Sampling membrane, sampler and application method for enriching heavy metals in ambient air

A technology of ambient air and application methods, applied in the direction of sampling devices, etc., can solve the problems of difficult elution and extraction of the analyte, large gas extraction resistance, and low mechanical strength, so as to shorten sampling and processing time, small gas extraction resistance, The effect of low blank value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A kind of preparation method of the sampling film of enriching the heavy metal in ambient air, comprises the following steps:

[0029] (1) Dissolve high molecular polymer (at least one of polyphenylene sulfide, cellulose acetate, polystyrene, polycaprolactam, acrylic resin and polyacrylonitrile) in a suitable solvent (N, N-dimethyl At least one of base formamide, tetrahydrofuran, ethanol, acetone, formic acid, water, halogenated hydrocarbons and aromatic hydrocarbons), stirred to form a spinning solution, and then added to the spinning solution relative to the polymer mass 3 ~8% complexing agent (o-phenanthroline, zinc reagent, 8-hydroxyquinoline, dithizone, 1-(2-pyridylazo)-2-naphthol, xylenol orange or copper reagent at least one) as a functional modifier, and adjust the pH value of the spinning solution;

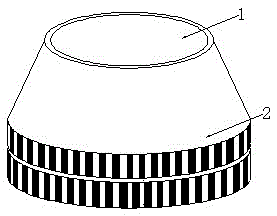

[0030] (2) Using electrospinning technology to make the spinning solution prepared in step (1) into a nanofiber membrane material, then cut the nanofiber membrane...

Embodiment 1

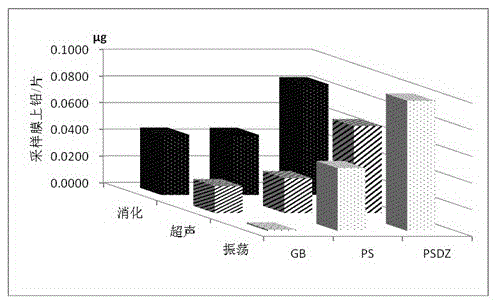

[0034]Preparation of dithizone functionalized polystyrene nanofiber (DZ-PS) filter membrane: take 10% (w / v) PS (polystyrene) dissolved in DMF (N, N-dimethylformamide) and THF ( Tetrahydrofuran) (4:6) mixed solution, after the PS is completely dissolved, add 5% (w / w, relative to the mass of PS) dithizone, and continue stirring with a magnetic stirrer for more than 10 hours. Put it into a glass syringe (soak in 1+9 nitric acid overnight, wash and dry in deionized water), install the needle, install aluminum foil of appropriate size on the receiving plate, and cover the aluminum foil with gauze (soak in 1+9 nitric acid overnight, use deionized water washing and drying). Set the voltage to 17KV, the flow rate to 1.0ml / h, adjust the distance between the receiving plate and the needle to about 25cm, according to about 1ml / 40cm 2 (Amount of spinning solution / receiving area) for electrospinning. The spun nanofibers were cut into circular sheets of appropriate size, lined with a filt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com