Thiosemicarbazide functionalized graphene oxide/chitosan composite adsorbent as well as preparation method and application thereof

A technology of thiosemicarbazide and composite adsorption, which is applied in chemical instruments and methods, adsorption water/sewage treatment, and other chemical processes, can solve problems such as weak bonding, complicated preparation steps, and material loss, and achieve good and reproducible properties, the preparation method is simple, and the effect of increasing the adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

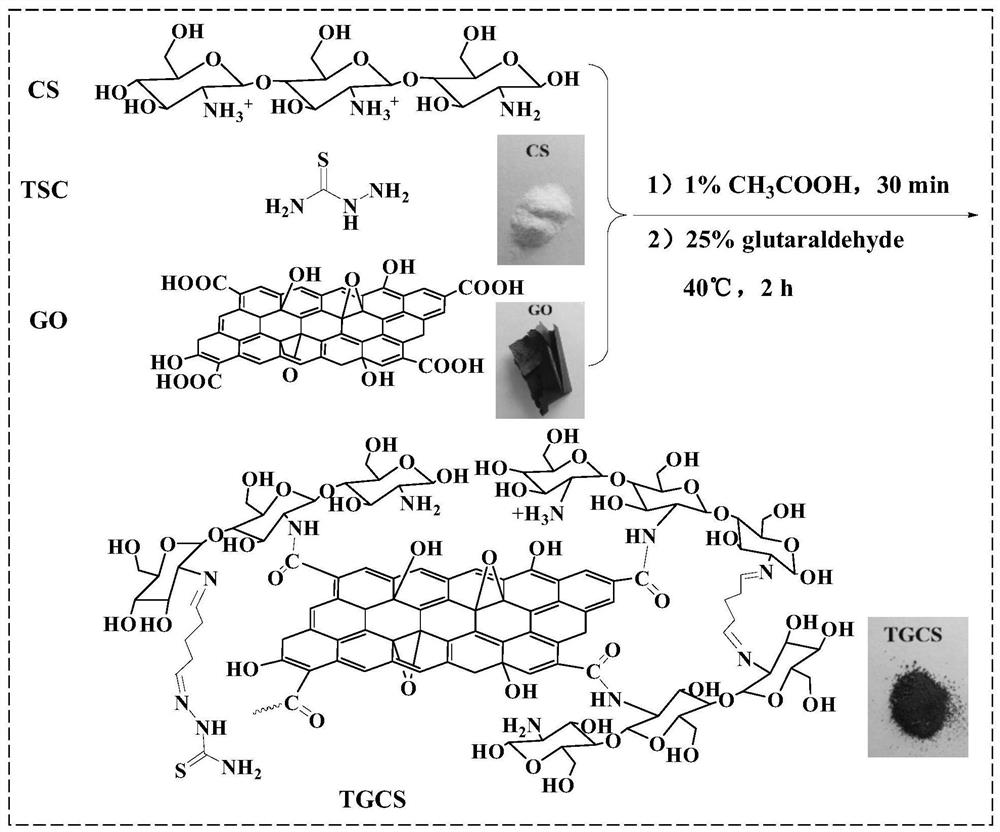

[0045] The preparation steps of the provided thiosemicarbazide functionalized graphene oxide / chitosan composite adsorbent are as follows:

[0046] (1) 0.5g of chitosan was added to a 250mL single-necked flask, and 100mL of 1% acetic acid solution was added to make it a pale yellow viscous mixture.

[0047] (2) Disperse 100 mg of graphene oxide into 20 mL of distilled water, and then add the graphene oxide dispersion into the mixture described in step (1).

[0048] (3) Add 100 mg of thiosemicarbazide solid directly into the dispersion system described in step (2), and stir at 30° C. for 30 minutes to disperse the components evenly.

[0049] (4) Add 1 mL of glutaraldehyde to the dispersion system described in step (3), and stir at 40° C. for 2 h.

[0050] (5) Add the mixture obtained in step (4) to 100mL 0.5mol / L NaOH solution, use a 50mL centrifuge tube, centrifuge at 10000rpm for 1min, wash the obtained precipitate with distilled water, repeat the washing-centrifugation cycle 3...

Embodiment 2

[0053] The preparation steps of the provided thiosemicarbazide functionalized graphene oxide / chitosan composite adsorbent are as follows:

[0054] (1) 1.0g of chitosan was added to a 250mL single-necked flask, and 100mL of 1% acetic acid solution was added to make it a pale yellow viscous mixture.

[0055] (2) Disperse 100 mg of graphene oxide into 20 mL of distilled water, and then add the graphene oxide dispersion into the mixture described in step (1).

[0056] (3) Add 200 mg of thiosemicarbazide solid directly into the dispersion system described in step (2), and stir at 30° C. for 30 minutes to disperse the components evenly.

[0057] (4) Add 1 mL of glutaraldehyde to the dispersion system described in step (3), and stir at 40° C. for 2 h.

[0058] (5) Add the mixture obtained in step (4) to 70mL 0.5mol / L NaOH solution, use a 50mL centrifuge tube, centrifuge at 8000rpm for 2min, wash the obtained precipitate with distilled water, repeat the washing-centrifugation cycle 3...

Embodiment 3

[0061] The preparation steps of the provided thiosemicarbazide functionalized graphene oxide / chitosan composite adsorbent are as follows:

[0062] (1) 1.5g of chitosan was added to a 250mL single-necked flask, and 70mL of 2% acetic acid solution was added to make it a pale yellow viscous mixture.

[0063] (2) Disperse 100 mg of graphene oxide into 10 mL of distilled water, then add the graphene oxide dispersion into the mixture described in step (1).

[0064] (3) Add 200 mg of thiosemicarbazide solid directly into the dispersion system described in step (2), and stir at 30° C. for 30 minutes to disperse the components evenly.

[0065] (4) Add 1 mL of glutaraldehyde to the dispersion system described in step (3), and stir at 40° C. for 2 h.

[0066] (5) Add the mixture obtained in step (4) to 120mL 0.5mol / L NaOH solution, use a 50mL centrifuge tube, centrifuge at 8000rpm for 1min, wash the obtained precipitate with distilled water, repeat the washing-centrifugation cycle 3 tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com