Preparation method and application of super-long slow-release solid scale inhibitor

A scale inhibitor, slow-release technology, applied in the field of industrial water treatment agents, can solve the problems of non-biodegradable, low coating, low oil recovery efficiency, etc., achieve strong ultraviolet absorption capacity, increase reaction sites, and improve scale inhibition performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

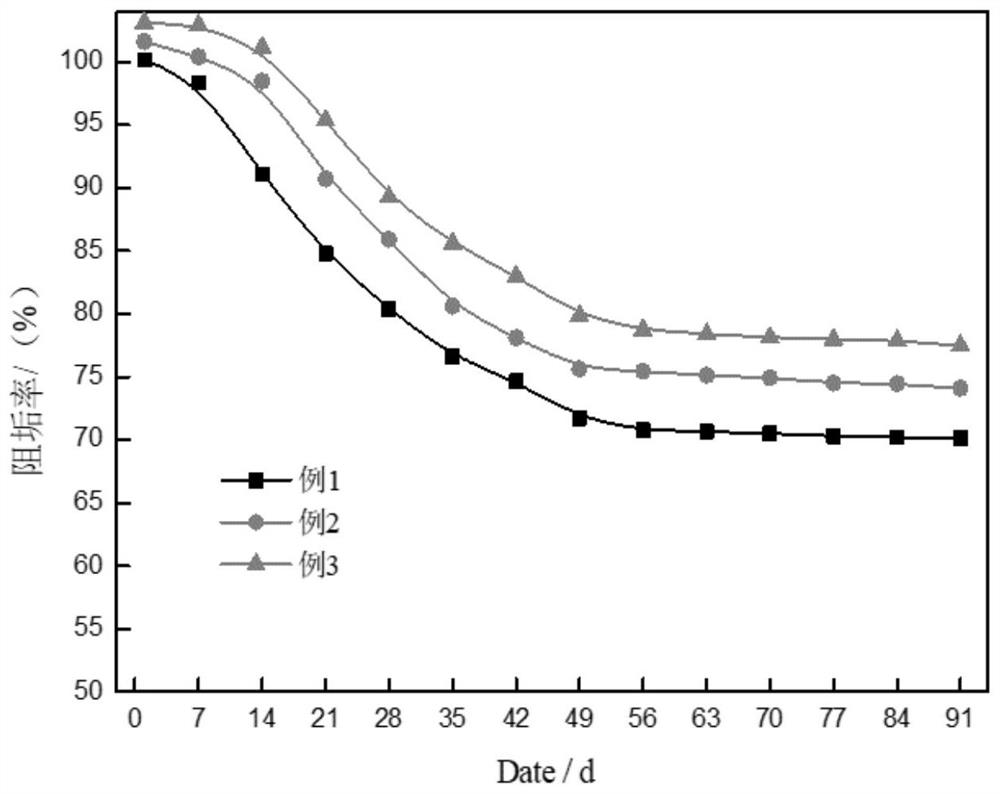

Embodiment 1

[0022] Step 1, the preparation method of the modified polymer scale inhibitor: add 20g of polysuccinimide and 20mL of water into a reactor with a stirring and condensing device, stir for 0.5h, then raise the temperature to 60°C, and then slowly add Drop 30g of sodium p-aminobenzenesulfonate into the suspension, adjust the pH to 9.5-10 with 10% NaOH solution, keep stirring for about 4 hours to obtain an orange oily transparent liquid, and continue to adjust the pH to 6.5 with dilute hydrochloric acid ~7.5; Finally, add about 2 times of absolute ethanol to precipitate a reddish-brown precipitate, and dry the precipitate to obtain a modified polymer scale inhibitor.

[0023] Step 2, the preparation method of activated sodium lignosulfonate is as follows: Add 20 g of sodium lignosulfonate, 0.5 g of ferrous sulfate and 80 g of water in sequence in a stirred reactor, stir and heat up to 60 ° C, dropwise add 5g of hydrogen peroxide, heat-retained and stirred for about 2 hours to obta...

Embodiment 2

[0026] Step 1, the preparation method of the modified polymer scale inhibitor: add 20g of polysuccinimide and 20mL of water into a reactor with a stirring and condensing device, stir for 1.0h, then raise the temperature to 65°C, and then slowly add Drop 40g of sodium p-aminobenzenesulfonate into the suspension, adjust the pH to 9.5-10 with 10% NaOH solution, keep stirring for about 5 hours to obtain an orange oily transparent liquid, and continue to adjust the pH to 6.5 with dilute hydrochloric acid ~7.5; Finally, add about 3 times of absolute ethanol to precipitate a reddish-brown precipitate, and dry the precipitate to obtain a modified polymer scale inhibitor.

[0027] Step 2, the preparation method of activated sodium lignosulfonate is as follows: Add 20 g of sodium lignosulfonate, 1.0 g of ferrous sulfate and 80 g of water in sequence in a stirred reactor, stir and heat up to 65 ° C, dropwise add 10g of hydrogen peroxide, heat-preserved and stirred for about 1 hour to obt...

Embodiment 3

[0030] Step 1, the preparation method of the modified polymer scale inhibitor: add 20g of polysuccinimide and 20mL of water into a reactor with a stirring and condensing device, stir for 0.5h, then raise the temperature to 75°C, and then slowly add Drop 50g of sodium p-aminobenzenesulfonate into the suspension, adjust the pH to 9.5-10 with 10% NaOH solution, keep stirring for about 6 hours to obtain an orange oily transparent liquid, continue to adjust the pH to 6.5 with dilute hydrochloric acid ~7.5; Finally, add about 4 times of absolute ethanol to precipitate a reddish-brown precipitate, and dry the precipitate to obtain a modified polymer scale inhibitor.

[0031] Step 2, the preparation method of activated sodium lignosulfonate is as follows: Add 20 g of sodium lignosulfonate, 0.8 g of ferrous sulfate and 80 g of water in sequence in a stirred reactor, stir and heat up to 50 ° C, dropwise add 6g of hydrogen peroxide, heat-retained and stirred for about 2 hours to obtain a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com