Halogen-free flame retardant and application thereof in preparation of halogen-free flame-retardant PA6

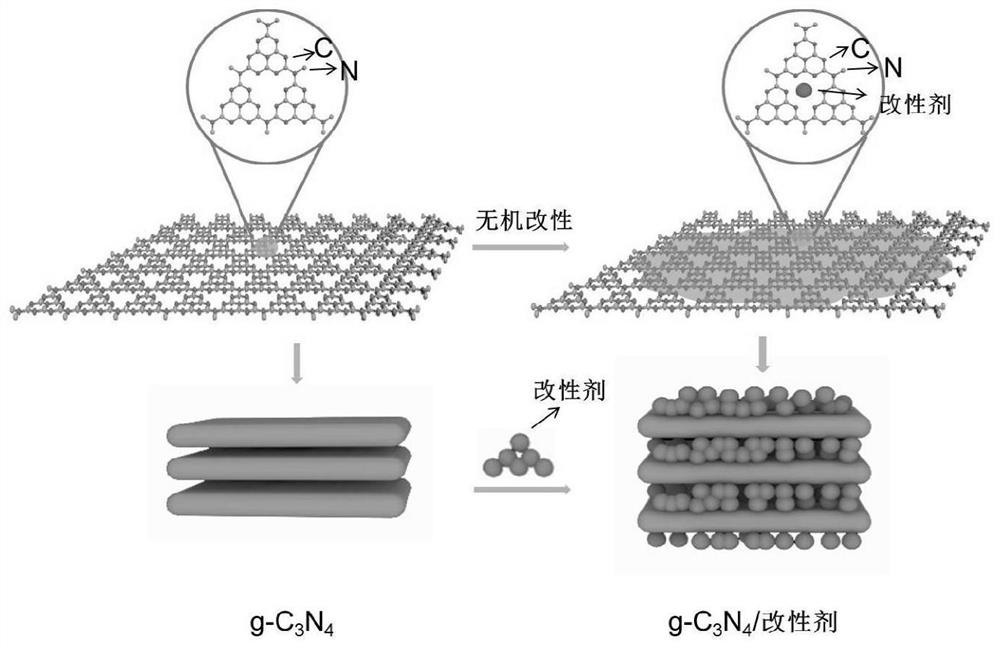

A technology of flame retardant and graphite phase carbon nitride, which is applied in the field of polymer flame retardant materials, can solve the problems that the flame retardant effect cannot be fully exerted and is difficult to disperse, and achieve uniform dispersion and stability, and strengthen uniform dispersion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

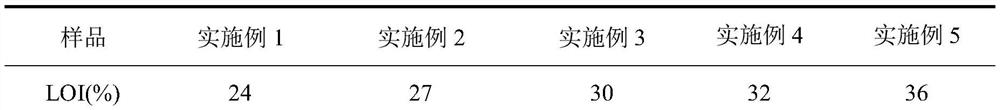

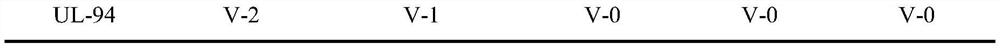

[0025] Weigh 500g of caprolactam in the reaction kettle, add 40mL of distilled water into the reaction kettle, pass through nitrogen and vacuumize, go through 5 cycles to exhaust the air in the kettle, stir fully, raise the temperature to 255°C, maintain the pressure at 0.55MPa, and react 4h, release the pressure to normal pressure, keep vacuuming, and fill with nitrogen for 1.5h; Dry in a drying oven at 95°C to obtain PA6 material. Sample preparation of the obtained product was carried out for combustion performance test, and the results are shown in Table 1.

Embodiment 2

[0027] Weigh 10g of melamine and place it in a crucible, wrap it with tin foil, calcinate at 600°C for 4h, take it out after it is naturally cooled to room temperature, wash it with distilled water, filter it with suction, and dry it; put 5g g-C 3 N 4 Mix with 495g caprolactam in the reaction kettle, heat to 95°C, stir for 1 hour to obtain a uniform mixture; add 40mL distilled water to the reaction kettle, feed nitrogen and vacuumize, cycle 5 times, exhaust the air in the kettle, stir, and heat up To 255°C, maintain the pressure at 0.55MPa, react for 4 hours, release the pressure to normal pressure, continue vacuuming, and fill with nitrogen for 1.5 hours; times; dry the obtained product in a vacuum drying oven at 95°C to obtain a flame-retardant PA6 composite material. Sample preparation of the obtained product was carried out for combustion performance test, and the results are shown in Table 1.

Embodiment 3

[0029] Weigh 10g of melamine and 8.37g of magnesium chloride hexahydrate, mix them evenly, dry them at 50°C, place them in a crucible, wrap them in tin foil, and calcinate them at 600°C for 4h, after they are naturally cooled to room temperature, take them out, wash them with distilled water, filter them with suction, and bake them. dry; 5 g of prepared g-C 3 N 4 / MgO and 495g caprolactam were mixed in a reaction kettle, heated to 95°C, stirred for 1 hour to obtain a uniform mixture; 40mL of distilled water was added to the reaction kettle, nitrogen was introduced and vacuumized, and the air in the kettle was exhausted after 5 cycles. Stir well, raise the temperature to 255°C, maintain the pressure at 0.55MPa, react for 4 hours, release the pressure to normal pressure, continue vacuuming, and fill with nitrogen for 1.5 hours; after the reaction, the product is cooled and drawn in water, pelletized and extracted in boiling water for 10 hours , changing the water 5 times; dryin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com