Preparation method and application of magnetic diatomite composite powder carrier material

A composite powder and carrier material technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., to achieve the effect of accelerated separation, large specific surface area, and improved biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A preparation method of magnetic diatomite composite powder carrier material, comprising the following steps:

[0040] (1) Take 1-10g of diatomite powder, put it in a 500mL beaker, and add 200-400mL of deionized water;

[0041] (2) Place the beaker in step (1) in a heat-collecting constant temperature magnetic stirrer for stirring treatment for 15-100 minutes to form a relatively uniform dispersion;

[0042] (3) Heat the dispersion liquid in step (2) in a water bath for 2 to 12 hours under the condition of magnetic stirring. 2 4H 2 O, the solution is brown-green;

[0043] (4) Gradually add 0.5 to 10 g of FeCl to the solution in step (3) under the condition of magnetic stirring 3 , and at the same time raise the temperature to 75-85°C, at this time the solution turns black, and keep stirring for 2-5 hours;

[0044] (5) In the case of magnetic stirring, add 0.25 to 1.5 mol / L of Na dropwise to the solution in step (4) 2 S solution, adjust the pH value to 11;

[0045] (...

Embodiment 2

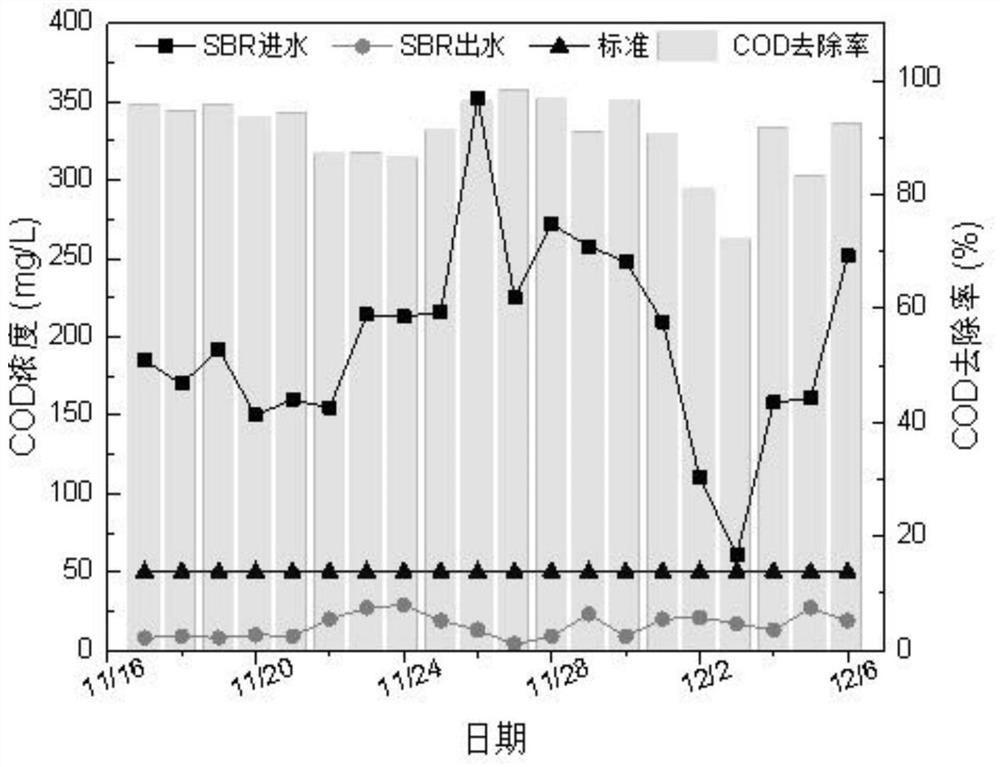

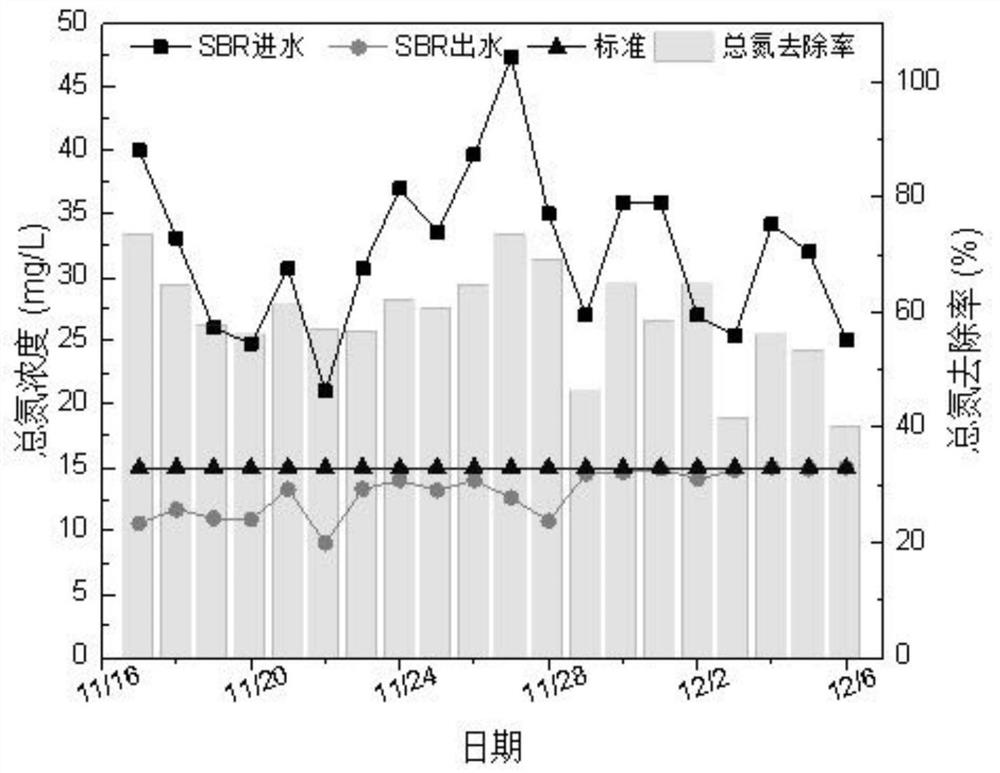

[0050] A kind of application of magnetic diatomite composite powder carrier material, comprises the following steps:

[0051] (1) Add the magnetic diatomite composite powder carrier material prepared in Example 1 into the SBR process;

[0052] (2) The sewage treatment process adopts the SBR process, which mainly includes the water inlet section, the stirring section, the aeration section, the sedimentation section, the drainage section and the static section;

[0053] (3) The water retention time in the SBR process is 4 to 12 hours, and the sludge retention time is 12 to 30 days;

[0054] (4) According to the mixed sludge concentration (MLSS) in the aerobic section, the dosage of magnetic diatomite composite powder carrier material is 0-5% of MLSS;

[0055] (5) After adding magnetic diatomite composite powder carrier material, the sludge concentration can reach 5000-12000mg / L;

[0056] (6) After the operation is stable, the sewage treatment capacity is increased to 1-3 times...

Embodiment 3

[0058] (1) In the drainage stage in embodiment 2, channel-type drainage pipes are set, such as Figure 4 shown;

[0059] (2) The sludge flows from the 1-biological reaction tank to the drainage channel through the 2-sewage overflow port;

[0060] (3) The sludge in step (2) enters the 4-complete return channel and the 5-rotating magnetic field channel through the 10-flow regulating weir plate regulation sludge, and enters the 4-through the opening and closing degree of the 10-flow regulating weir plate. - The adjustment ratio in the complete backflow channel is 0-100%;

[0061] (4) The sludge entering the 4-full return channel is directly returned to the biochemical reaction unit;

[0062] (5) Under the action of the magnetic plate, the sludge entering the 5-rotating magnetic field channel is adsorbed at the bottom of the 6-conveyor belt, while the non-magnetic sludge flows out of the 5-rotating magnetic field channel and is discharged as residual sludge ;

[0063] (6) Drive...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap