Full-tailing mine underground filling method

An underground and full tailings technology, which is applied in the field of full tailings underground filling, can solve the problems of high tailings loss, poor filling quality, and slow condensation of full tailings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Example 1: Selection of filling slurry retarding inhibitor

[0056] The existence of smithsonite is the key factor leading to the retardation of filling slurry, so it is necessary to investigate which inhibitors can eliminate the retardation phenomenon caused by smithsonite through the reaction process. Add cement (P.O 42.5), retarding inhibitor and water to the whole tailings to prepare filling slurry, then cast the prepared filling slurry and demould, and record the demoulding time. The test results are shown in Table 1 .

[0057] Sodium hydrosulfide and trisodium phosphate are selected as retarding inhibitors, which can form precipitates with zinc. In the experiment, NaHS, Na 3 PO 4 The dosage is 0.25% of the tailings weight. In addition, zinc ions consume part of calcium ions during cement hydration, resulting in insufficient calcium ions in the slurry. The test intends to investigate the effect of alkalinity on shortening the demoulding time by adding a small ...

Embodiment 2

[0061] Embodiment 2: The influence of sulfide additive on demoulding time of test piece

[0062] Investigate the effects of retarder inhibitor agent types, agent dosage, and different lime-sand ratios on the demoulding time of the test block. specific:

[0063] (1) Method: Add cement (P.O 42.5), different amounts of sodium hydrosulfide and water to the whole tailing sand to prepare filling slurry (lime-sand ratio 1:4, filling concentration 72%), and then mix the prepared The filling slurry was poured and demoulded, and the demoulding time was recorded. The test results are shown in Table 2.

[0064] Table 2 Effect of NaHS dosage on demoulding time

[0065]

[0066] It can be seen from Table 2 that with the increase of the dosage of sodium hydrosulfide, the demoulding time of the slurry is continuously shortened, from 120h with zero addition of sodium hydrosulfide to within 8h. From the perspective of economy and environmental protection, when the amount of sodium hydrosu...

Embodiment 3

[0075] Embodiment 3: Filling material strength ratio

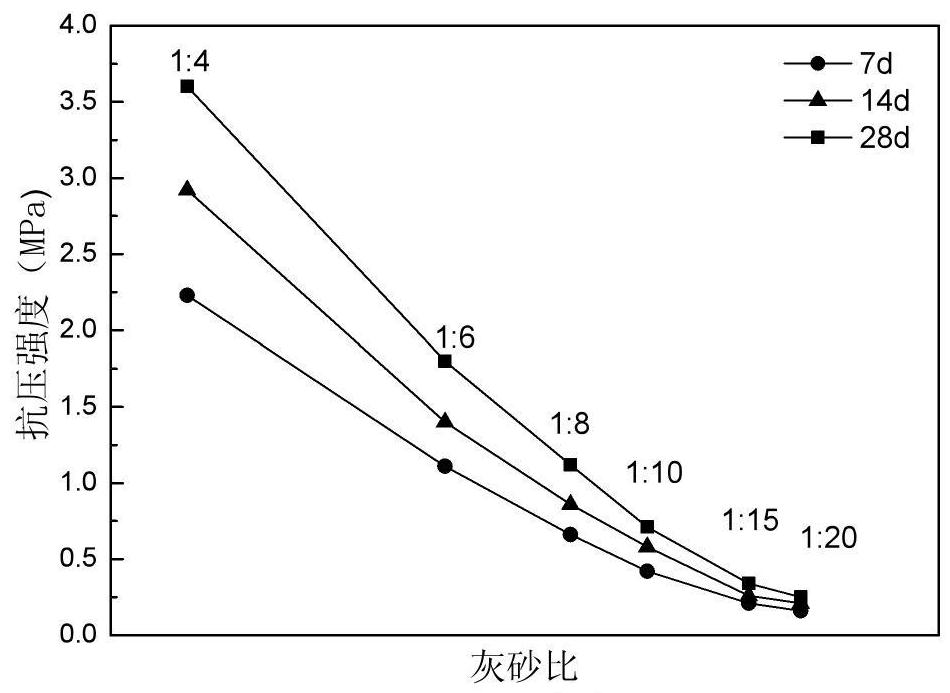

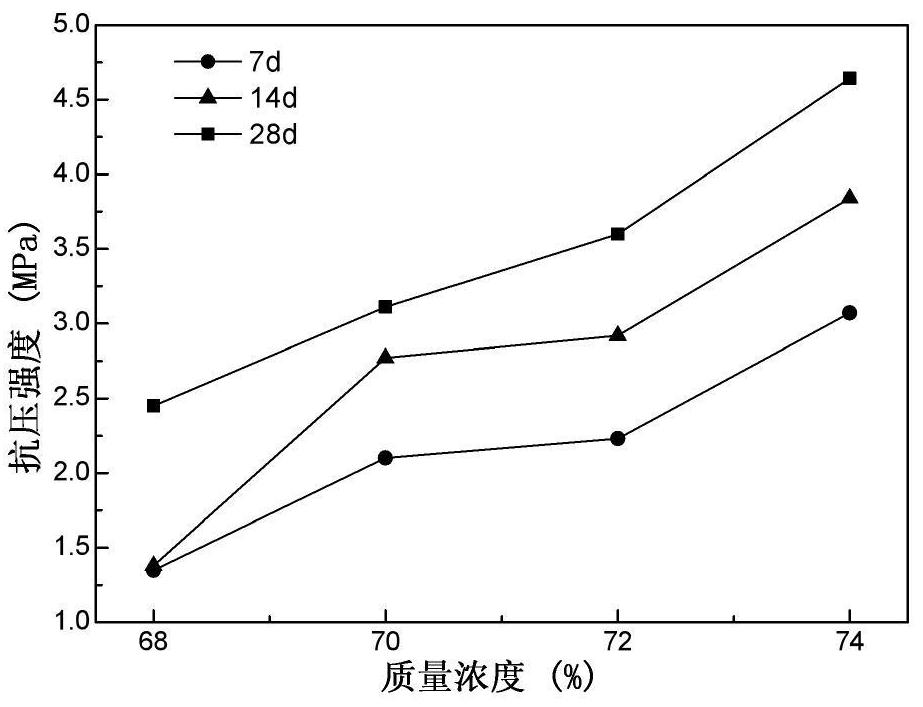

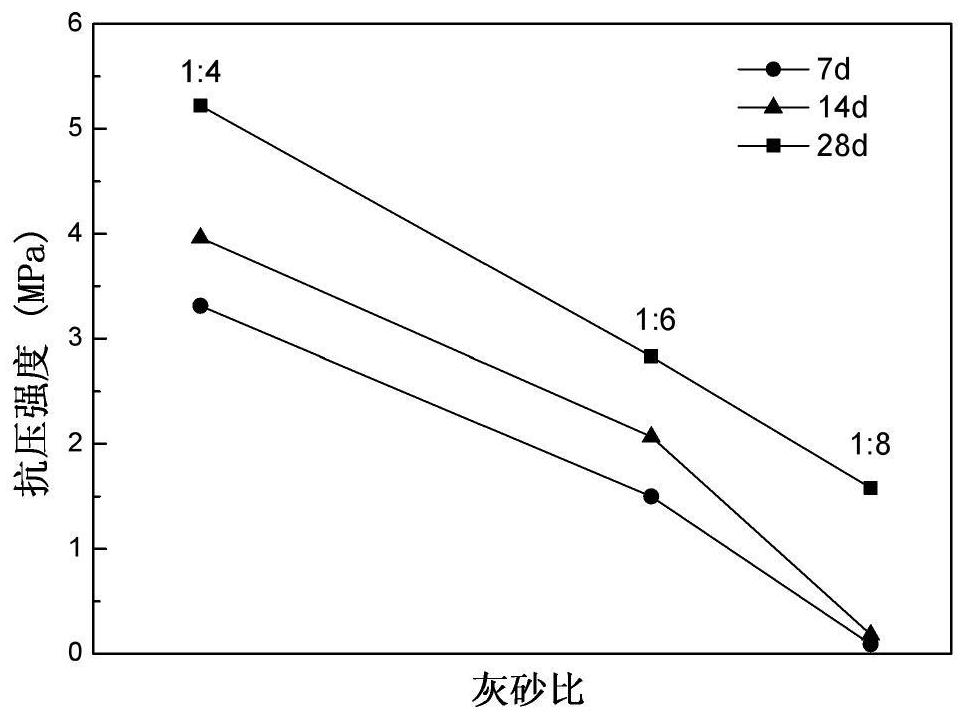

[0076] The raw material used in the test is the whole tailings of Xinjiang Zijin Zinc Industry, the cement is Tianshan brand ordinary Portland cement (P.O42.5), and the additive is sodium hydrosulfide solution (content 21.14%, provided by Zijinshan Gold and Copper Mine). According to the results of the slump test, it is determined that the filling ratio test of the whole tailings is 6 groups of lime-sand ratios: 1:4, 1:6, 1:8, 1:10, 1:15, and 1:20. There are 4 groups of 68%, 70%, 72%, and 74%. Each group is tested for compressive strength at four ages of 7d, 14d, 28d, and 60d. Two test blocks are poured for each age, and each group is supplemented with 2 A total of 240 test blocks were used to test the bulk density of each age.

[0077] The test process is as follows: After weighing the tailings, cement, sodium hydrosulfide and water according to the proportion, firstly mix the tailings and cement evenly, then add sodium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com