Preparation method of high-toughness cement-based composite material

A composite material, cement-based technology, applied in cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve the problems of insufficient strength, poor toughness, and short setting time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

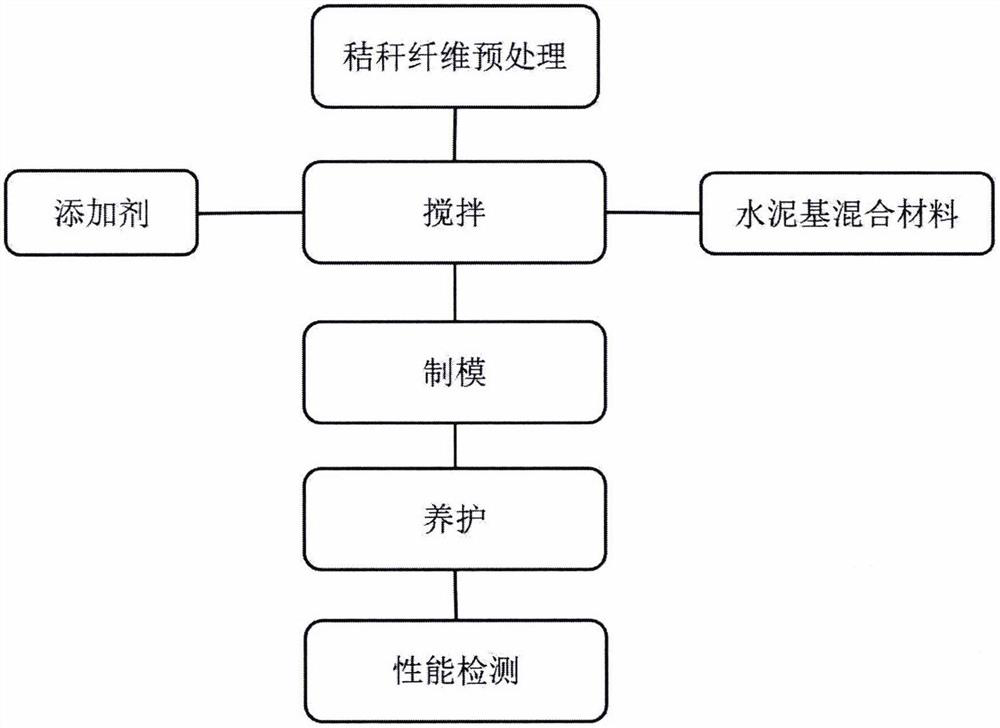

Method used

Image

Examples

Embodiment 1

[0023] This embodiment provides a method for preparing a high-toughness cement-based composite material, in terms of mass fraction: 1000Kg of ordinary Portland cement, 100kg of fiber, 3000kg of sand, and 600kg of water;

[0024] This program provides the preparation method of the above-mentioned high-toughness cement-based composite material, including the following steps:

[0025] Step 1: Weigh the plant fibers according to the components of the cement, soak them in 5% sodium hydroxide solution for 12 hours and take them out for later use;

[0026] Step 2: Stir the plant fibers treated in Step 1 with cement and sand for 2 minutes;

[0027] Step 3: Stir the mixture evenly in Step 2, add water with a water consumption of 2 / 3, and continue stirring for 2 to 3 minutes;

[0028] Step 4: Add the water reducer to the mixture obtained in Step 3 and stir with 1 / 3 of the water

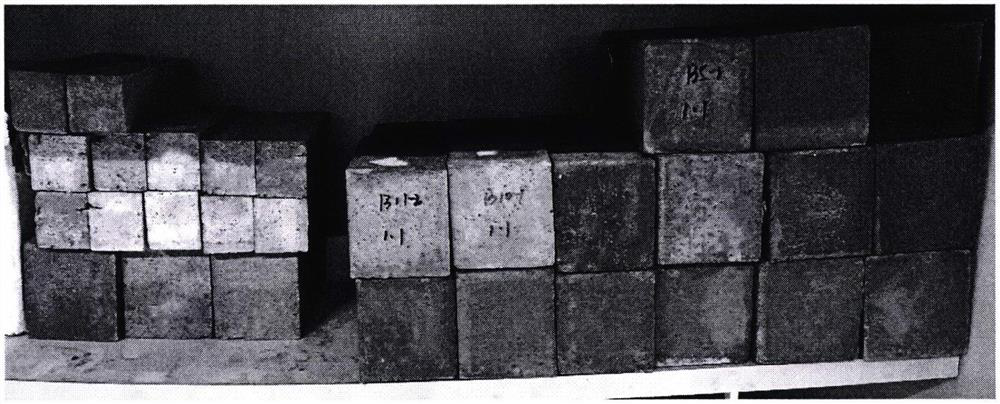

[0029] Step 5: Then pour it into the mold of the mortar test block, wait for no less than 24 hours to remo...

Embodiment 2

[0031] This embodiment provides a preparation method of a high-toughness cement-based composite material, in terms of mass fraction: 1000Kg of ordinary Portland cement, 150kg of fiber, 2800kg of sand, and 550kg of water;

[0032] This program provides the preparation method of the above-mentioned high-toughness cement-based composite material, including the following steps:

[0033] Step 1: Weigh the plant fibers according to the components of the cement, soak them in 5% sodium hydroxide solution for 12 hours and take them out for later use;

[0034] Step 2: Stir the plant fibers treated in Step 1 with cement and sand for 2 minutes;

[0035] Step 3: Stir the mixture evenly in Step 2, add water with a water consumption of 2 / 3, and continue stirring for 2 to 3 minutes;

[0036] Step 4: Add the water reducer to the mixture obtained in Step 3 and stir with 1 / 3 of the water

[0037] Step 5: Then pour it into the mold of the mortar test block, wait for no less than 24 hours to rem...

Embodiment 3

[0039] This embodiment provides a preparation method of a high-toughness cement-based composite material, in terms of mass fraction: 1000Kg of ordinary Portland cement, 200kg of fiber, 2900kg of sand, and 500kg of water;

[0040] This program provides the preparation method of the above-mentioned high-toughness cement-based composite material, including the following steps:

[0041] Step 1: Weigh the plant fibers according to the components of the cement, soak them in 5% sodium hydroxide solution for 12 hours and take them out for later use;

[0042] Step 2: Stir the plant fibers treated in Step 1 with cement and sand for 2 minutes;

[0043] Step 3: Stir the mixture evenly in Step 2, add water with a water consumption of 2 / 3, and continue stirring for 2 to 3 minutes;

[0044] Step 4: Add the water reducer to the mixture obtained in Step 3 and stir with 1 / 3 of the water

[0045] Step 5: Then pour it into the mold of the mortar test block, wait for no less than 24 hours to rem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com