Liquid metal phase change heat absorption material

A liquid metal phase and heat-absorbing material technology, applied in heat exchange materials, microcapsule preparations, chemical instruments and methods, etc., can solve the problem of affecting the overall heat absorption efficiency of liquid metal phase change materials, and the heat of electronic devices cannot be dissipated in time , burnout of electronic devices and other problems, to achieve the effect of reducing surface tension, reducing supercooling, and avoiding sedimentation and stratification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

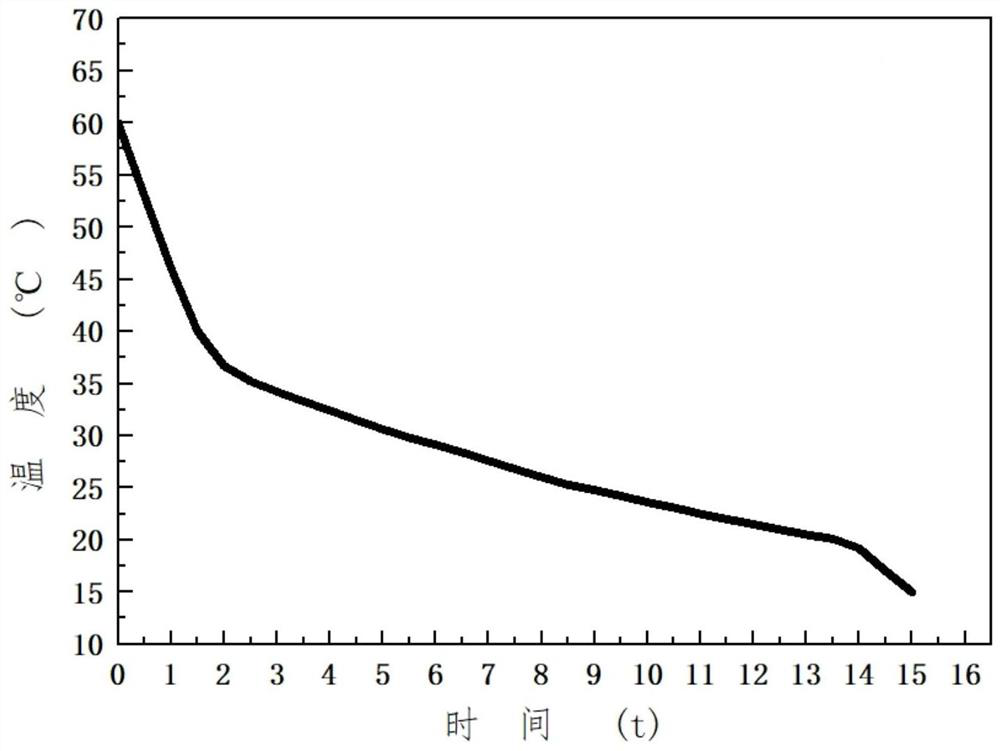

[0031] Example 1 tested the step cooling curve of the liquid metal phase change endothermic material with a phase change point range of 20-40°C of the present invention at an ambient temperature of 15°C. figure 1 It is the step cooling curve of the liquid metal phase-change endothermic material of the present invention at an ambient temperature of 15°C.

[0032] In this embodiment, a liquid metal phase-change endothermic material is characterized in that it contains a low melting point metal, gallium oxide, tin hydroxide, and phase-change microcapsules.

[0033] In this embodiment, the total mass of materials is 300g, the mass fraction of low melting point metal is 80%, the mass fraction of gallium oxide is 0.5%, the particle size is 10 microns, the mass fraction of tin hydroxide is 0.5%, and the particle size is 10 microns , the mass fraction of phase change microcapsules is 19%.

[0034] The preparation of the phase change endothermic material of the present invention compr...

Embodiment 2

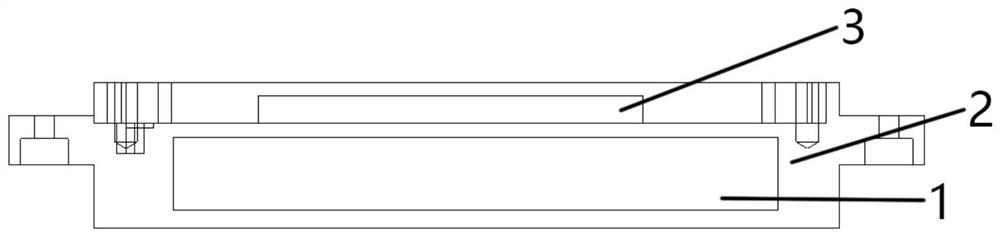

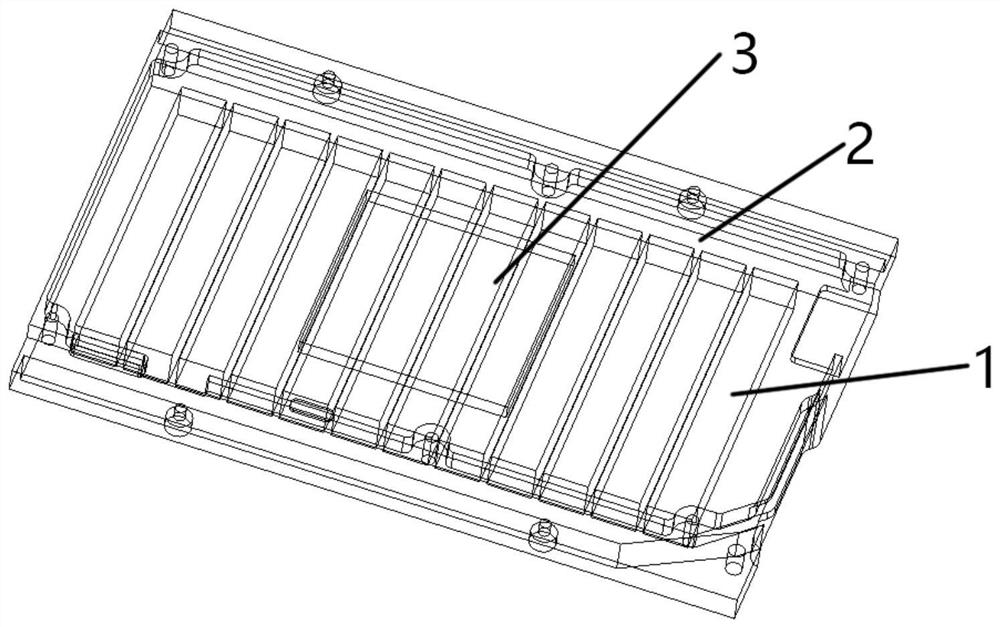

[0042] figure 2 with image 3 A typical application of the liquid metal phase-change endothermic material of the present invention in cooling and thermal management systems is shown. figure 2 It is a structural schematic diagram of the application of the liquid metal phase-change endothermic material of the present invention in cooling and thermal management systems. Among them: 1-liquid metal phase change heat absorbing material, 2-copper refrigeration plate, 3-radio frequency chip.

[0043]A liquid metal phase-change endothermic material in this embodiment, the mass fraction of low-melting point metal is 85%, the mass fraction of gallium oxide is 1%, the particle diameter is 8 microns, the mass fraction of tin hydroxide is 1%, and the mass fraction is 1%. The diameter is 8 microns, and the mass fraction of phase change microcapsules is 13%.

[0044] When in use, the liquid metal phase-change heat-absorbing material is filled in the copper refrigeration plate. The thickn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com