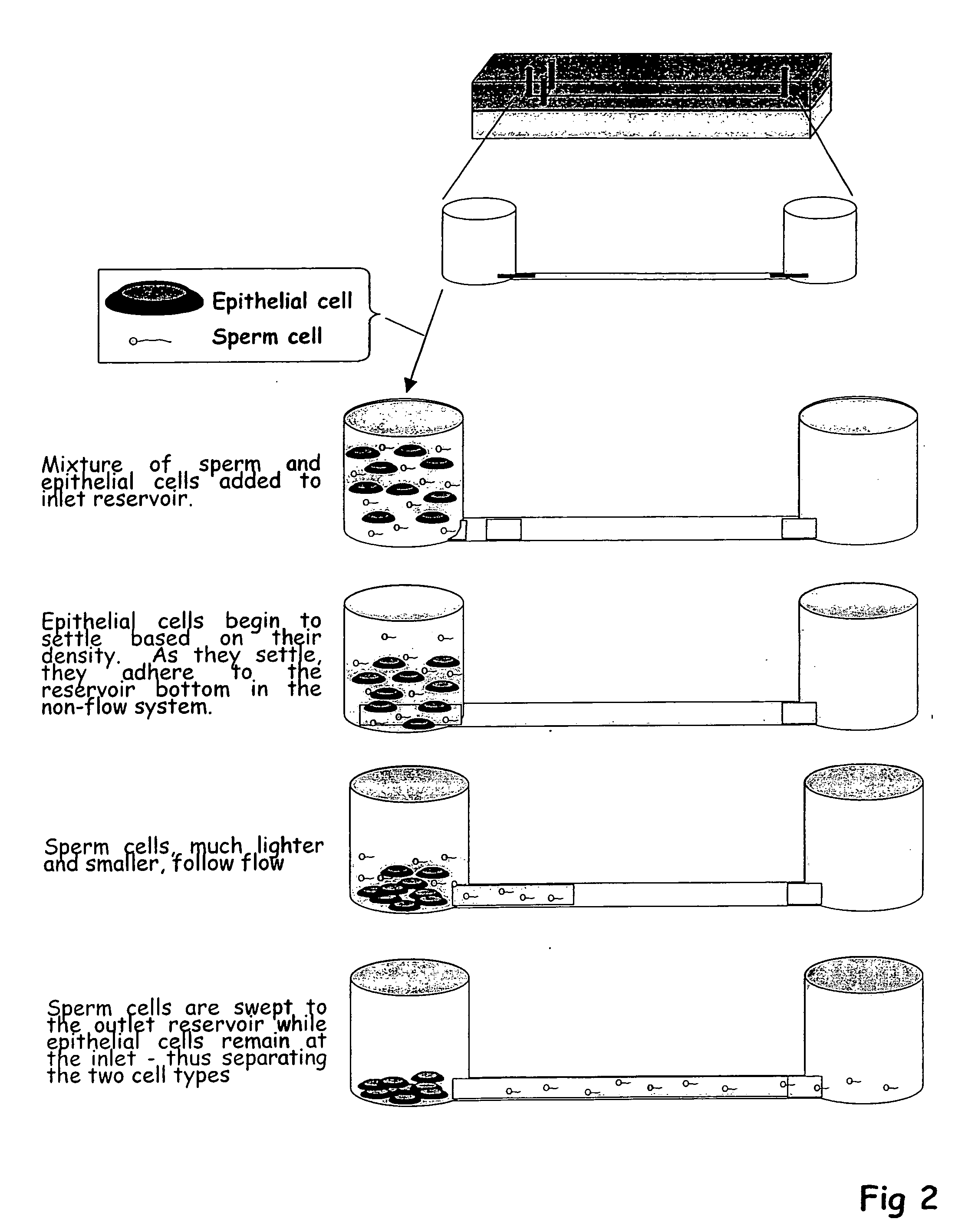

Isolation of sperm cells from other biological materials using microfabricated devices and related methods thereof

InactiveUS20060144707A1Ease of evaluationImprove DNA analysisIon-exchanger regenerationVolume/mass flow measurementBiochemistryCell separation

The present invention relates to cell separation using microfabricated devices. In particular, the present invention provides methods and devices for separation of sperm from biological materials, such as other cells and molecular species, in a cell mixture in a microfabricated device through the use of electroosmotic flow, electrophoretic mobility, pressure gradient, differential adhesion, and / or combinations thereof.

Owner:LANDERS JAMESP +2

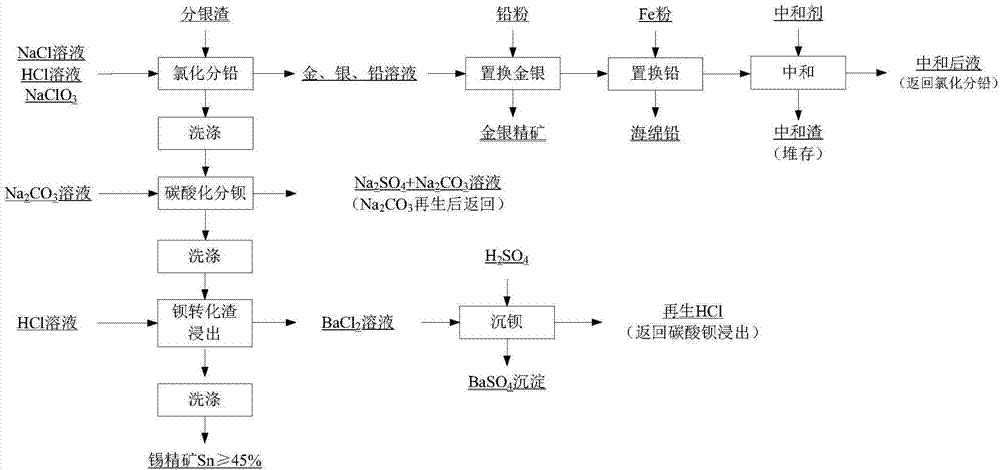

Method for step-by-step extraction of copper anode mud silver separating residues

ActiveCN106967884AEfficient separationReduce reagent consumptionProcess efficiency improvementSolution systemCarbonic acid

The invention discloses a method for step-by-step extraction of copper anode mud silver separating residues and belongs to the technical field of copper smelting comprehensive recovery. By means of the method, chlorine salt is used for separating gold, silver and lead, barium is separated through carbonic acid conversion-hydrochloric acid leaching, and separation of lead, barium, gold and silver and efficient concentration of tin are effectively achieved; and environment-friendly and efficient recovery of metal such as Au, Ag, Pb, Sn and Ba in the silver separating residues is successfully achieved. Meanwhile, effective solution system circulation of chlorination solution circulation, carbonic acid solution circulation and HCl regeneration circulation is developed for a lead and barium separation system, and consumption of a reagent is greatly reduced. By means of the method, technology conditions are moderate, high temperatures, high acid and strong base are not needed, and the large-scale industry is better achieved; due to self circulation of different solution systems, outward draining of waste water is avoided, all components in the silver separating residues are recycled, solid waste is prevented from being generated, and environment friendliness is achieved.

Owner:北矿力澜科技咨询(北京)有限公司

Analytical test element and method for blood analyses

InactiveUS7641862B2Little interactionReduce reagent consumptionBioreactor/fermenter combinationsBiological substance pretreatmentsBlood gas analysis% total haemoglobin

An analytical test element for blood analyses is provided having an application site and a microfluidic channel structure in fluid communication with the application site. The channel structure includes at least first and second analytical channels for receiving first and second portions of a blood sample applied to the application site. The first analytical channel includes a first analytical site to determine the total haemoglobin value (Hb) of the blood sample. The second analytical channel includes a second analytical site to determine a glycohaemoglobin value (HbA1c) of the blood sample.

Owner:ROCHE DIAGNOSTICS OPERATIONS INC

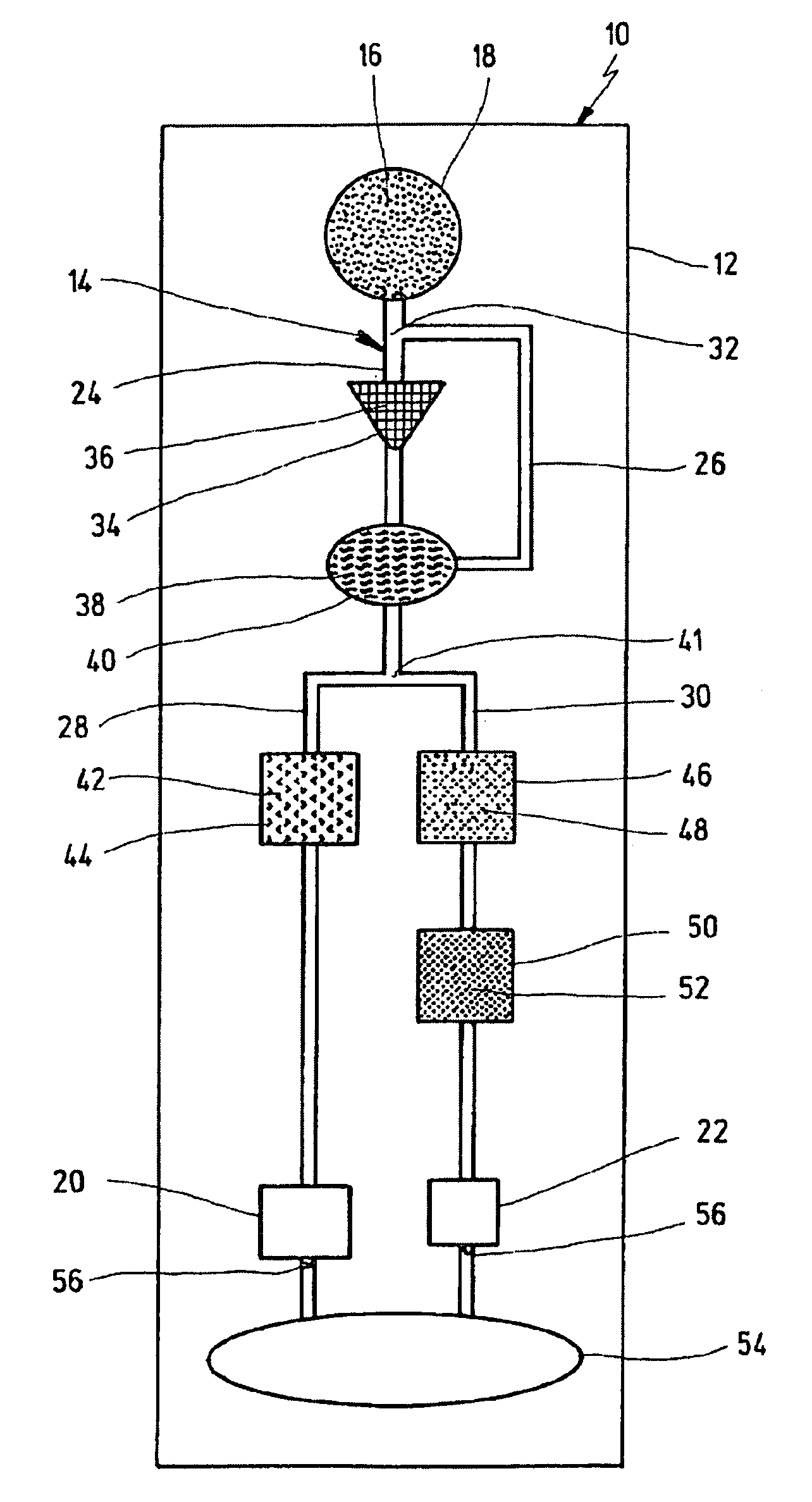

Method used for extracting uranium and niobium from low-grade ore

The invention provides a method used for integrated extraction separation of uranium and niobium from low-grade ore. The method comprises following steps: 1, ore containing uranium and niobium is grinded; 2, grinded ore is mixed with concentrated sulfuric acid at a certain mass ratio, and an obtained mixture is subjected to roasting for 0.5 to 6h at 150 to 300 DEG C; 3, a clinker obtained via roasting is subjected to leaching with a 0 to 20wt% sulfuric acid solution, leach slurry is subjected to filtering and washing so as to obtain a filtrate containing uranium and niobium; 4, P2O4, TBP, P311, and sulfonated kerosene mixed organic phase are subjected to synergistic extraction of uranium in the filtrate, a uranium-containing organic phase is subjected to reextraction with a 8wt% to 15wt% Na2CO3 solution, and an obtained reextraction qualified liquid is subjected to precipitation with NaOH so as to obtain '111' products; and 5, after uranium extraction, an obtained solution is delivered into an autoclave, and is subjected to reaction at 110 to 200 DEG C under a pressure maintained to be 0.14 to 1.55MPa, and cooling filtering is carried out so as to obtain a niobium-containing precipitate and a niobium precipitation mother liquor, and then the niobium precipitation mother liquor is recycled to leaching. The method is capable of solving problems that uranium-containing low-grade niobium ore comprehensive extraction and recycling are difficult to realize, metal recovery rate is high, and processing treatment cost is low.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

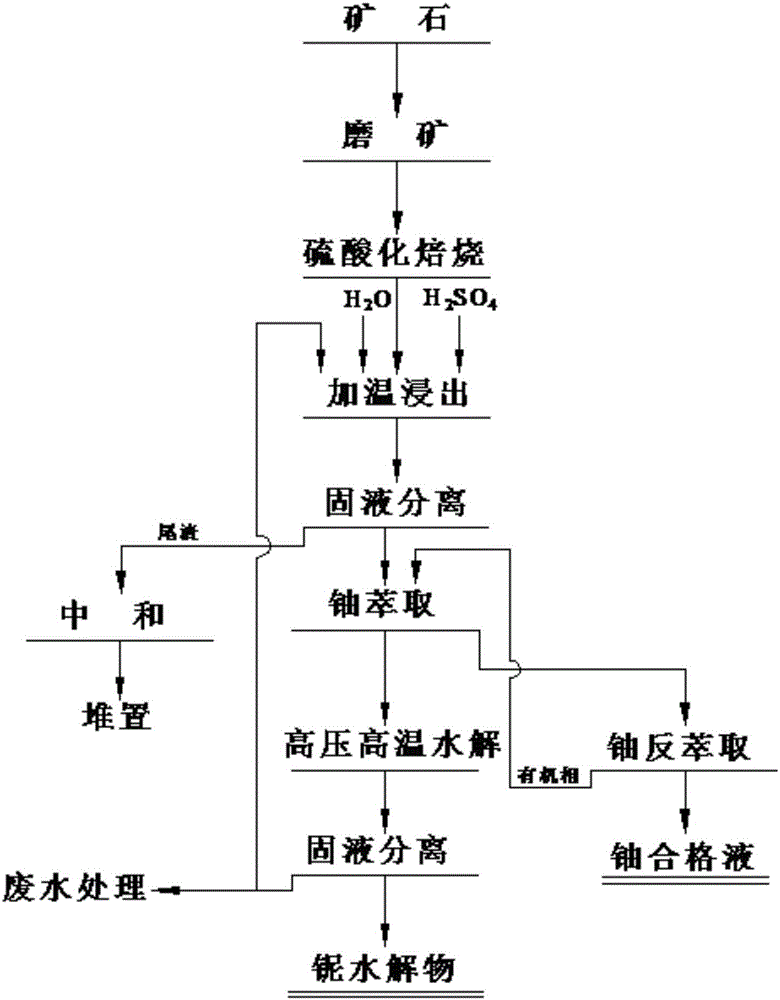

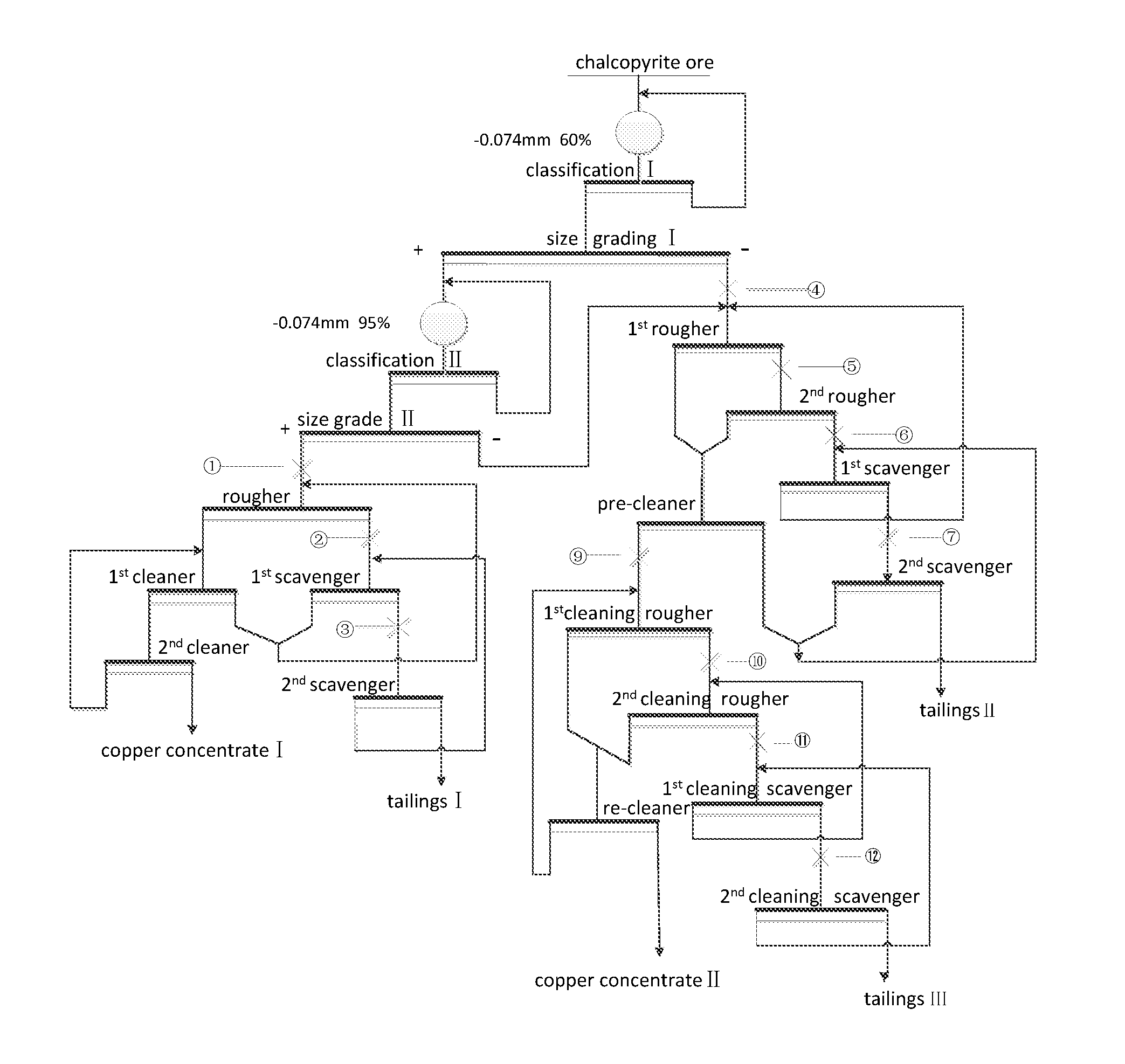

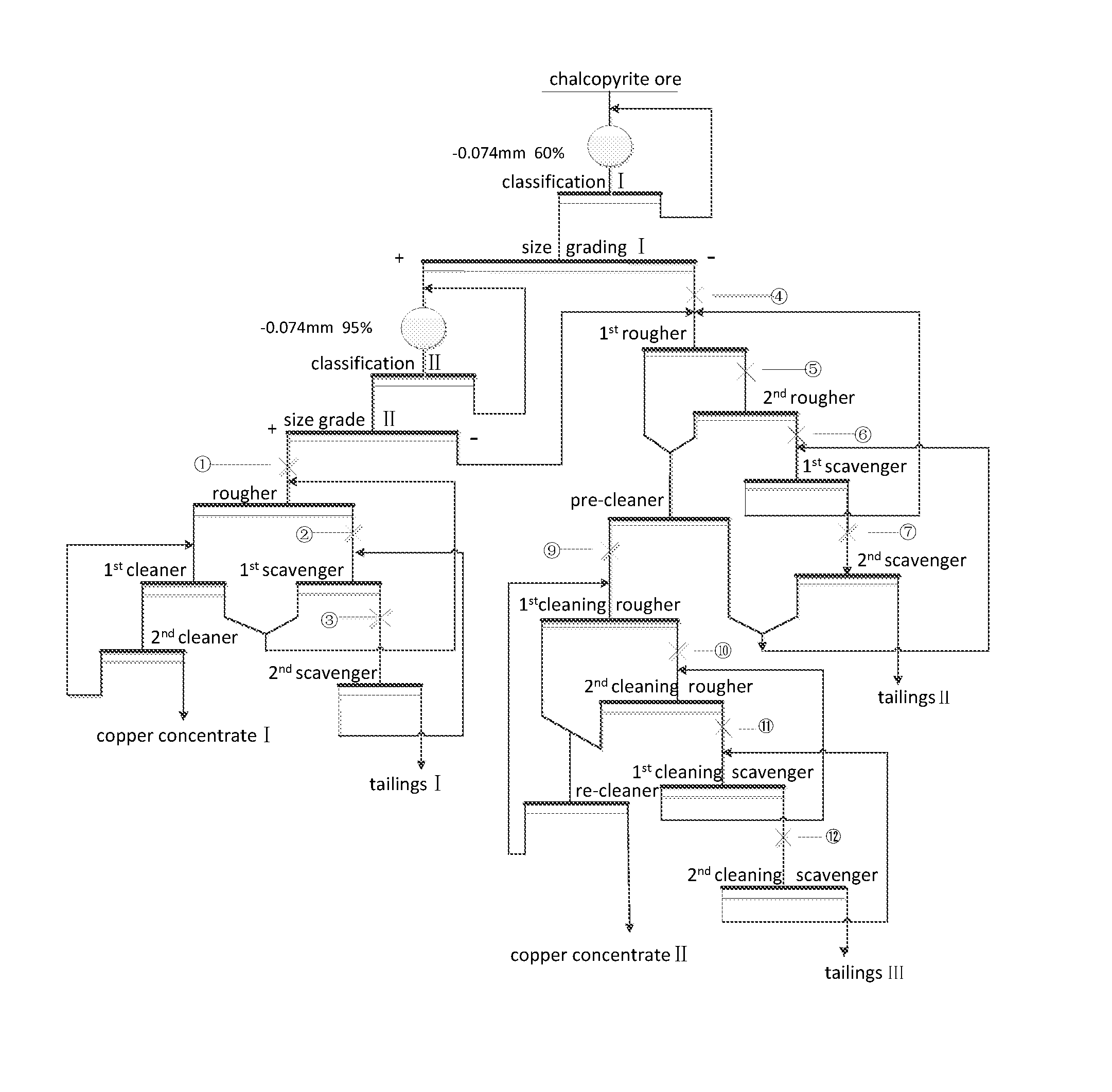

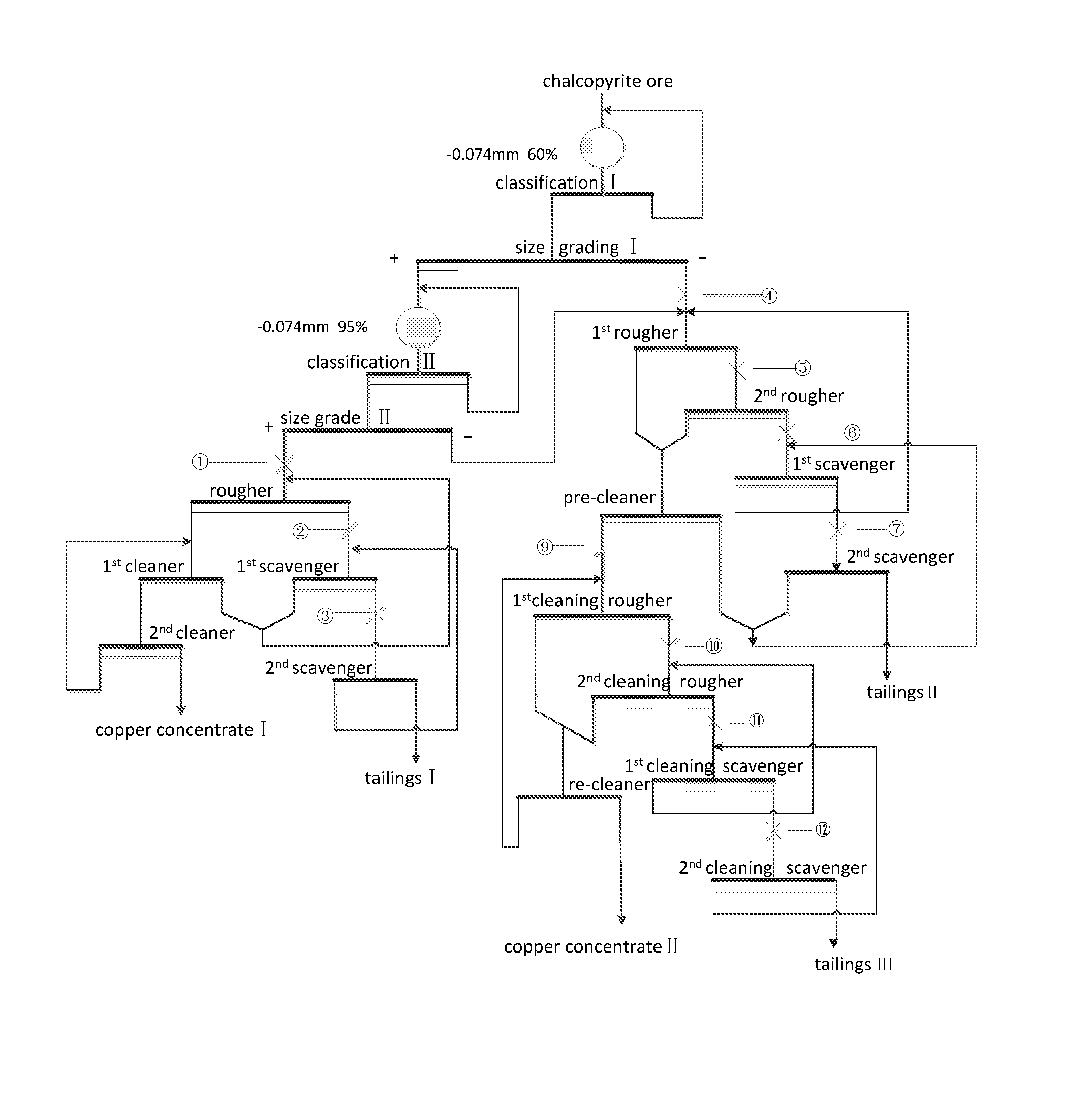

Chalcopyrite ore beneficiation process and method

The present invention relates to a mineral processing technology and method for refractory chalcopyrite ores, particularly to a mineral processing technology and method for the separation of chalcopyrite from multiple natural types of copper ores containing chalcopyrite, pyrrhotite, talc and serpentine, which belongs to the technical field of mineral processing. It's characterized by: conducting a two-stage grinding on the chalcopyrite ore, with each grinding stage followed by size grading, and treating ores in different size fractions separately, wherein coarse-grain ores are separated in the presence of xanthate, with calcium oxide and CMC controlling the pH and acting as depressor respectively, while fine-grained ores are subjected to rougher in the presence of kerosene, and subsequently subjected to cleaner in the presence of xanthate.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Analysis

InactiveUS20090203022A1No added complexitySimple processBioreactor/fermenter combinationsBiological substance pretreatmentsComputer science

Owner:WHITESPACE ENTERPRISE

Chalcopyrite ore beneficiation process and method

InactiveUS20160158767A1Reduce the impactEffective selective separationFlotationGrain treatmentsKeroseneTalc

The present invention relates to a mineral processing technology and method for refractory chalcopyrite ores, particularly to a mineral processing technology and method for the separation of chalcopyrite from multiple natural types of copper ores containing chalcopyrite, pyrrhotite, talc and serpentine, which belongs to the technical field of mineral processing. It's characterized by: conducting a two-stage grinding on the chalcopyrite ore, with each grinding stage followed by size grading, and treating ores in different size fractions separately, wherein coarse-grain ores are separated in the presence of xanthate, with calcium oxide and CMC controlling the pH and acting as depressor respectively, while fine-grained ores are subjected to rougher in the presence of kerosene, and subsequently subjected to cleaner in the presence of xanthate.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Analytical Test Element and Method for Blood Analyses

InactiveUS20090087901A1Little interactionReduce reagent consumptionBioreactor/fermenter combinationsBiological substance pretreatmentsMedicine% total haemoglobin

An analytical test element for blood analyses is provided having an application site and a microfluidic channel structure in fluid communication with the application site. The channel structure comprises at least first and second analytical channels for receiving first and second portions of a blood sample applied to the application site. The first analytical channel comprises a first analytical site to determine the total haemoglobin value (Hb) of the blood sample. The second analytical channel comprises a second analytical site to determine a glycohaemoglobin value (HbA1c) of the blood sample.

Owner:ROCHE DIAGNOSTICS OPERATIONS INC

Method and apparatus for the processing and/or analysis and/or selection of particles, in particular biological particles

ActiveUS8679856B2Reduce reagent consumptionEasy to moveBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringBiological particles

Methods and apparatus are described for the processing (for example washing, incubation, etc.) of particles in which the particles suspended in a first fluid are introduced under laminar flow conditions into at least one first microchamber or first region of the same, in which a second fluid is introduced under laminar flow conditions into at least one second region of the microchamber or of a second microchamber, in such a way as not to mix with the first fluid, and in which at least one field of force acting on the particles is activated in the microchamber(s), to provoke a shift of the particles alone in a predetermined direction and to transfer the same in suspension into the second fluid; an apparatus is preferably used including at least three microchambers n microchambers arranged in sequence with each other in one direction and each connected with the microchamber immediately before it and after it with two orifices offset from each other in a direction perpendicular to the direction of sequence of the microchambers.

Owner:MENARINI SILICON BIOSYSTEMS SPA

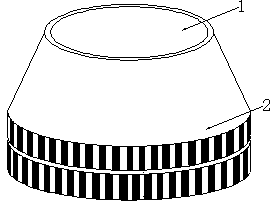

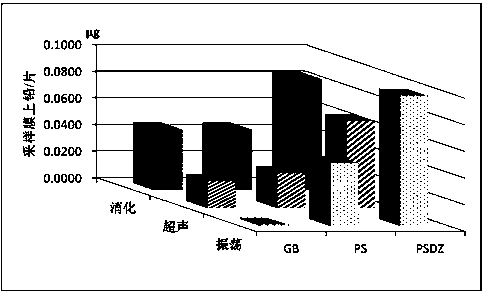

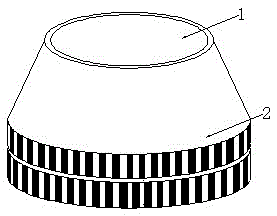

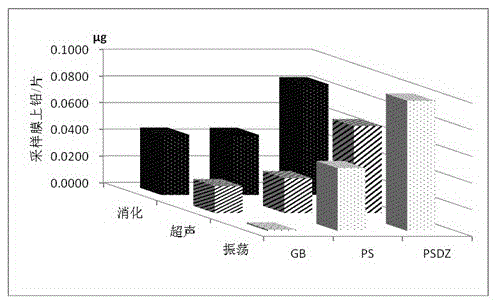

Sampling membrane and sampler capable of enriching heavy metals in ambient air and application method of sampler

The invention discloses a sampling membrane and a sampler capable of enriching heavy metals in ambient air and an application method of the sampler. The sampling membrane comprises a nanometer fiber membrane and an air-permeable supporting padding arranged below the nanometer fiber membrane. The sampler comprises the sampling membrane and a sampling clamp; the sampling clamp is composed of an upper cone and a lower cylinder, wherein the upper surface of the cone is horizontal, the cylinder is composed of an upper cylinder and a rotary lower cylinder, the side surfaces of the upper cylinder and the lower cylinder are provided with uniformly distributed vertical ridges, the vertical ridges on the upper cylinder and the lower cylinder are aligned by rotating the lower cylinder, so fixation of the sampling membrane on the horizontal surface of the sampling clamp is realized. After heavy metals in air are acquired by using the sampler, a filter membrane is taken out and put into a centrifuge tube filled with a buffer solution, a solution is used for desorption of the heavy metals on the filter membrane, and after desorption, the solution is determined. According to the invention, detection sensitivity can be substantially improved, pre-treatment of a sample is easy and feasible, and nanometer fiber filter membranes with different functions are used for different detection objects, thereby improving absorption and acquisition efficiency.

Owner:SOUTHEAST UNIV +1

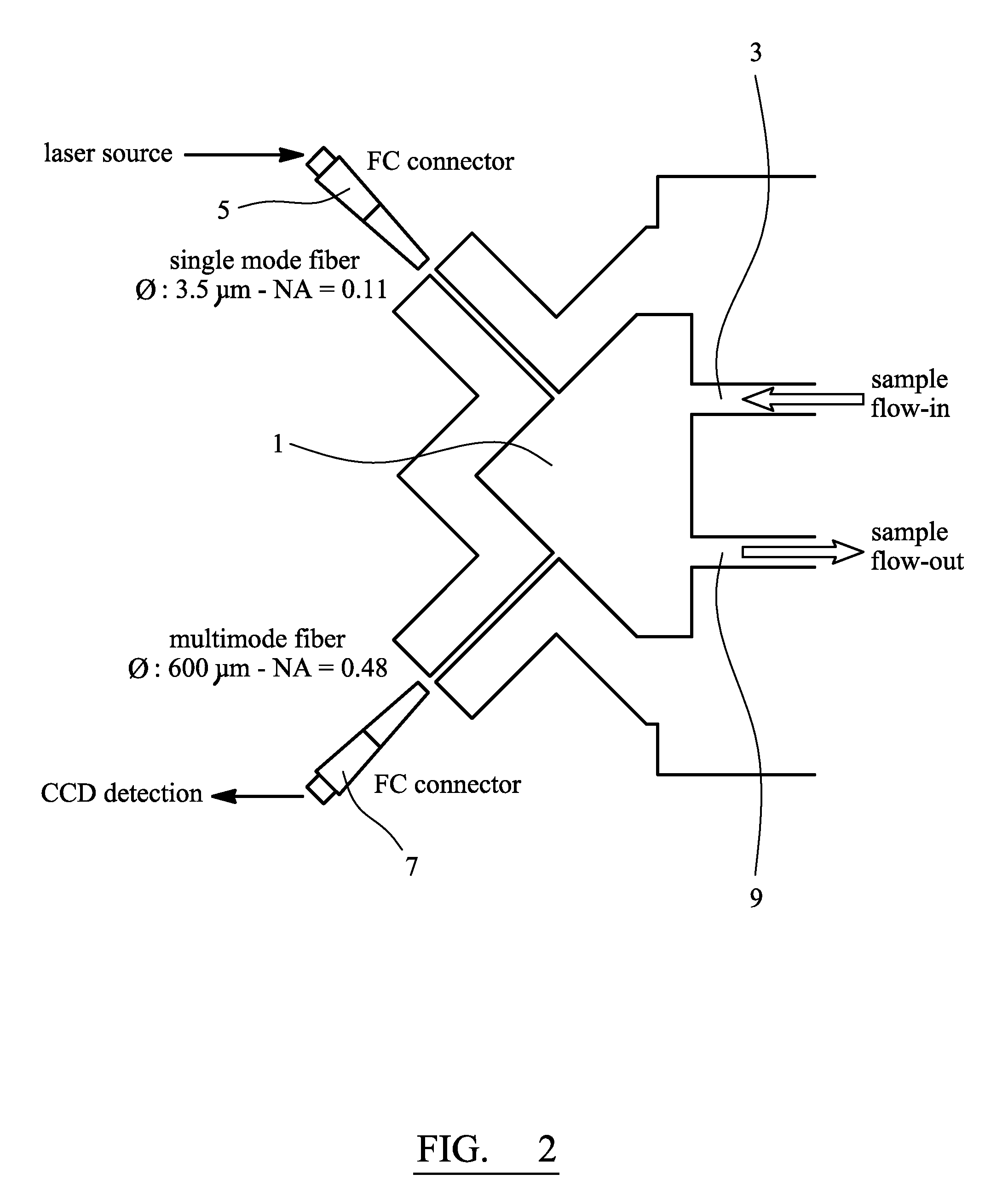

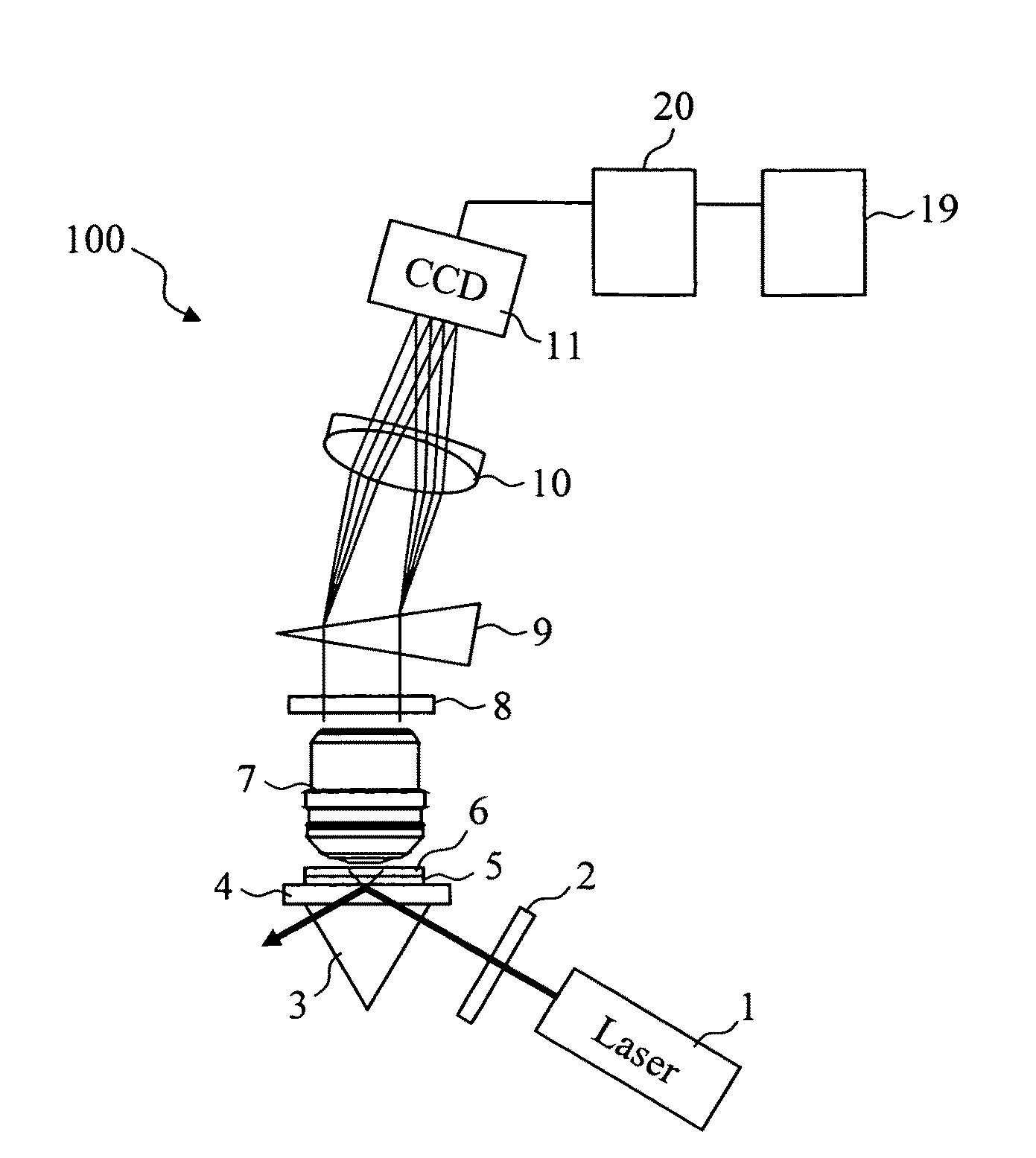

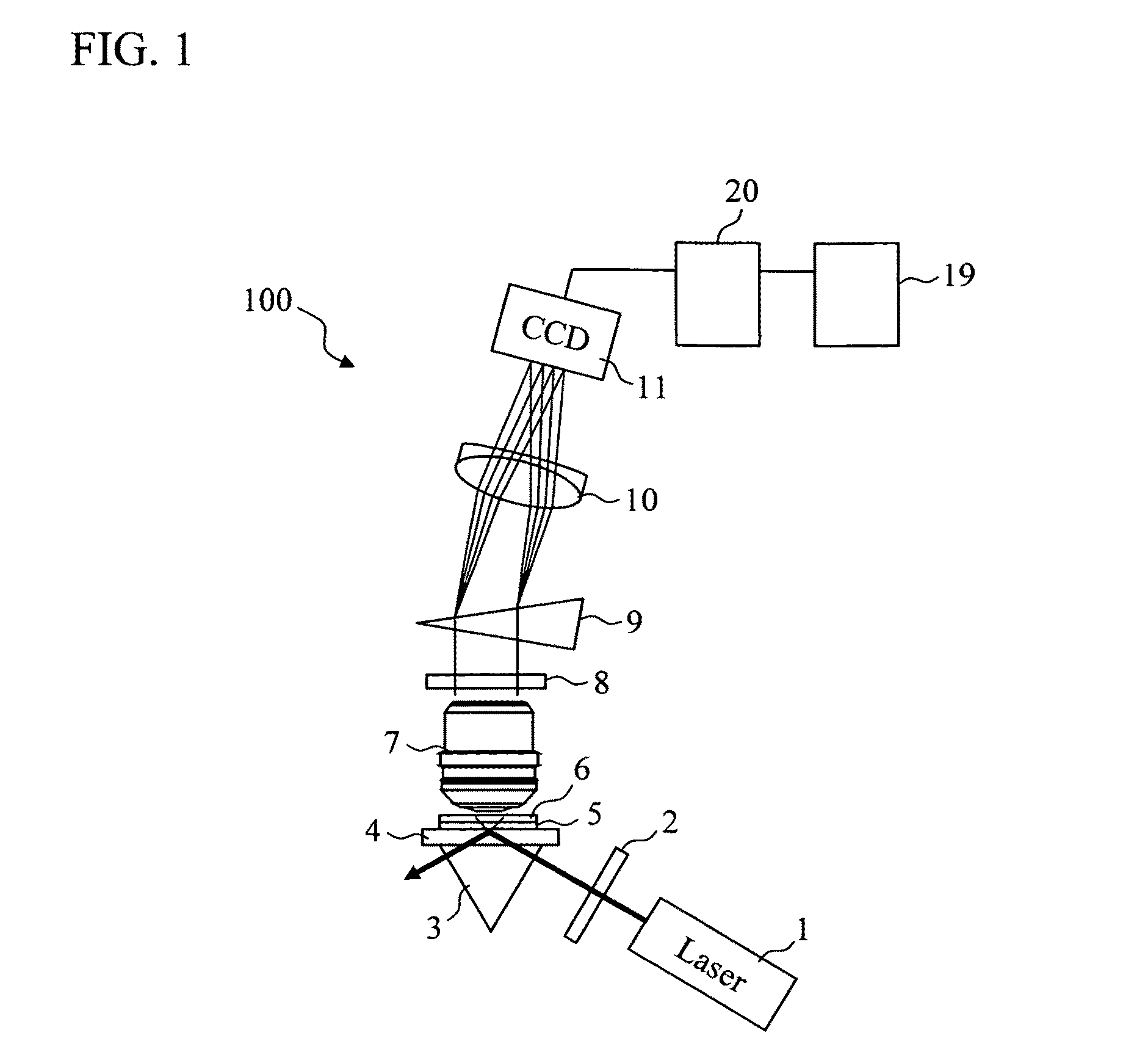

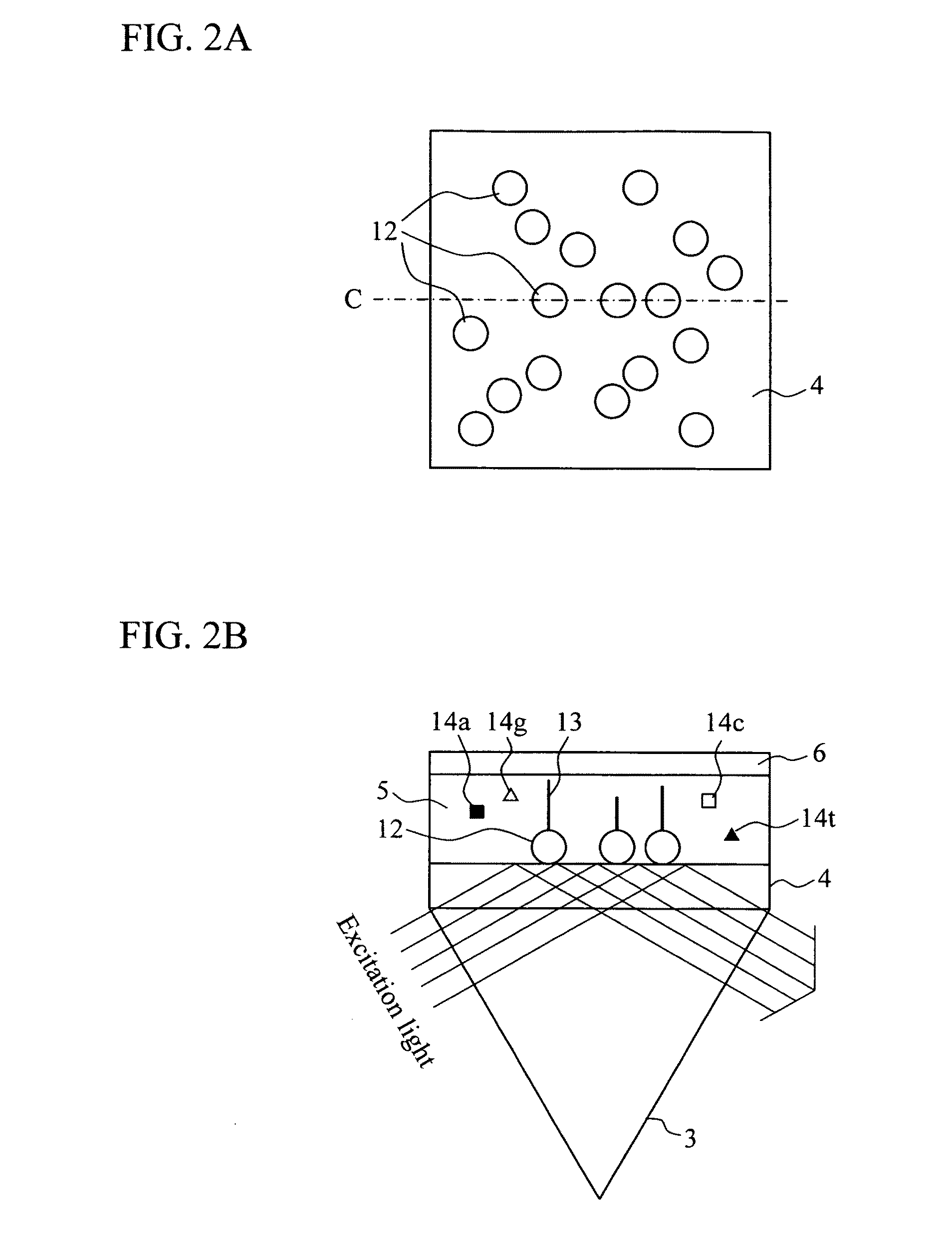

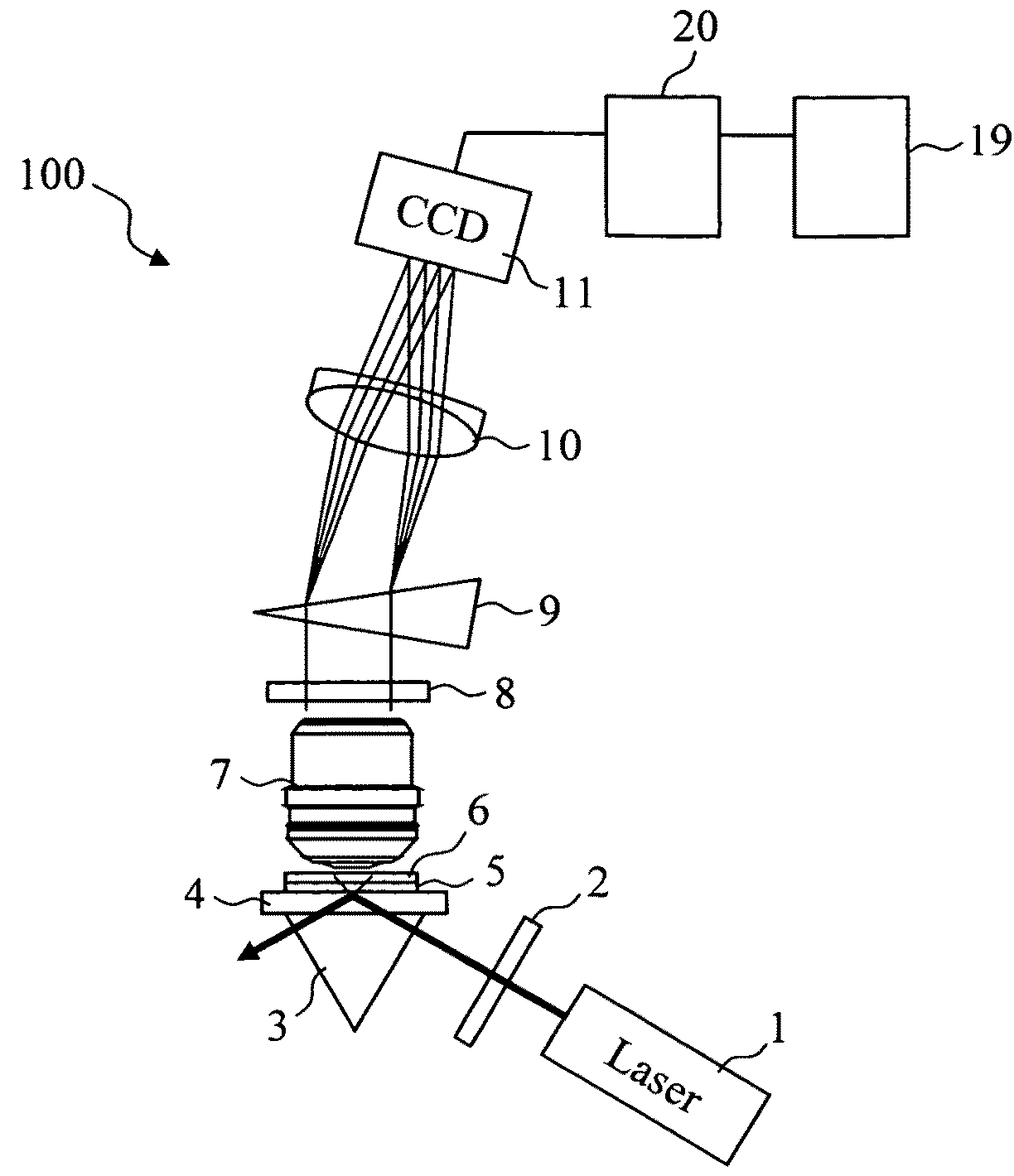

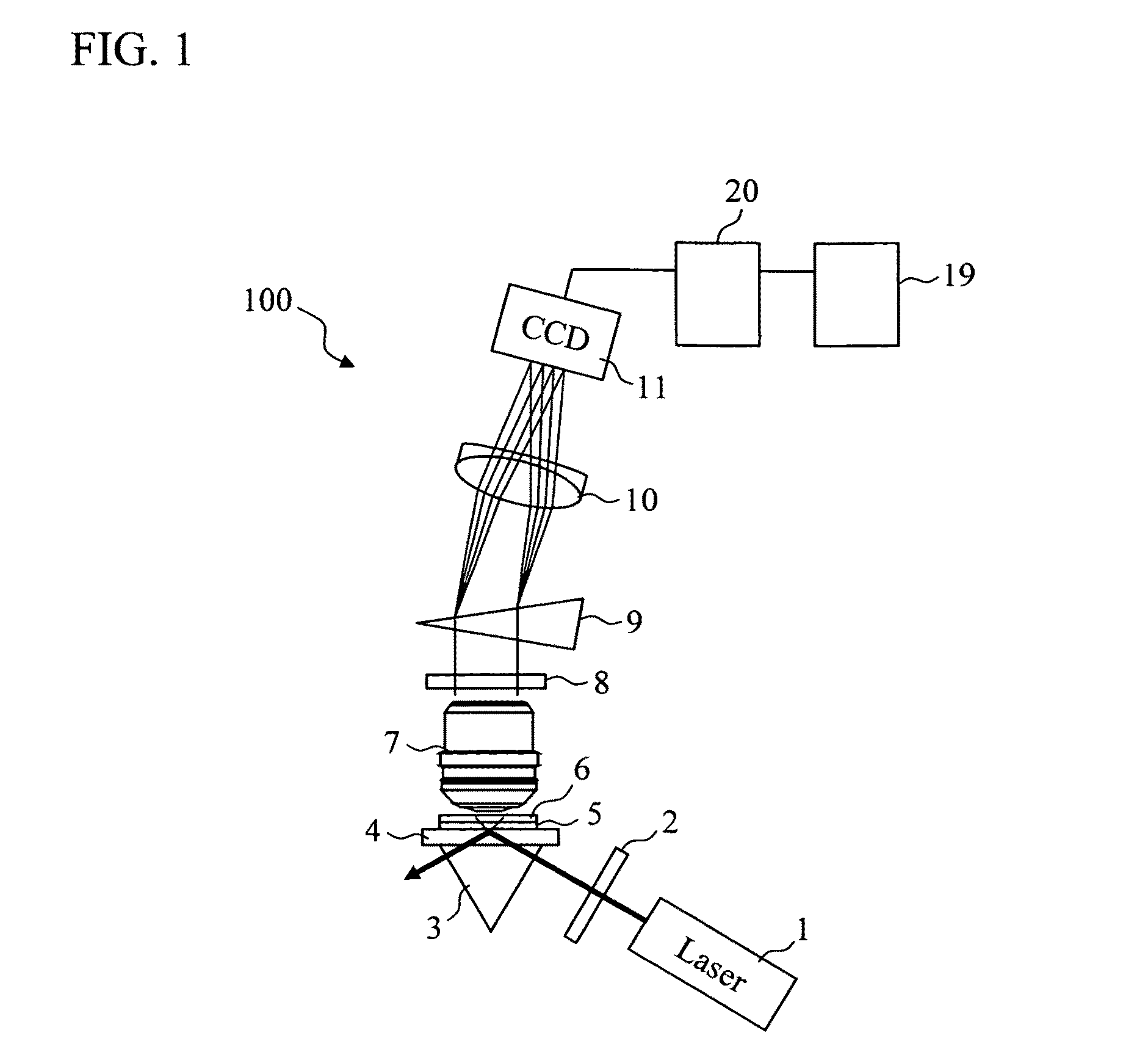

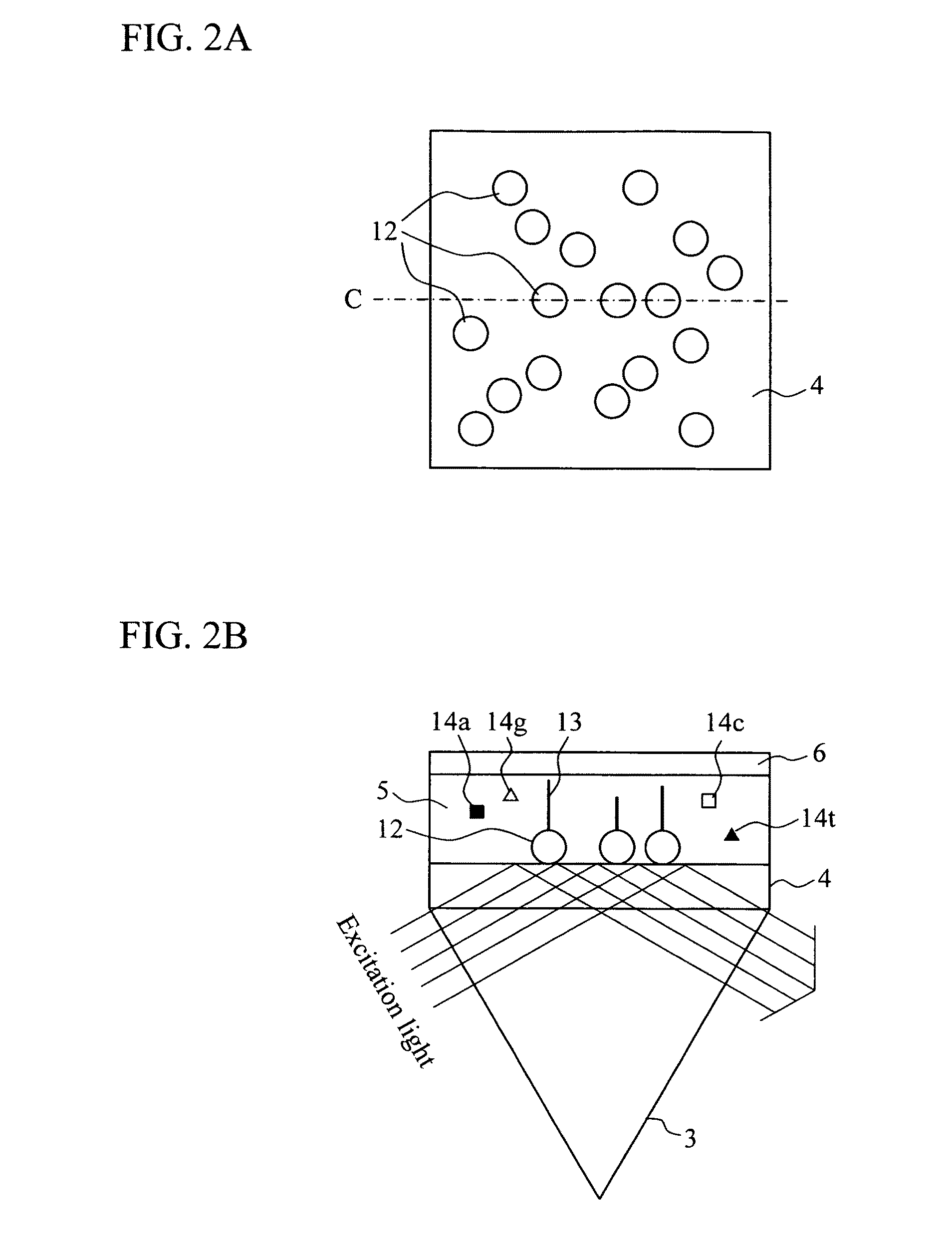

Photometric instrument

InactiveUS20090128807A1Minimal timeReduce reagent consumptionRadiation pyrometrySpectrum investigationParticulatesPhotoluminescence

A metallic structure is provided on a surface of a substrate. A component having a longer wavelength than excitation light is detected from luminescence from fixation positions of biomolecules and emitted from a material other than the biomolecules, and is used for photometrical analysis. As the structure, usable is a particulate (a metallic structure of a size not larger than a wavelength of the excitation light), a minute protrusion, or a thin film with minute apertures, which are made of a metal such as gold, chrome, silver or aluminum. In the case of the particulate or the minute protrusion, photoluminescence of the structure is detected with a biomolecule being fixed thereon. In the case of the thin film with minute apertures, Raman scattered light of specimen solution around the biomolecules, and photoluminescence of the metallic structure near the biomolecules are detected with biomolecules being fixed in the apertures.

Owner:HITACHI HIGH-TECH CORP

Apparatus and method for recovering rare-earth and noble metals from an article

InactiveUS20070104628A1Easily enlargedImprove productivityGaseous chemical processesLiquid-gas reaction of thin-film typeInterior spaceRare earth

An apparatus for recovering a target metal from an article. The apparatus includes a reaction chamber defining an interior space; an evaporator coupled to the reaction chamber, a condenser within the reaction chamber, and a solution recovery portion within the reaction chamber and separate from the evaporator. With the apparatus, an oxidizing solution is converted into a vaporized oxidizer; the article is exposed to the vaporized oxidizer for interaction with the target metal; the vaporized oxidizer is condensed into a condensed solution that removes the target metal from the article; and a concentrated solution comprising the condensed solution and the target metal is collected separate from the oxidizing solution. After the concentrated solution is collected, the target metal can be separated therefrom through any number of known processes.

Owner:OSBORNE FRANK

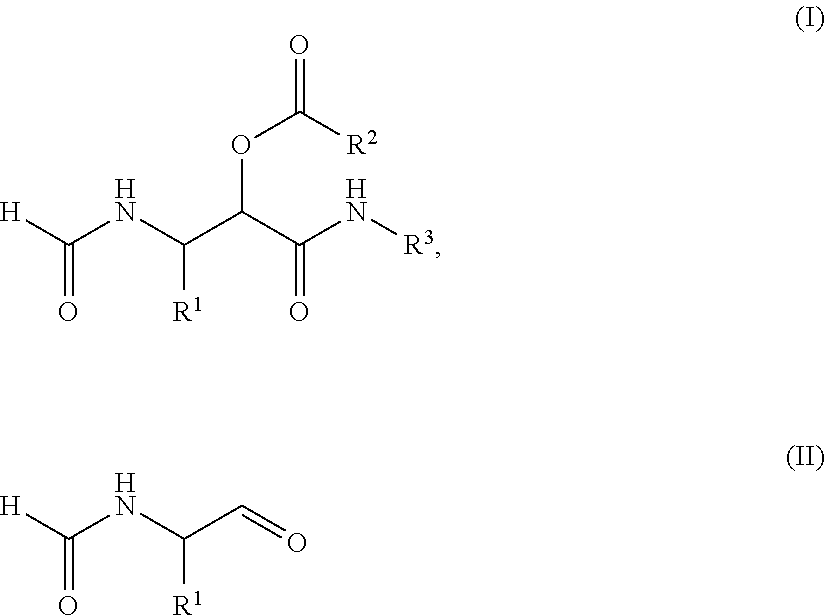

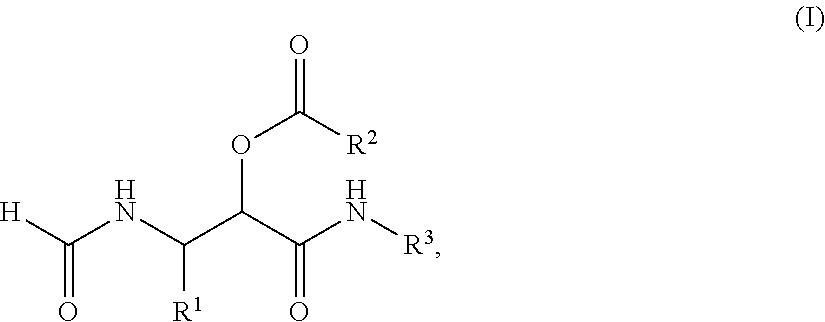

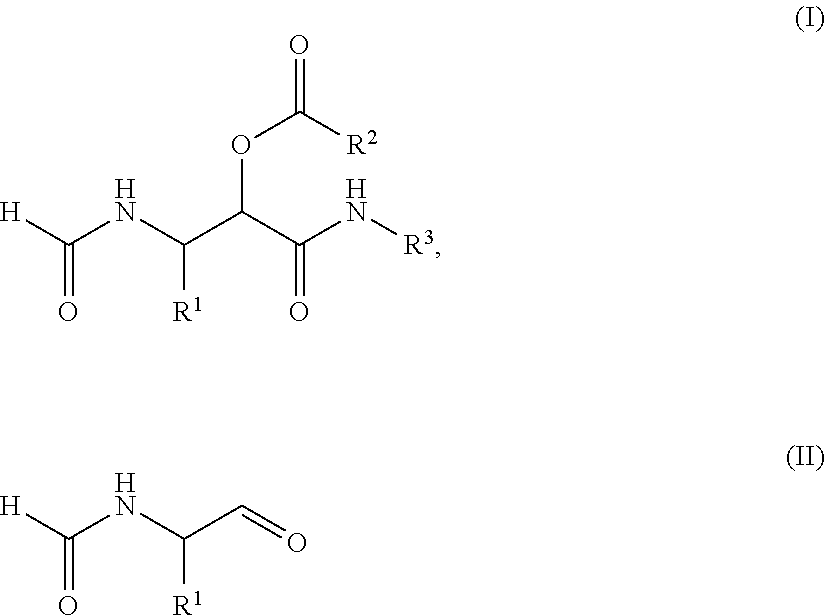

PROCESS FOR THE PREPARATION OF alpha-ACYLOXY beta-FORMAMIDO AMIDES

InactiveUS20120330015A1High yieldImprove efficiencyIsocyanic acid derivatives preparationOrganic compound preparationDipeptideTricyclic

The present invention relates to a process for the preparation of a compound of the general Formula (I), comprising: a) reacting a compound of the general Formula (II) with a compound of the Formula III R2COOH and a compound of the general Formula IV R3NC under such conditions that compound I is formed, wherein R1 represents a substituted or unsubstituted alkyl, alkenyl, alkynyl, aromatic or non-aromatic, mono-, di- or tricyclic, or heterocyclic structure, and R2 represents a substituted or unsubstituted alkyl, alkenyl, alkynyl, aromatic or non-aromatic, mono-, di- or tricyclic, or heterocyclic structure, and R3 represents a substituted or unsubstituted alkyl, alkenyl, or alkynyl structure. In further aspect the subject invention relates to the use of the obtained products as intermediates for various peptidomimetics, and preferably as a building block in a convergent synthesis of prolyl dipeptide structures.

Owner:VER VOOR CHRISTELIJK HOGER ONDERWIJS WETENSCHAPPELIJK ONDERZOEK & PATIENTENZORG TECH TRANSFER OFFICE VU & VUMC

Process for the preparation of α-acyloxy β-formamido amides

InactiveUS8686145B2Improve efficiencyHigh yieldIsocyanic acid derivatives preparationOrganic compound preparationDipeptideMedicinal chemistry

The present invention relates to a process for the preparation of a compound of the general Formula (I), comprising: a) reacting a compound of the general Formula (II) with a compound of the Formula III R2COOH and a compound of the general Formula IV R3NC under such conditions that compound I is formed, wherein R1 represents a substituted or unsubstituted alkyl, alkenyl, alkynyl, aromatic or non-aromatic, mono-, di- or tricyclic, or heterocyclic structure, and R2 represents a substituted or unsubstituted alkyl, alkenyl, alkynyl, aromatic or non-aromatic, mono-, di- or tricyclic, or heterocyclic structure, and R3 represents a substituted or unsubstituted alkyl, alkenyl, or alkynyl structure. In further aspect the subject invention relates to the use of the obtained products as intermediates for various peptidomimetics, and preferably as a building block in a convergent synthesis of prolyl dipeptide structures.

Owner:VER VOOR CHRISTELIJK HOGER ONDERWIJS WETENSCHAPPELIJK ONDERZOEK & PATIENTENZORG TECH TRANSFER OFFICE VU & VUMC

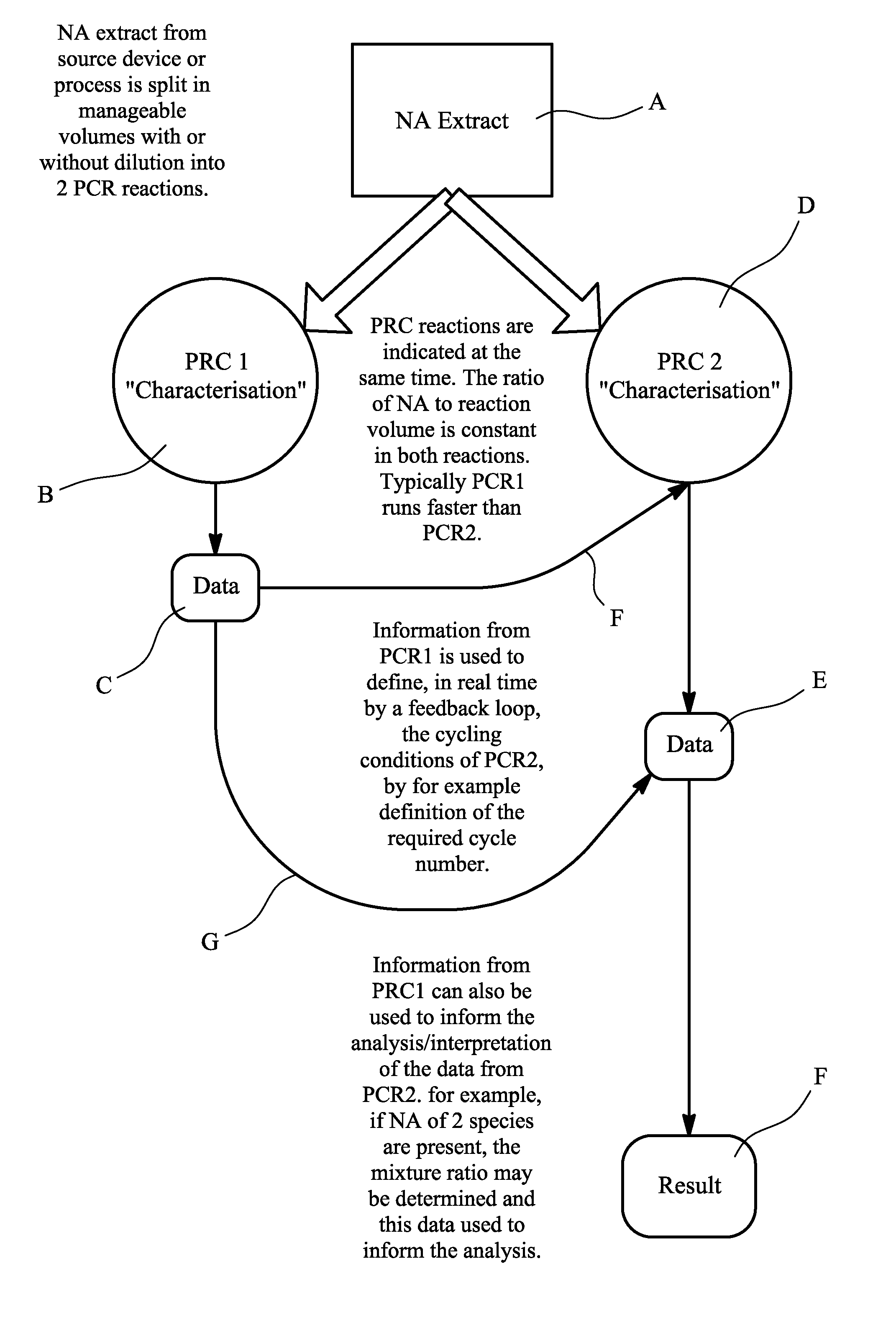

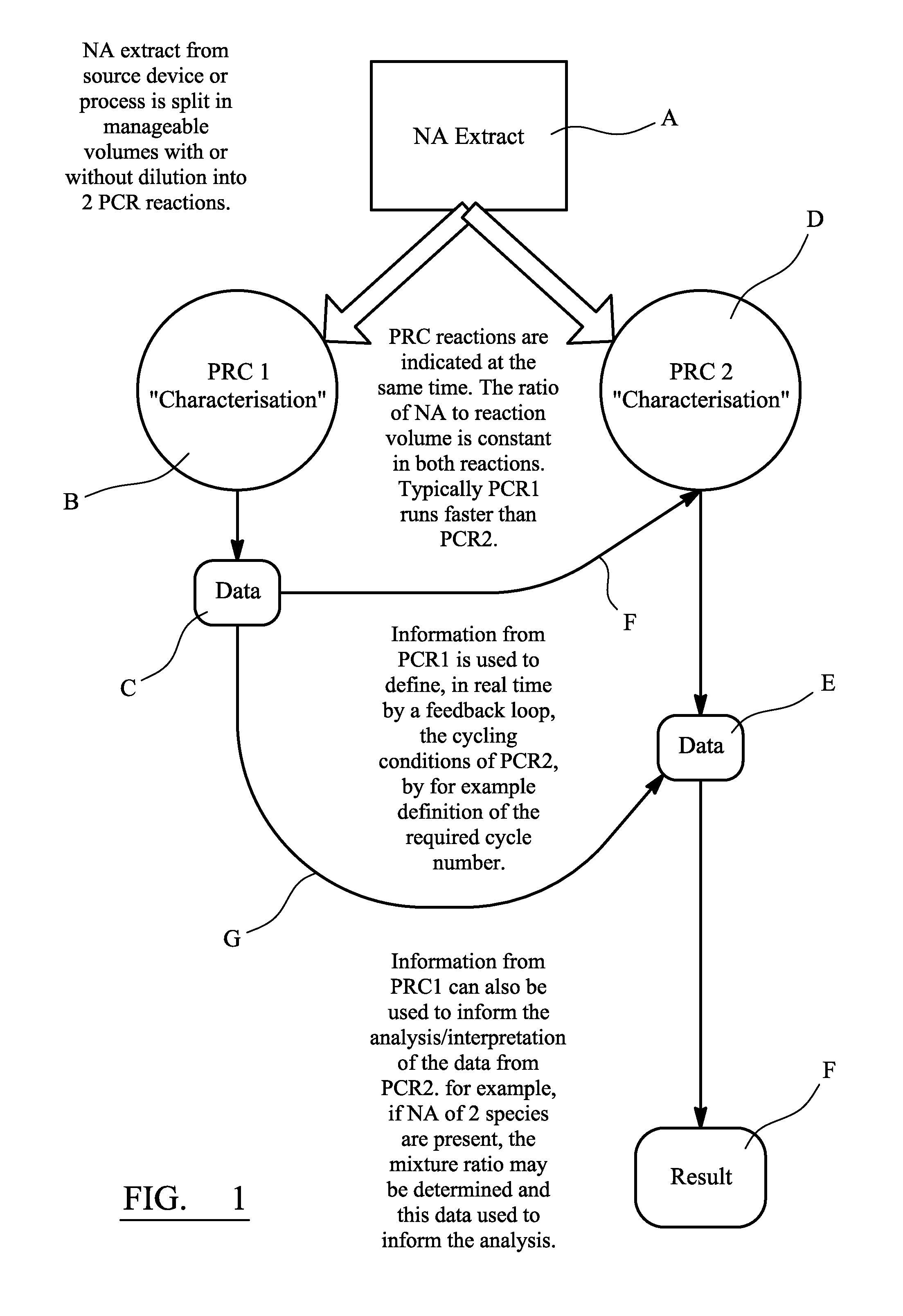

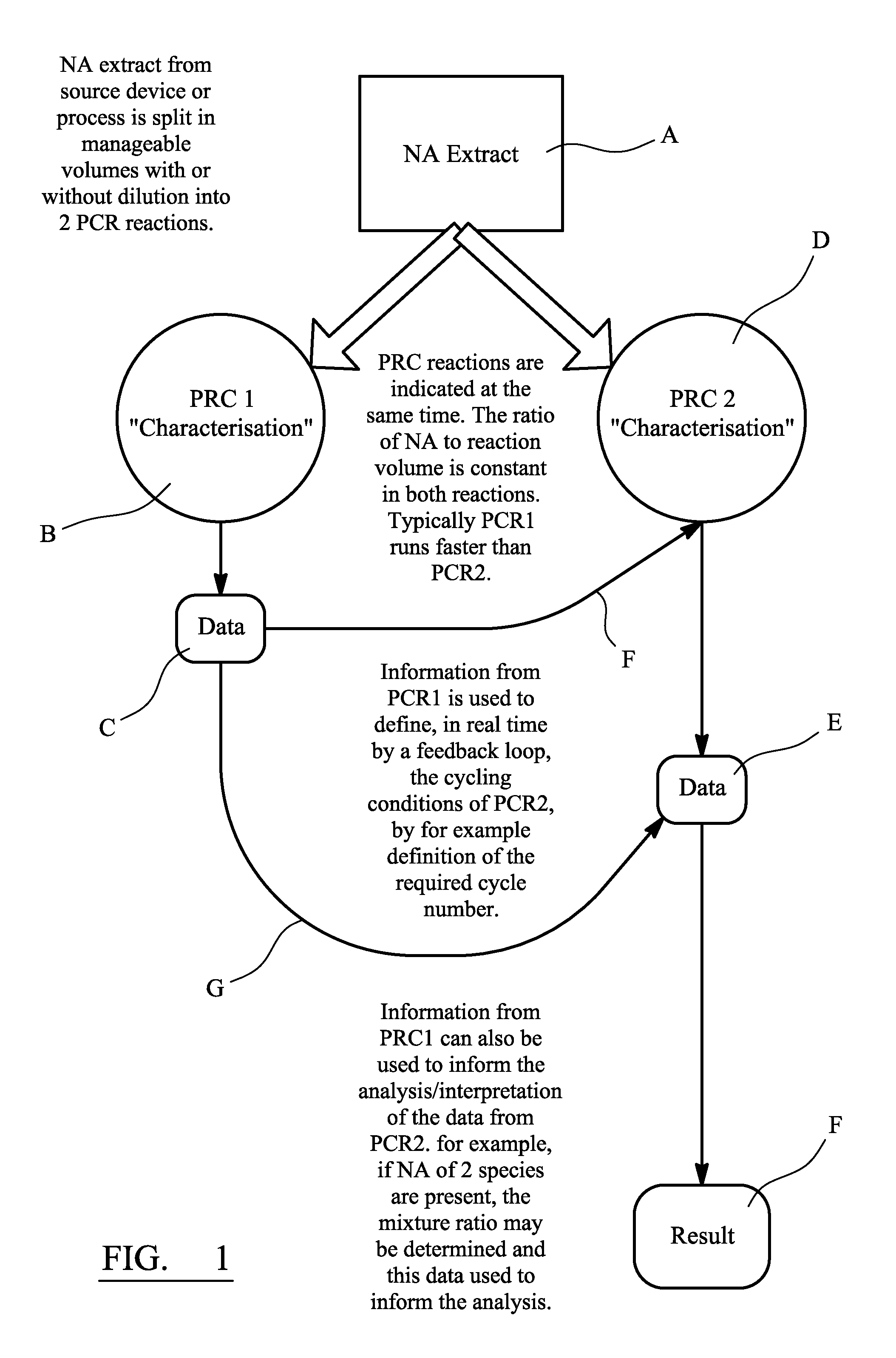

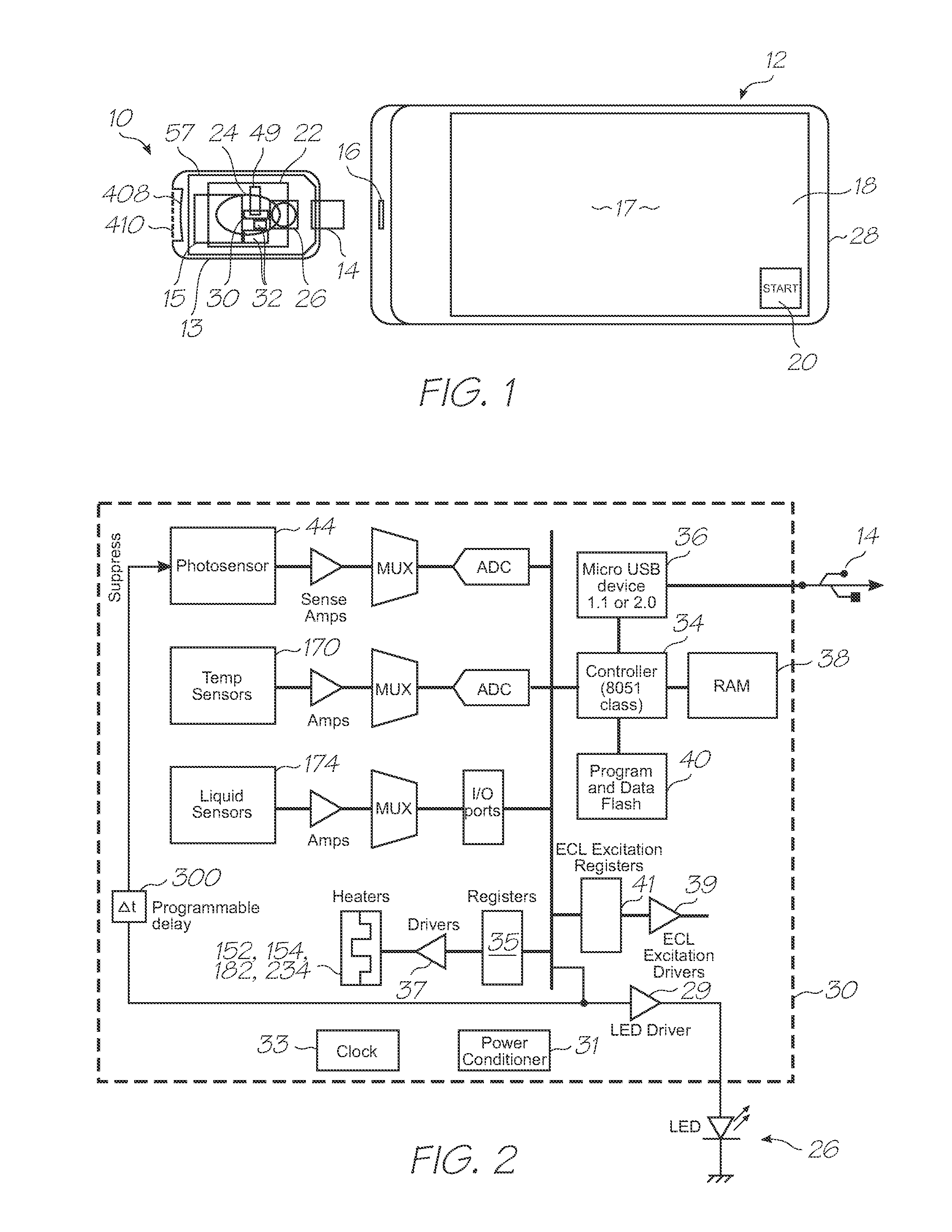

Method of nucleic acids analysis by real-time polymerase chain reaction and device for performing the same

ActiveUS9631229B2Low costShorten the timeBioreactor/fermenter combinationsBiological substance pretreatmentsChemical physicsCost effectiveness

With respect to molecular biology, medicine, and biotechnology, provided is a method related to the performance of Polymerase Chain Reaction. The method includes using the device for identification of nucleic acids containing a microchip with at least one reaction zone on its surface. The microchip contains a heat-conducting substrate made of aluminum while each reaction zone is separated from the heat-conducting substrate by a layer of the passivating material covalently bound to the surface of the heat-conducting substrate while over the layer of the passivating material one or several dried components of the polymerase chain reaction is placed. In this method the ratio of the aggregate thermal mass of the microchip to thermal conductance of the microchip substrate does not exceeding 0.04 s. The technical result is reduced duration of the analysis, higher reliability, accuracy, efficiency and cost-effectiveness of the analysis.

Owner:LUMEX INSTR

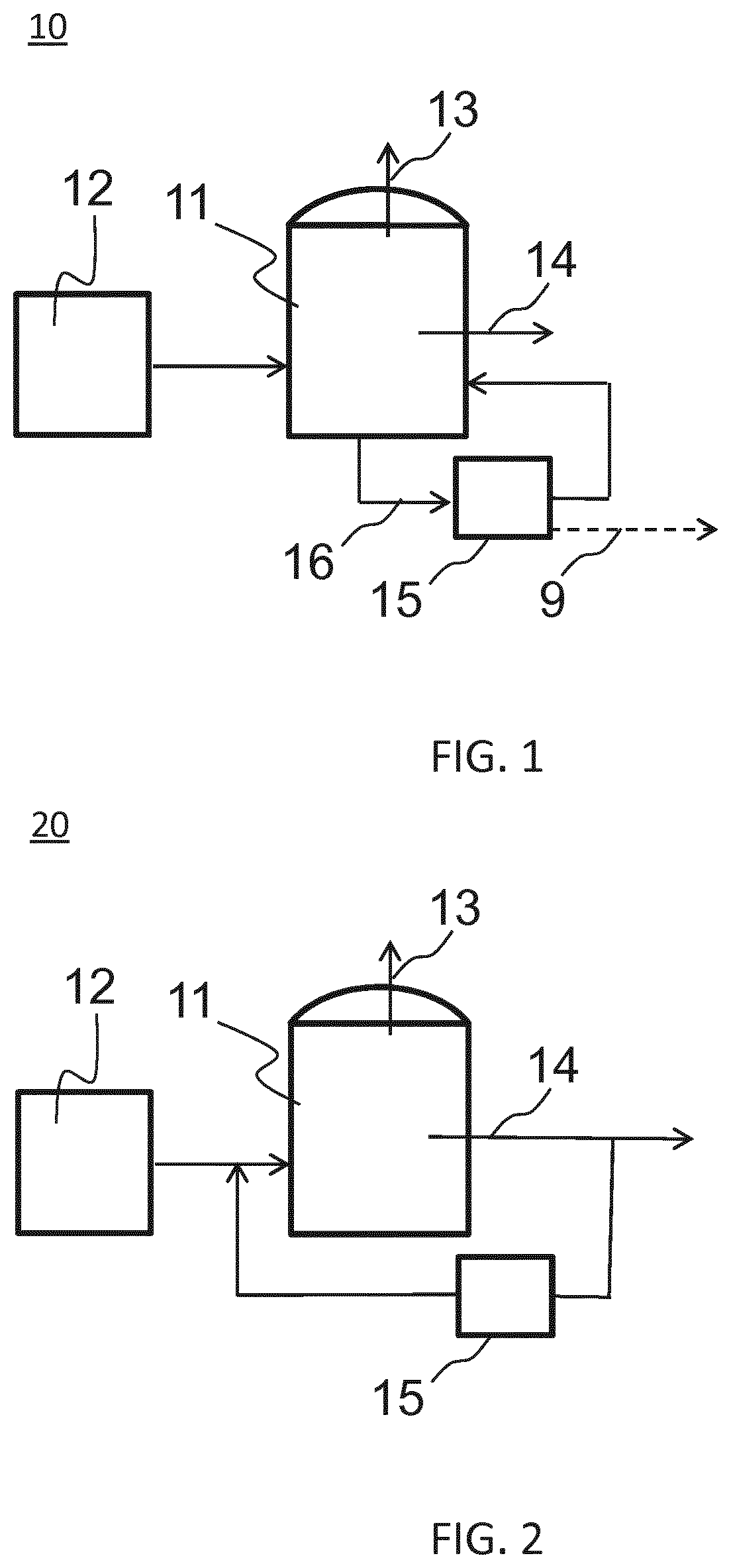

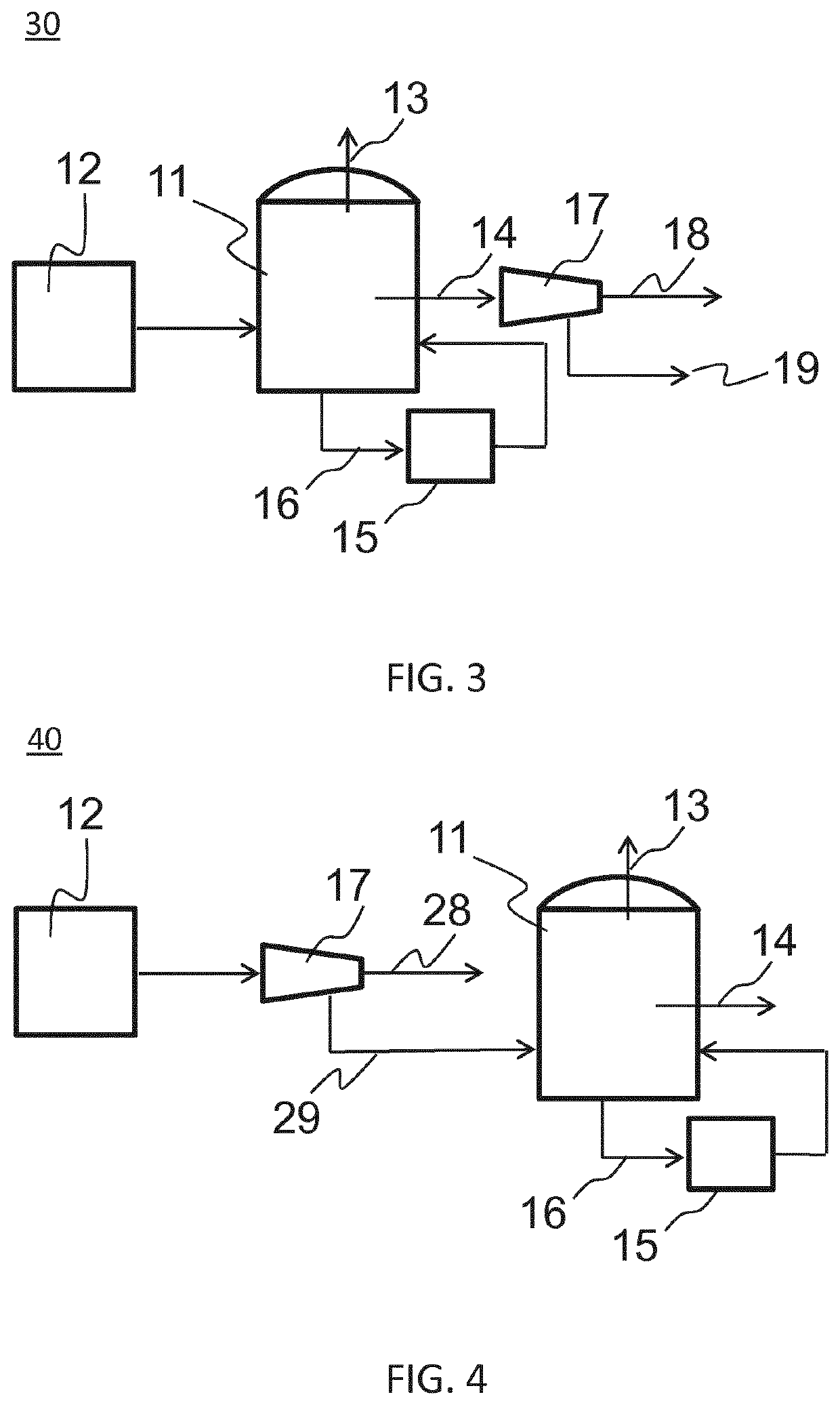

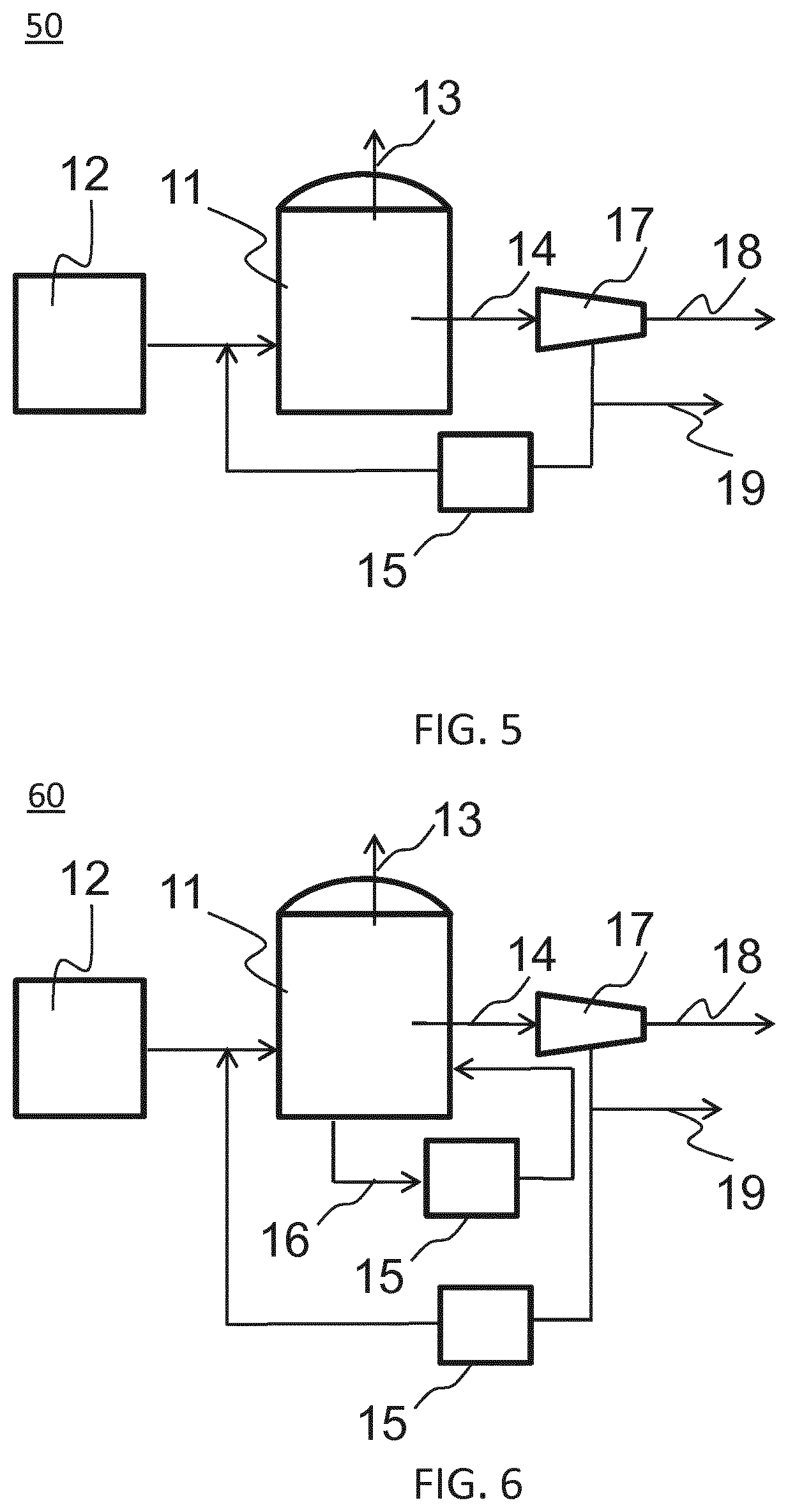

Apparatus and method for refractory organics conversion into biogas

ActiveUS20200165553A1Increase biogas productionLower requirementBioreactor/fermenter combinationsBiological substance pretreatmentsPhysical chemistryDigestate

An apparatus for refractory organics conversion into biogas includes an anaerobic digester configured to be fed with organic material comprising refractory organics and to generate biogas and a digestate comprising at least a part of the refractory organics, wherein the apparatus comprises a device for a controlled partial oxidation of the refractory organics comprising an inlet configured to be fed with refractory organics and means configured to control the residence time of the refractory organics within the device for a controlled partial oxidation, so as to partially degrade refractory organics. A method for refractory organics conversion into biogas carried out using such an apparatus is also provided.

Owner:SUEZ INT

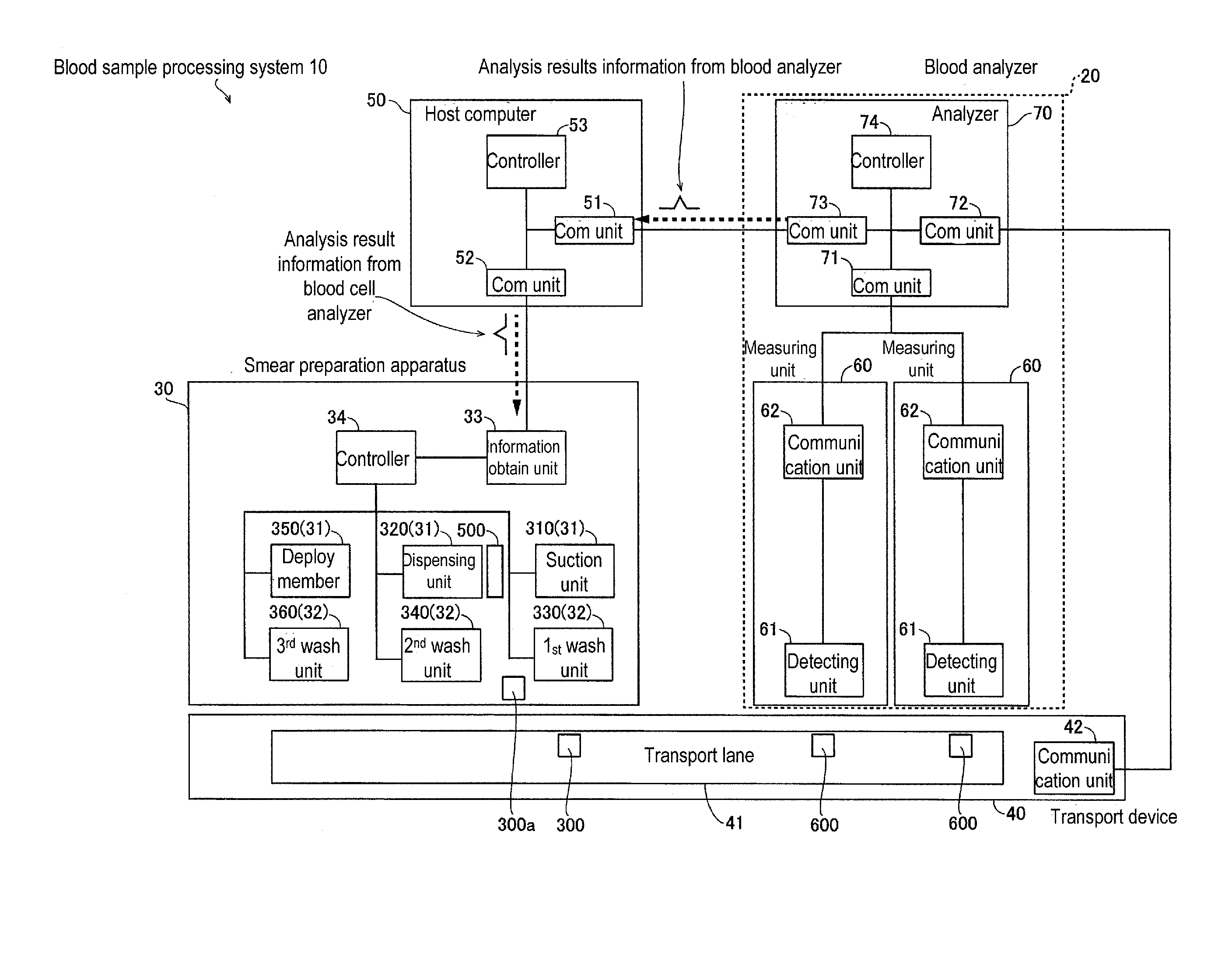

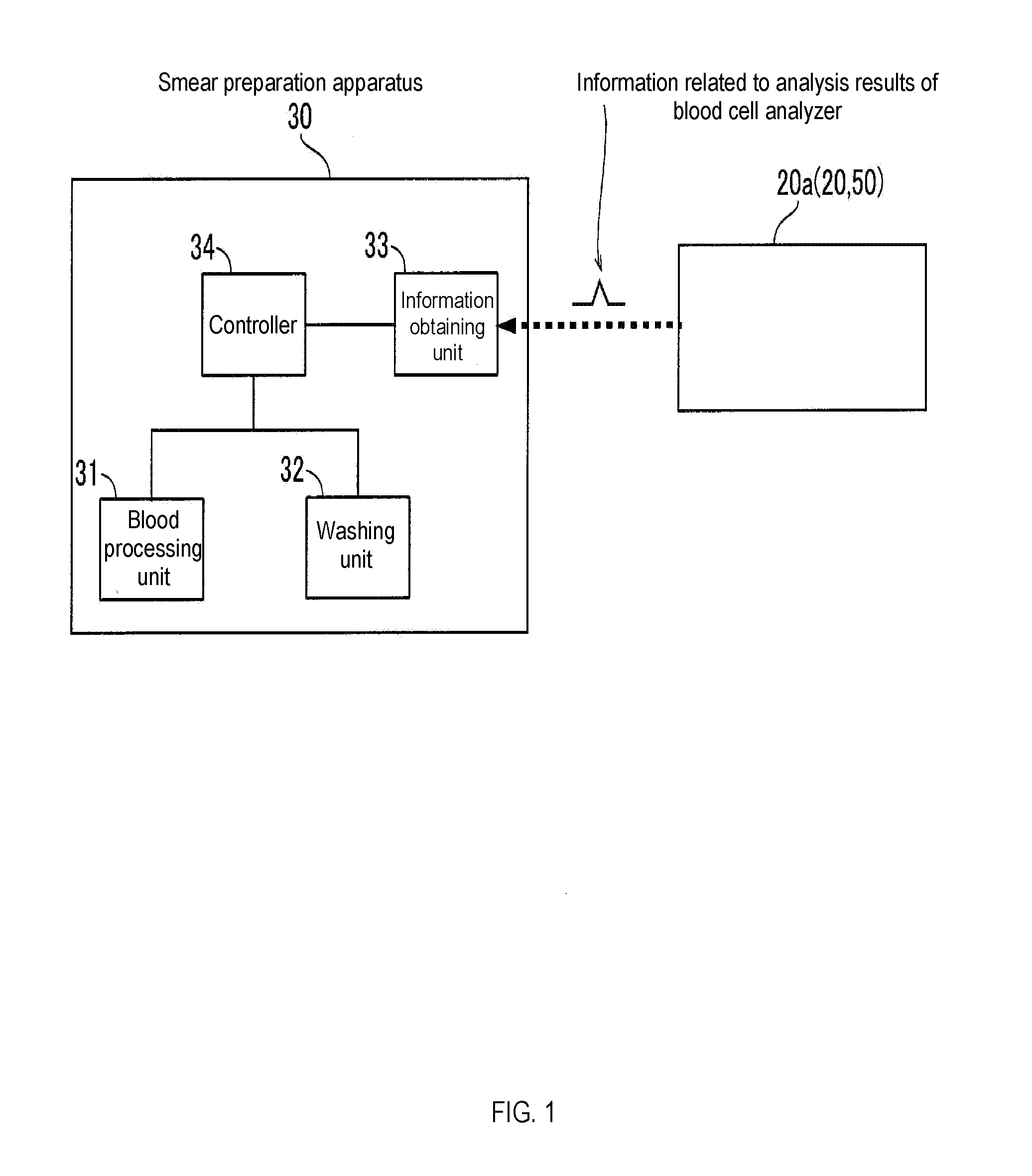

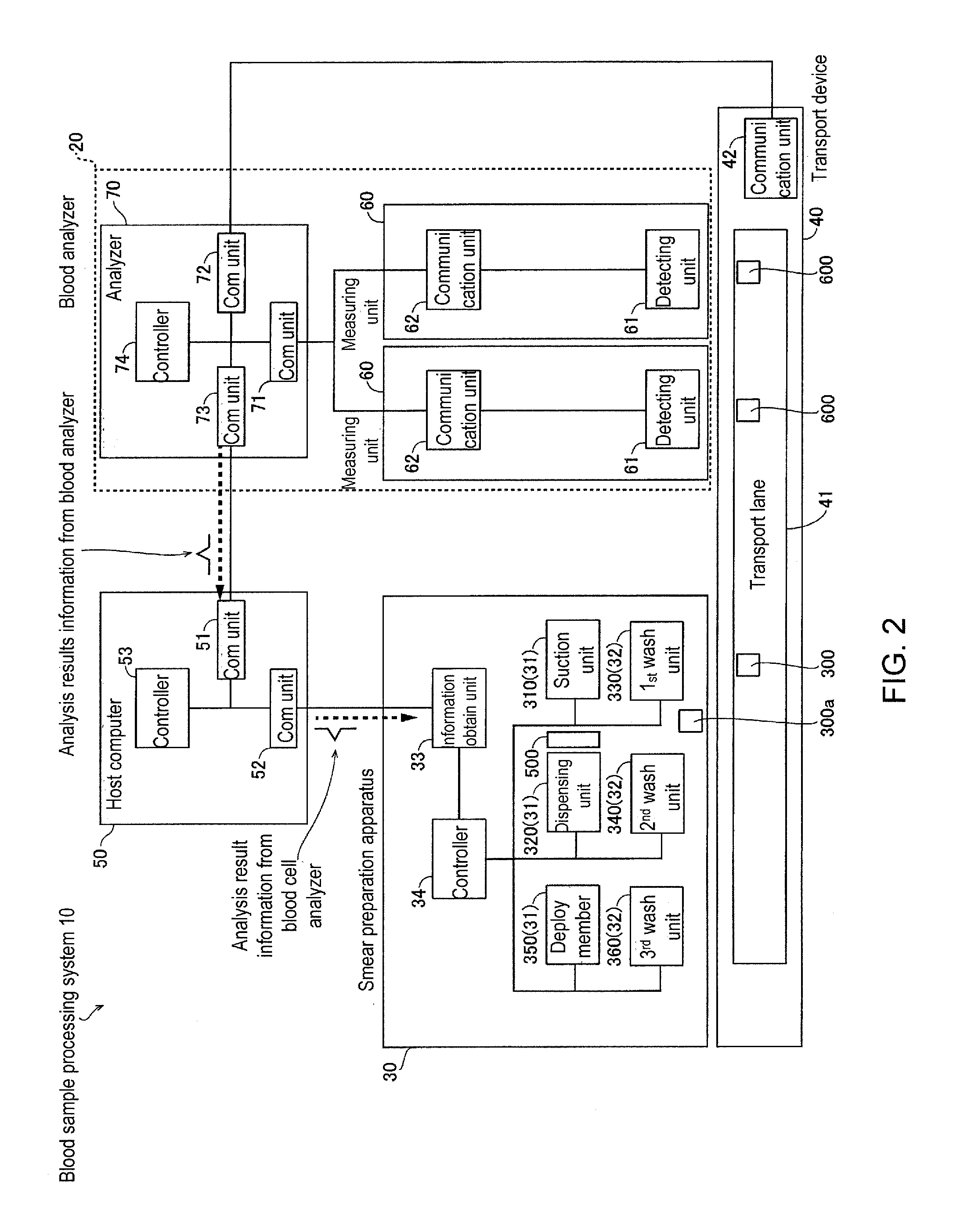

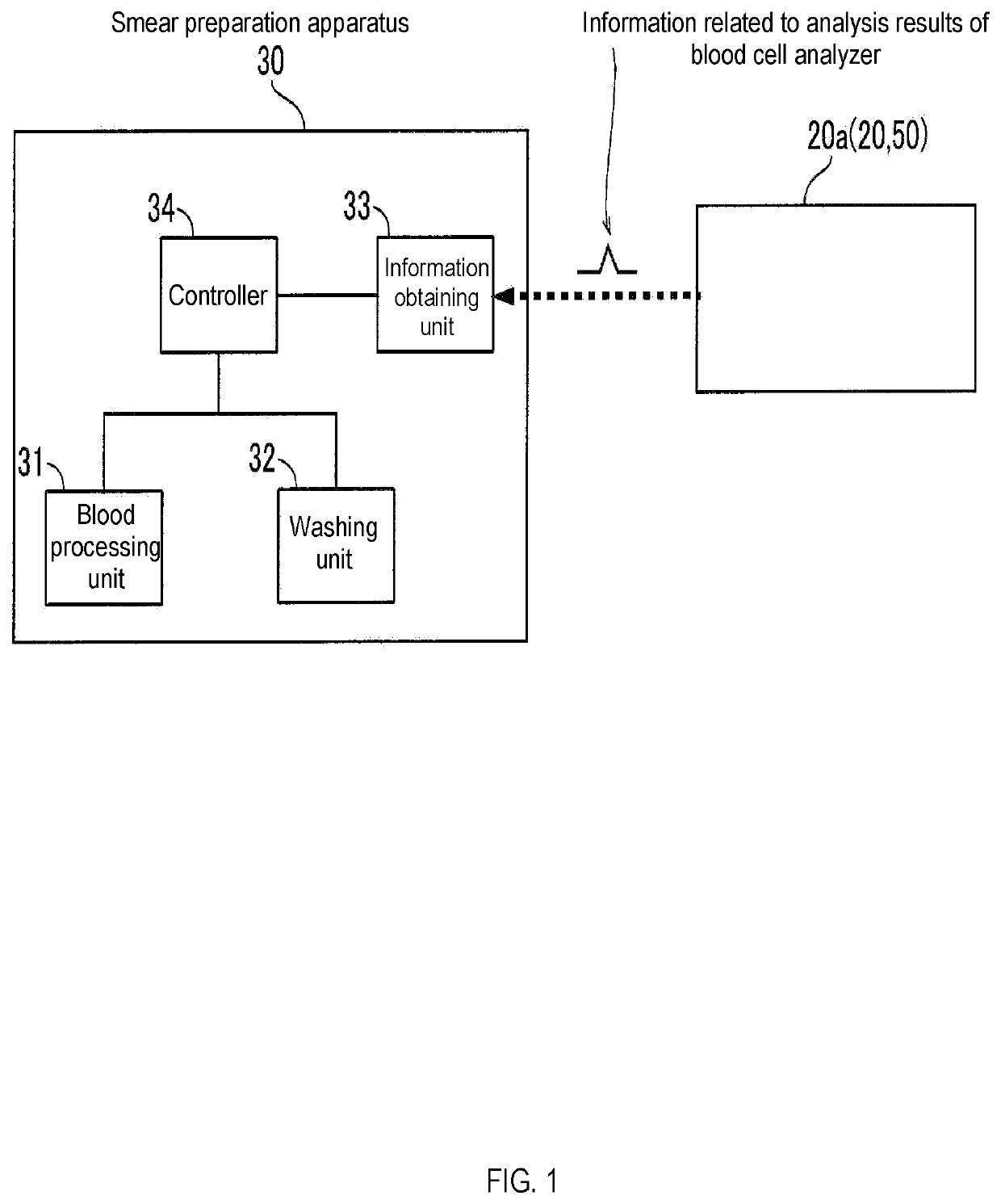

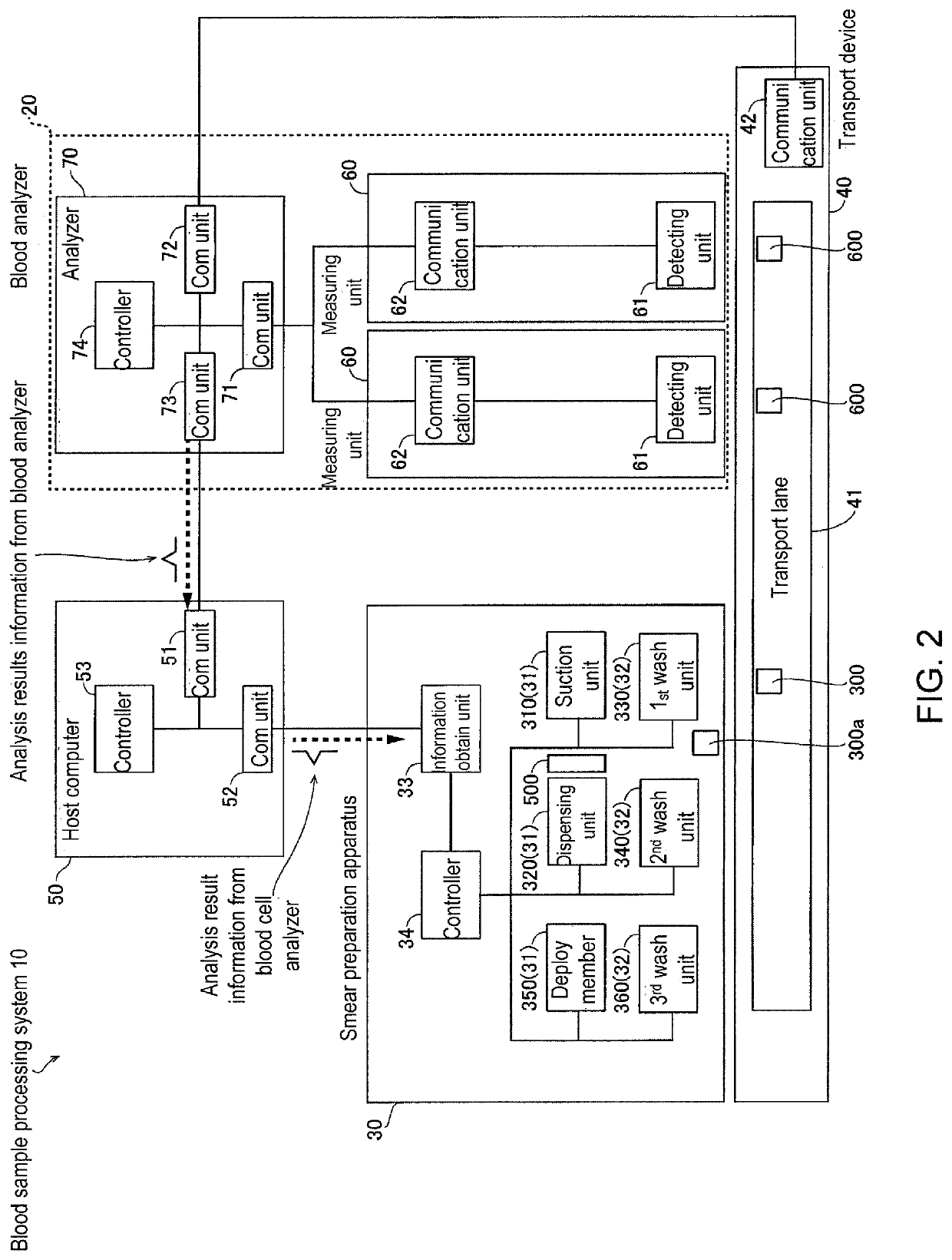

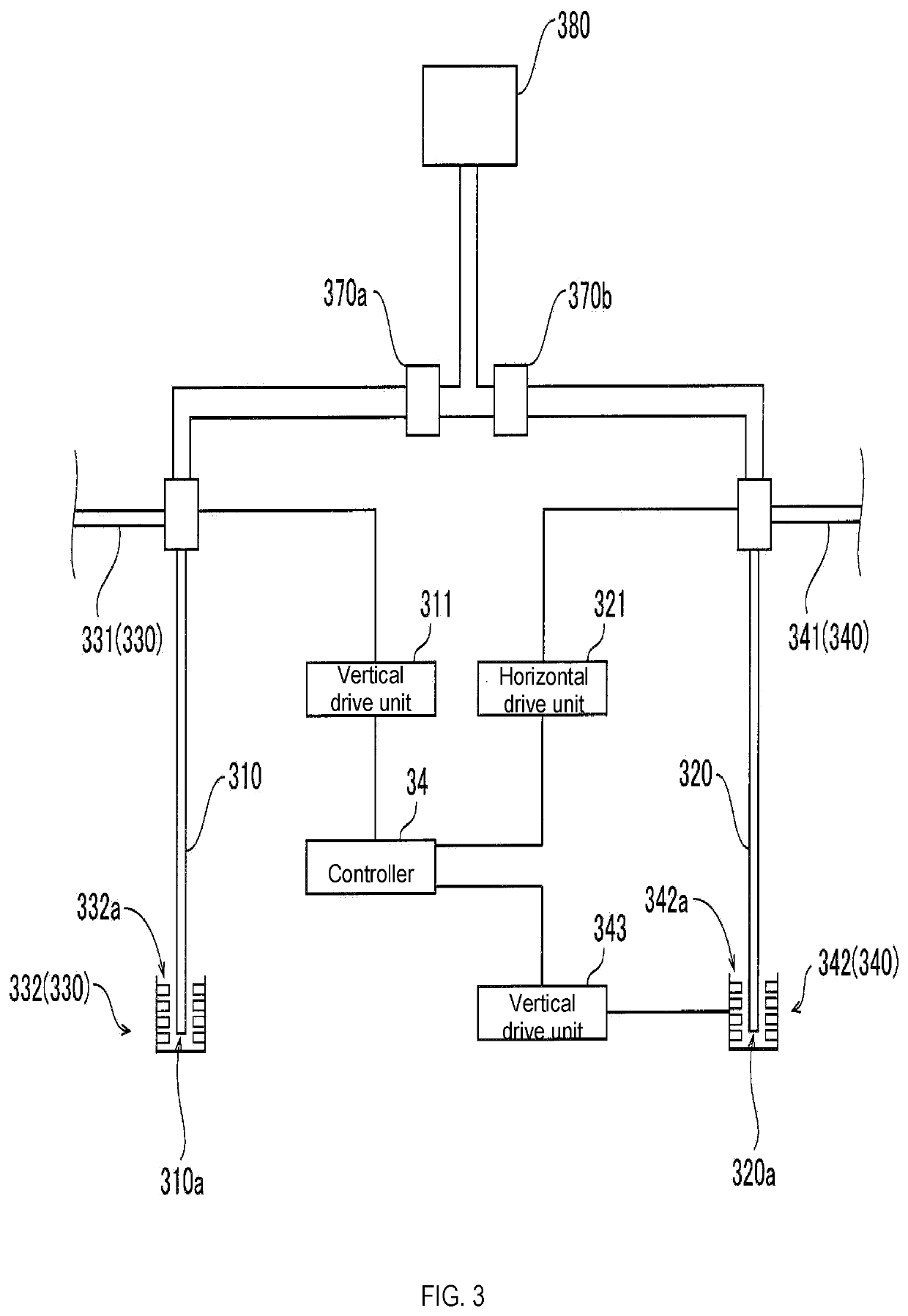

Smear preparation apparatus, blood sample processing system, and method of washing blood processing unit of the smear preparation apparatus

ActiveUS20170003204A1Reduce the impactEasy to processPreparing sample for investigationBiological testingBlood processingAbnormal blood cells

A smear preparation apparatus comprises a blood processing unit, a washing unit, a controller, an information obtaining unit. The controller changes the washing condition for washing after processing a blood sample to a second washing condition which is stronger than the first washing condition when abnormal blood cells occur in the blood sample.

Owner:SYSMEX CORP

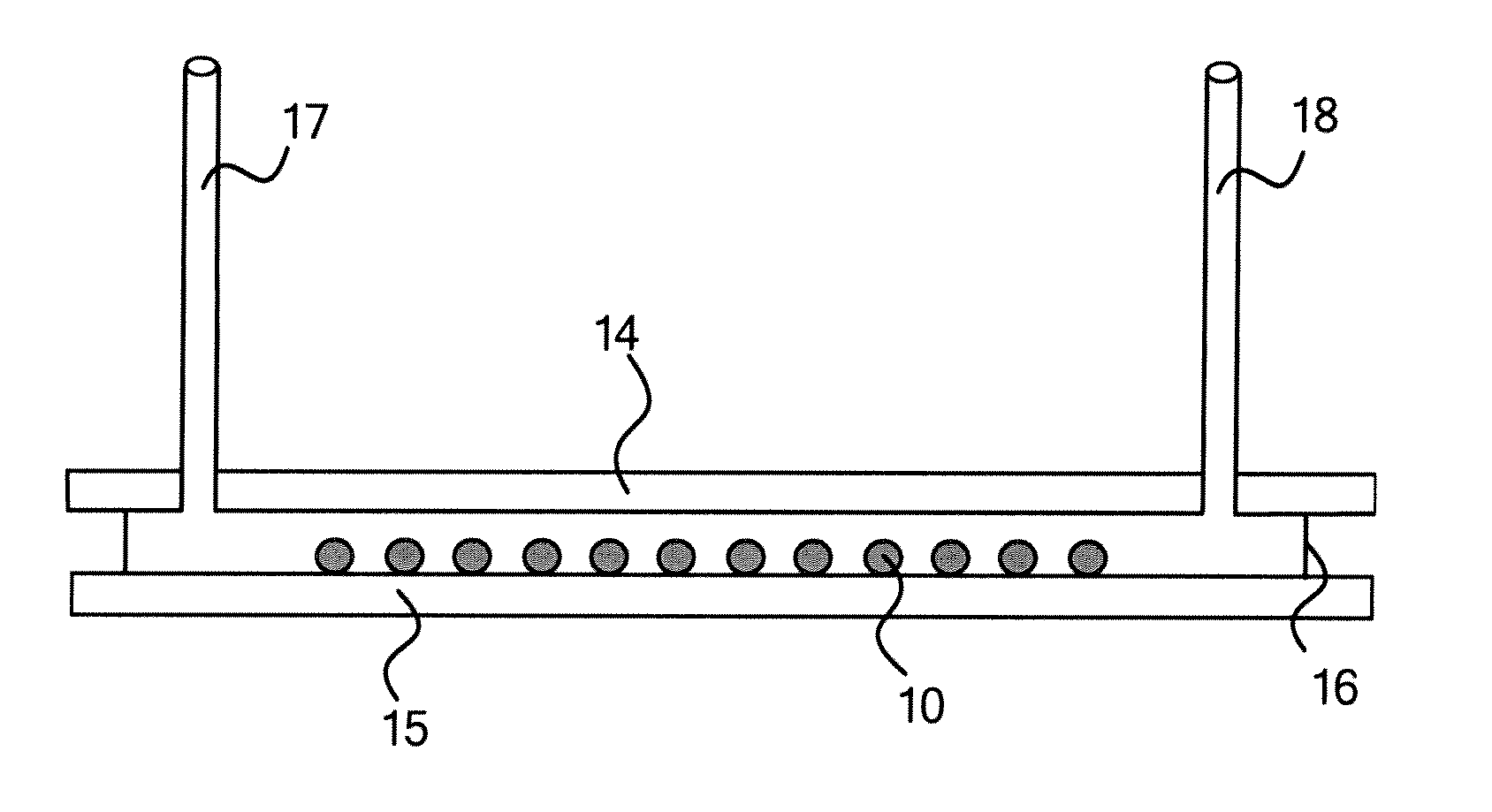

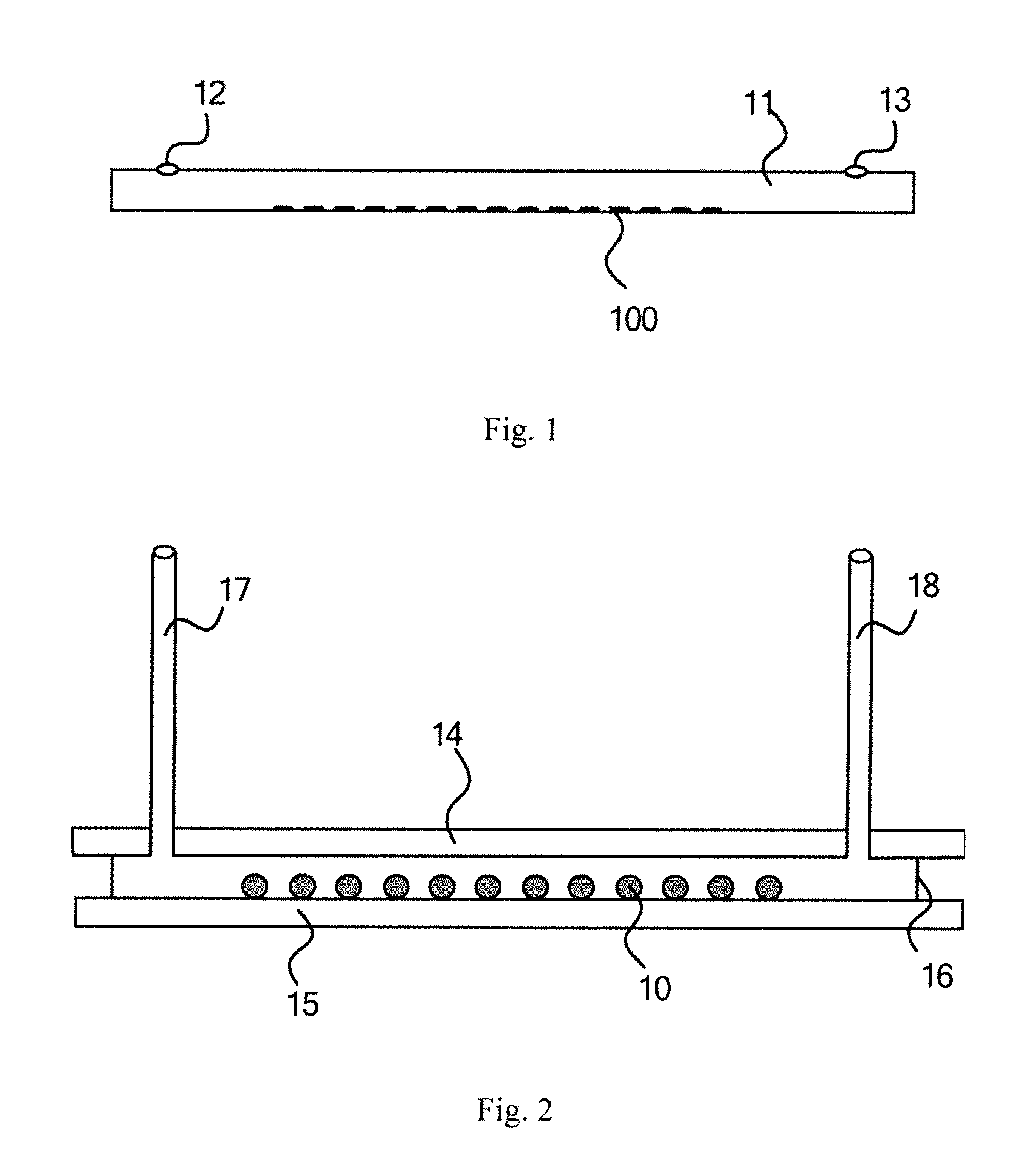

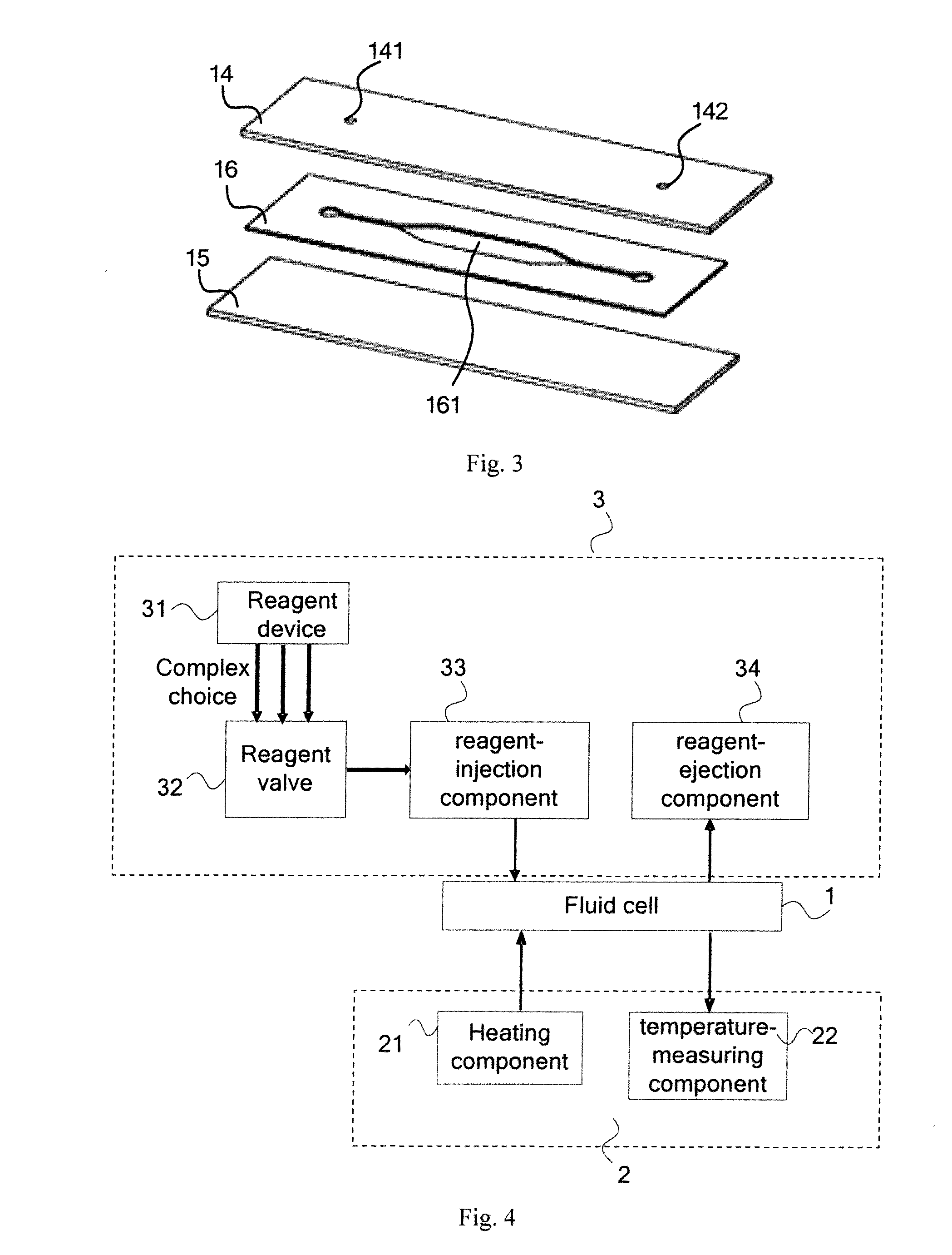

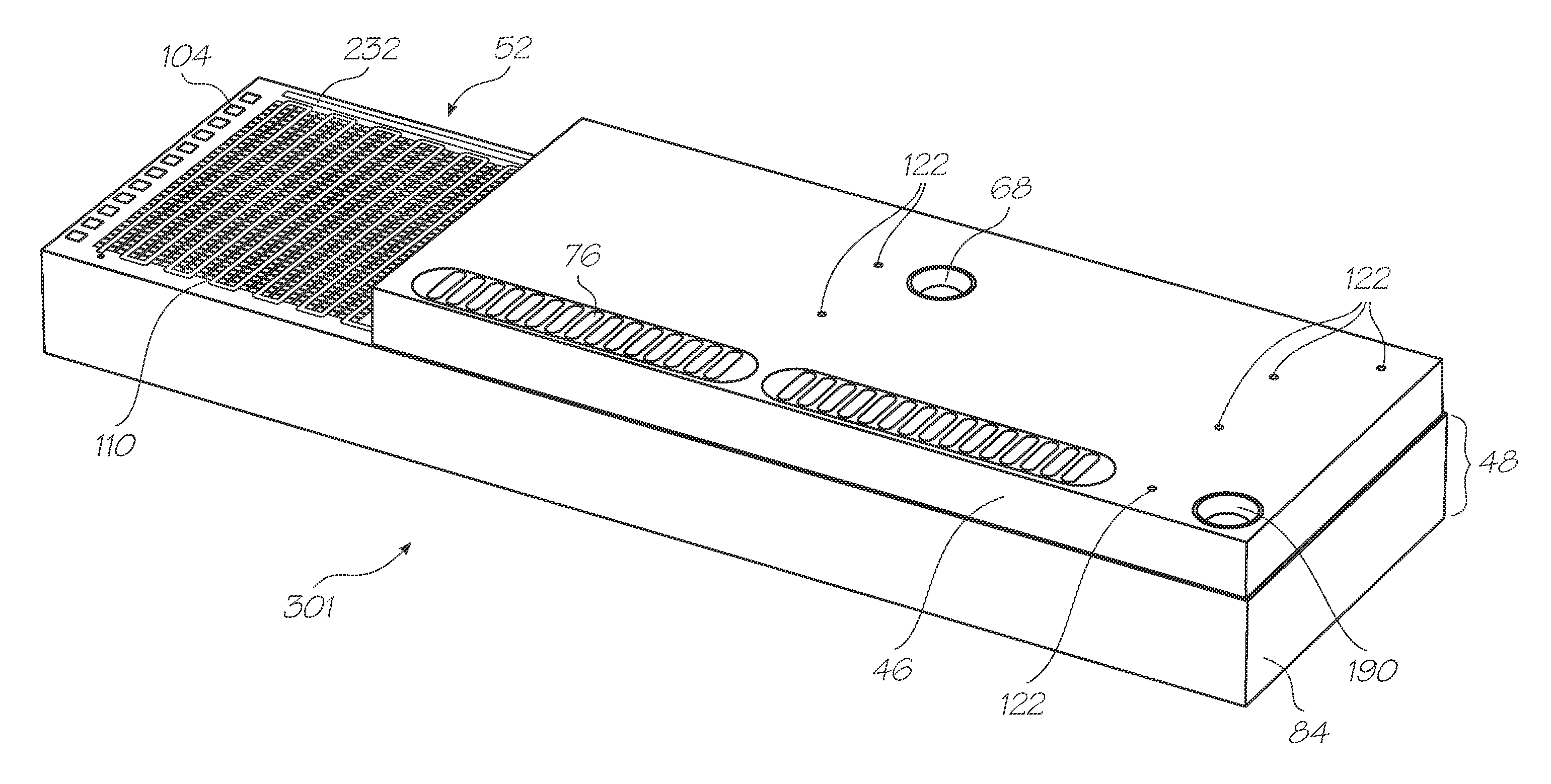

Fluid cell and gene sequencing reaction platform and gene sequencing system

InactiveUS20110124094A1Smooth connectionDelayed reaction timeBioreactor/fermenter combinationsHeating or cooling apparatusDiffusion barrierGene

In the invention, a fluid cell, used for sequencing reaction between DNA fragments and reagents, comprises: a reaction chamber, one inner side of which is fixed with multiple DNA fragments; a reagent inlet and a reagent outlet, which are separately located at each end of the other inner side of the reaction chamber and used for reagents flowing into and out from the reaction chamber. Multiple DNA fragments are fixed on the reaction chamber with the small capacity as short tag arrays in sequence and make the reaction go on at the condition of the reagents without diffusion barriers, which improves the contacts of reagents and DNA fragments so as to shorten the reaction time. At the same time, the demands to the concentration and dosage of reagents are low, which reduces the consumption of reagents. As the result, the sequencing cost cut down. Multiple DNA fragments are fixed on the fluid cell at the same time, which provides a way for parallel reaction of various fragments. The automatic high-through sequencing and fast sequencing reactions are achieved in the invention.

Owner:SHENGZHEN CHINA GENE TECH COMPANY

Analysis

InactiveUS20130137103A1No added complexitySimple processBioreactor/fermenter combinationsBiological substance pretreatmentsComputer science

Owner:WHITESPACE ENTERPRISE

Test module with microfluidic device having loc and dialysis device for separating pathogens from other constituents in a biological sample

InactiveUS20110312627A1Fast detection timeLow costOptical radiation measurementRadiation measurementMedicineLab-on-a-chip

A test module for concentrating pathogens in a biological sample, the test module having an outer casing with a receptacle for receiving the sample, a dialysis device in fluid communication with the receptacle and configured to separate the pathogens from other constituents in the sample, and, a lab-on-a-chip (LOC) device being in fluid communication with the dialysis device and configured to analyze the pathogens.

Owner:GENEASYS

Sampling membrane, sampler and application method for enriching heavy metals in ambient air

InactiveCN103674624BGas extraction resistance is smallReduce weightWithdrawing sample devicesFiberDesorption

The invention discloses a sampling membrane and a sampler capable of enriching heavy metals in ambient air and an application method of the sampler. The sampling membrane comprises a nanometer fiber membrane and an air-permeable supporting padding arranged below the nanometer fiber membrane. The sampler comprises the sampling membrane and a sampling clamp; the sampling clamp is composed of an upper cone and a lower cylinder, wherein the upper surface of the cone is horizontal, the cylinder is composed of an upper cylinder and a rotary lower cylinder, the side surfaces of the upper cylinder and the lower cylinder are provided with uniformly distributed vertical ridges, the vertical ridges on the upper cylinder and the lower cylinder are aligned by rotating the lower cylinder, so fixation of the sampling membrane on the horizontal surface of the sampling clamp is realized. After heavy metals in air are acquired by using the sampler, a filter membrane is taken out and put into a centrifuge tube filled with a buffer solution, a solution is used for desorption of the heavy metals on the filter membrane, and after desorption, the solution is determined. According to the invention, detection sensitivity can be substantially improved, pre-treatment of a sample is easy and feasible, and nanometer fiber filter membranes with different functions are used for different detection objects, thereby improving absorption and acquisition efficiency.

Owner:SOUTHEAST UNIV +1

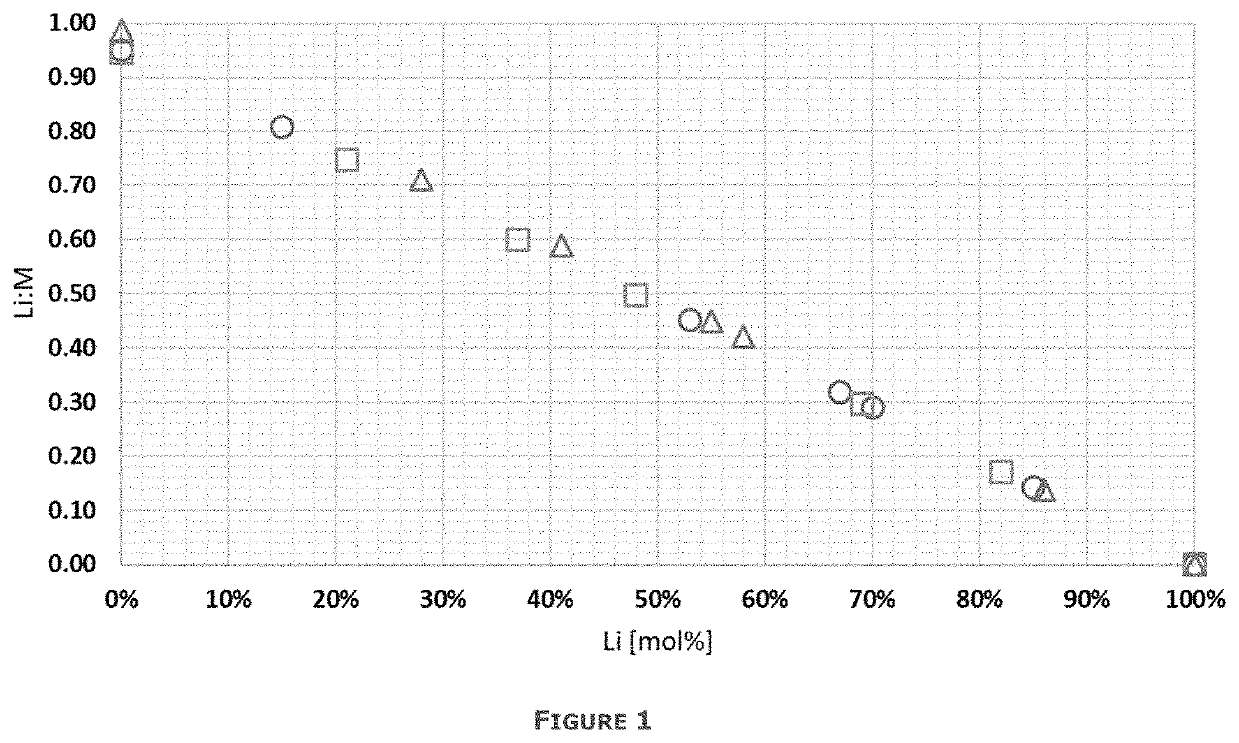

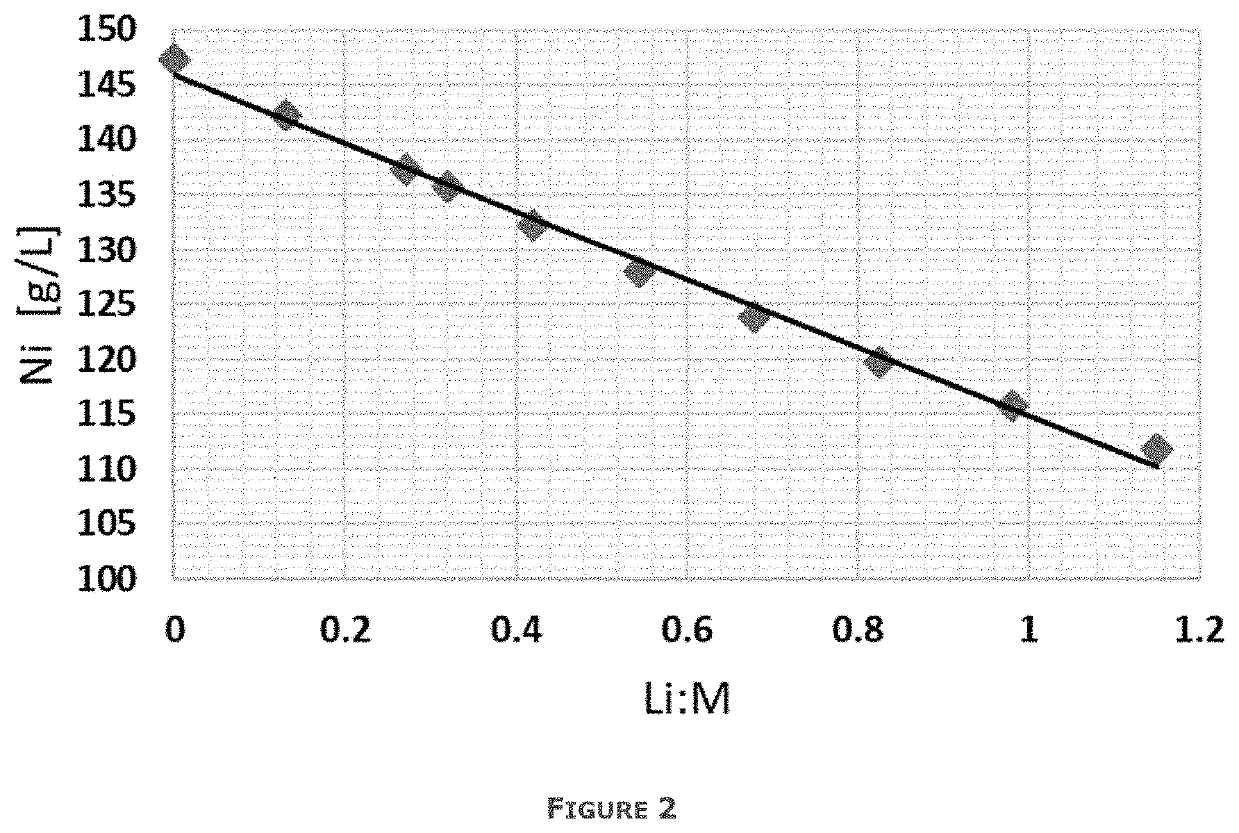

Process for the preparation of battery precursors

PendingUS20220223933A1Easy to handleReduce reagent consumptionReclaiming serviceable partsWaste accumulators reclaimingPhysical chemistryProcess engineering

The invention concerns a process for the recovery of metals such as Ni and Co from a Li-containing starting material.In particular, this process concerns the recovery of metals M from a Li-containing starting material, wherein M comprises Ni and Co, comprising the steps of:Step 1: Providing said starting material, comprising Li-ion batteries or their derived products;Step 2: Removing Li in an amount of more than the maximum of (1) 30% of the Li present in said starting material, and (2) a percentage of the Li present in said starting material determined to obtain a Li:M ratio of less than 0.70 in a subsequent acidic leaching step;Step 3: Subsequent leaching using relative amounts of Li-depleted product and a mineral acid, thereby obtaining a Ni- and Co-bearing solution; and,Step 4: Crystallization of Ni, Co, and optionally Mn.Due to the lower reagent consumption and higher Ni and / or Co concentration during hydrometallurgical processing, the invention is an efficient and economic process for the production of crystals suitable for battery material production.

Owner:UMICORE AG & CO KG

Photometric instrument

InactiveUS8004673B2Minimal timeReduce reagent consumptionRadiation pyrometrySpectrum investigationParticulatesPhotoluminescence

Owner:HITACHI HIGH-TECH CORP

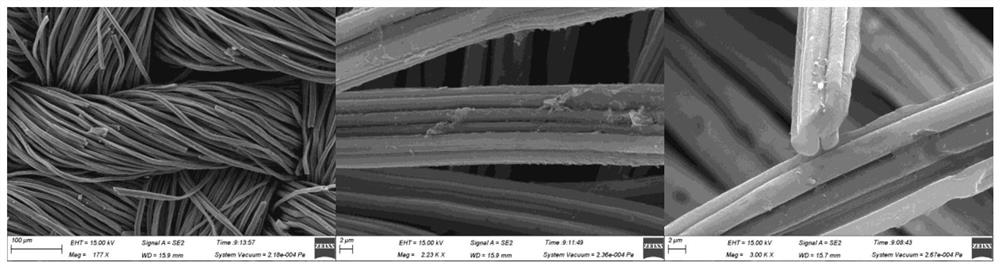

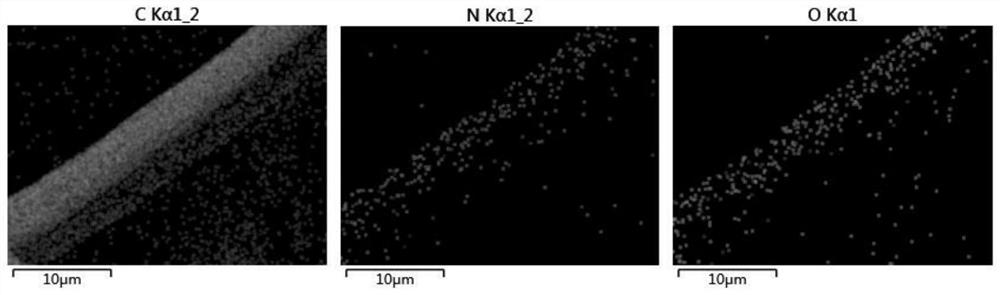

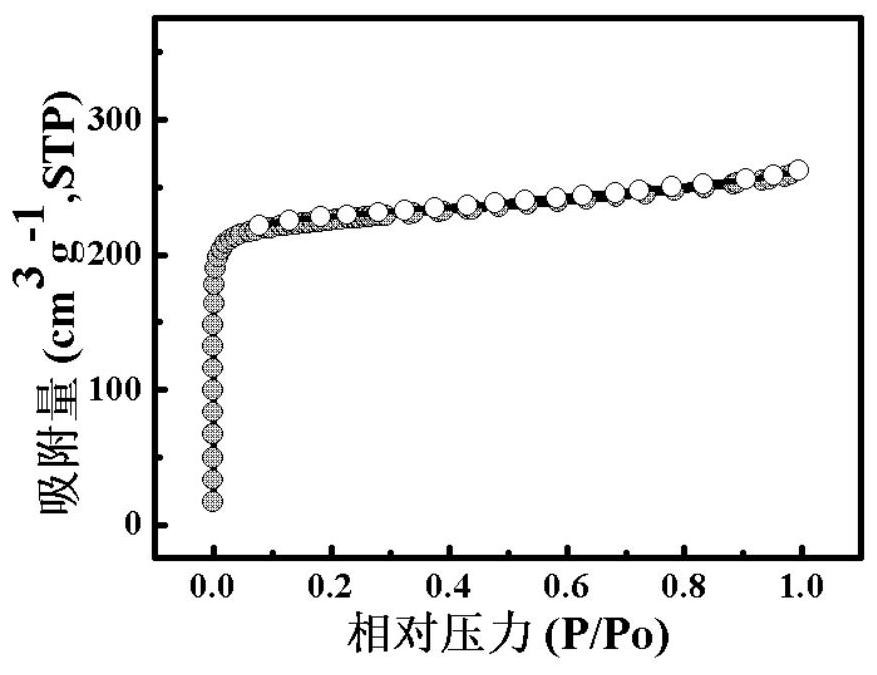

Viscose-based nitrogen-containing active carbon fiber material as well as preparation method and application thereof

ActiveCN113060726AReduce reagent consumptionLarge specific surface areaProductsMethane captureActive carbonViscose

The invention belongs to the technical field of preparation and application of active carbon fiber materials, and particularly relates to a viscose-based nitrogen-containing active carbon fiber material as well as a preparation method and application thereof. The mass content of nitrogen in the material is 4.27-7.43%, the specific surface area is 609-1159 cm < 2 > / g, and the total pore volume is 0.31-0.54 cm < 3 > / g. The viscose-based nitrogen-containing active carbon fiber material is large in specific surface area and high in microporosity, the used raw materials are easy to obtain, economical and environmentally friendly, carbonization-activation is completed in one step in preparation of the viscose-based nitrogen-containing active carbon fiber material, operation is simple, and time consumption and energy consumption are reduced. The viscose-based nitrogen-containing active carbon fiber material has good adsorbability to carbon dioxide, has excellent CO2 / CH4 selectivity, and has a wide application prospect in the field of gas adsorption and separation.

Owner:HENAN POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com