Antifouling and antibacterial shoe upper material and preparation method thereof

A technology for shoe uppers and outer layer materials, which is applied in shoe uppers, chemical instruments and methods, anti-coloring pollution/anti-fouling fibers, etc., and can solve the problems of difficult cleaning and poor anti-fouling performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

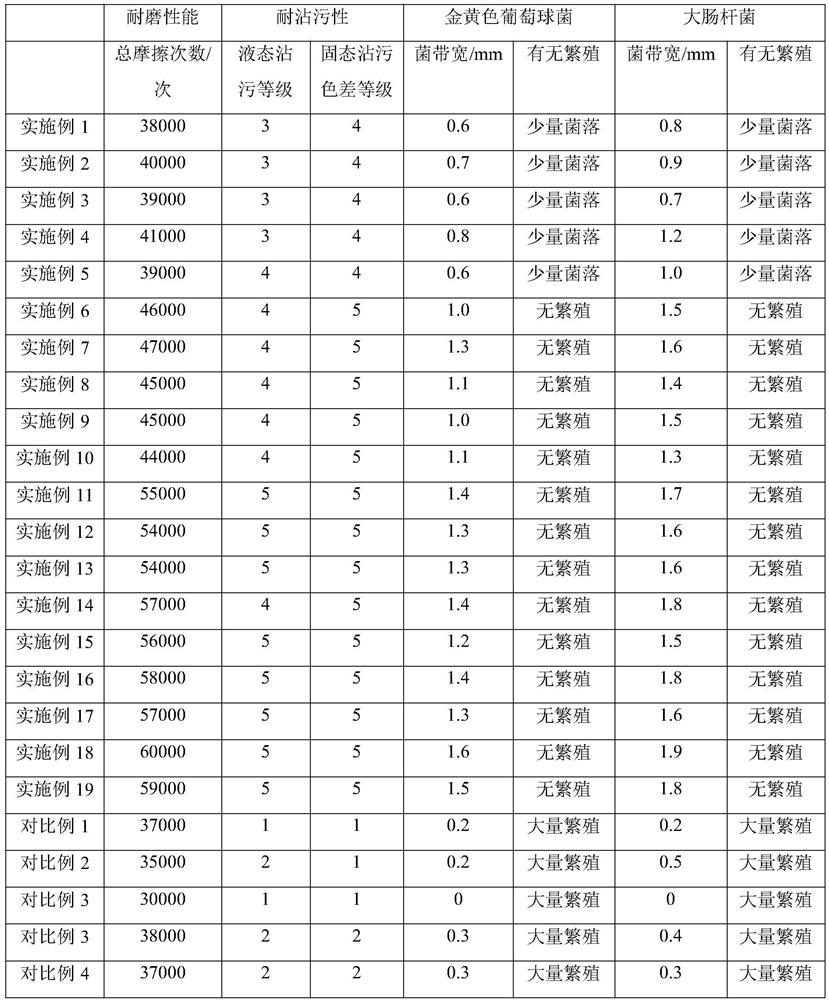

Examples

Embodiment 1

[0047] A method for preparing an antifouling and antibacterial shoe upper material, comprising the following steps:

[0048] Preparation of electrospun fibers: After melting 20kg of terephthalic acid, 35kg of ethylene glycol, and 50kg of polyamide at a temperature of 250°C, the electrospun fibers were prepared by electrospinning equipment, and then the electrospun fibers were prepared by textile technology. Silk fibers are woven into fabrics to obtain substrate fabrics;

[0049] Titanium dioxide solution preparation: 0.5kg graphene oxide and 10kg nano-titanium dioxide, 1kg silane coupling agent and 20kg water were prepared into a solution;

[0050]Preparation of the nano-filtration layer: Soak the electrospun fiber into a solution of graphene oxide, nano-titanium dioxide and water, soak for 20 hours, take it out, and then dry it at 60°C for 2 hours to obtain the nano-filtration layer;

[0051] Upper material bonding: The lower surface of polyester fiber and nylon blended fabr...

Embodiment 2

[0053] The difference from Example 1: Preparation of electrospun fibers: After melting 30 kg of terephthalic acid, 30 kg of ethylene glycol, and 60 kg of polyamide at a temperature of 260° C., the electrospun fibers were prepared by electrospinning equipment. Then, the electrospun fiber is spun into a fabric through textile technology to obtain a base material fabric;

[0054] Titanium dioxide solution preparation: 0.8kg graphene oxide, 16kg nanometer titanium dioxide, 1.6kg silane coupling agent and 32kg water were prepared into a solution.

Embodiment 3

[0056] The difference from Example 1: Preparation of electrospun fibers: After melting 35 kg of terephthalic acid, 20 kg of ethylene glycol, and 65 kg of polyamide at a temperature of 270° C., the electrospun fibers were prepared by electrospinning equipment. Then, the electrospun fiber is spun into a fabric through textile technology to obtain a base material fabric;

[0057] Titanium dioxide solution preparation: 1kg graphene oxide, 20kg nanometer titanium dioxide, 2kg silane coupling agent and 40kg water were prepared into a solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com