Method for improving performance of Co(OH)2 supercapacitor through double-potential interval activation

A supercapacitor and bipotential technology, applied in electrolytic capacitors, hybrid capacitor electrodes, hybrid capacitor electrolytes, etc., can solve the problems of increasing process steps, long time consumption, and corrosion of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

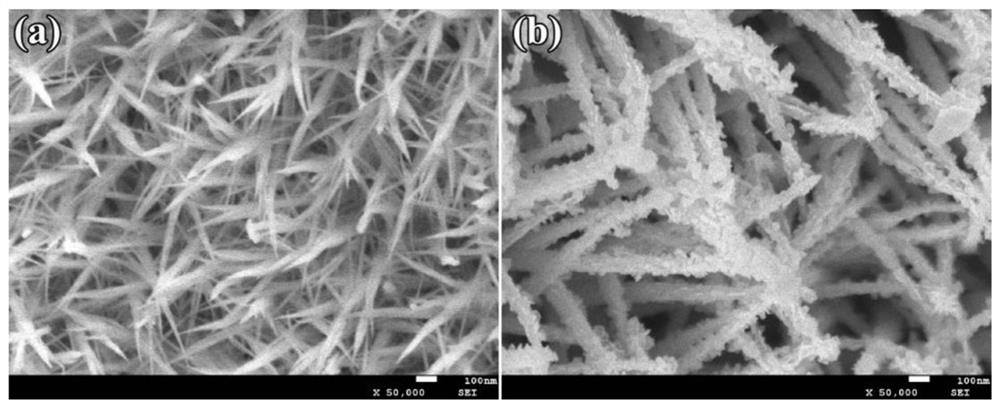

[0020] (1) Preparation of Co(OH) 2 Precursor: Nickel foam with an area of 2cm×4cm was ultrasonically cleaned with 1M hydrochloric acid solution, deionized water and absolute ethanol in sequence and dried for later use. Weigh 4mmol of cobalt nitrate and 20mmol of urea and dissolve them in 40mL of deionized water. After obtaining a transparent solution under the action of ultrasound, pour the solution into a 50mL reactor liner, and put in clean nickel foam, seal it with a stainless steel jacket, and put it in In a constant temperature drying oven at 95°C, keep warm for 6 hours. After the reaction kettle drops to room temperature, take out the foamed nickel, rinse the surface of the foamed nickel repeatedly with deionized and absolute ethanol, and dry it under natural conditions to obtain Co(OH) 2 Precursor.

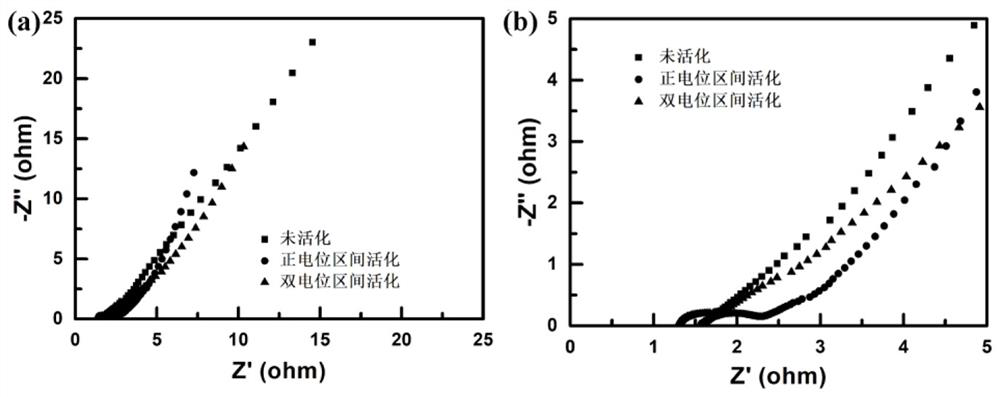

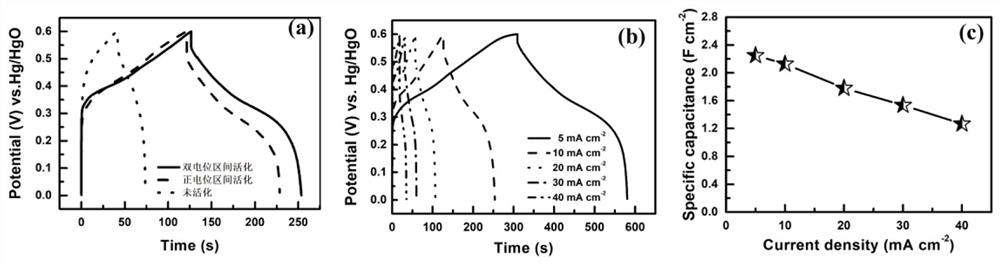

[0021] (2) Activation of Co(OH) in the positive potential range 2 : Configure a KOH solution with a concentration of 1M as the electrolyte, and use the Co(OH) obtained ...

Embodiment 2

[0027] Compared with Example 1, step (2) activates Co(OH) in the positive potential range 2 In , the number of scanning circles was adjusted to 10 circles, and the other steps and experimental parameters were kept unchanged. The prepared samples were at 10 mA cm -2 2.1 F cm capacity at current density -2 .

Embodiment 3

[0029] Compared with Example 1, step (2) activates Co(OH) in the positive potential range 2 , the scan rate is adjusted to 30 mV s -1 , the number of scanning circles was adjusted to 20 circles, and the other steps and experimental parameters were kept unchanged. The prepared samples were -2 The capacity at current density is 2.12 F cm -2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com